Ship pollution bottom monitoring evaluation method and evaluation system

An evaluation system and ship technology, applied in ship parts, ship construction, ship design, etc., can solve the problems of high cost of evaluation methods, inability to consider the impact of ship performance evaluation, large human and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

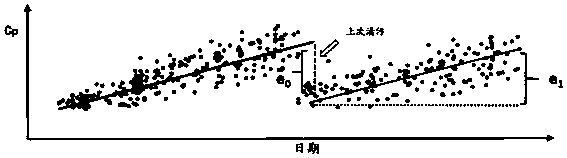

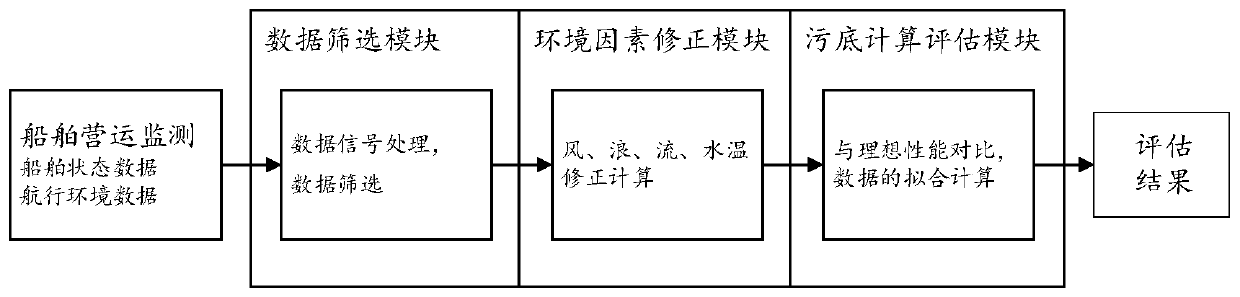

[0055] see Figure 1-5 As shown, the embodiments of the present invention first provide a kind of ship fouling monitoring and evaluation method, realized by the following technical solutions:

[0056] 1. Collect ship operation data, including the following ship status data: ship draft, speed engine power, speed engine speed, ship speed over ground, ship speed over water, ship rudder angle, ship heading angle, ship motion, and navigation environment;

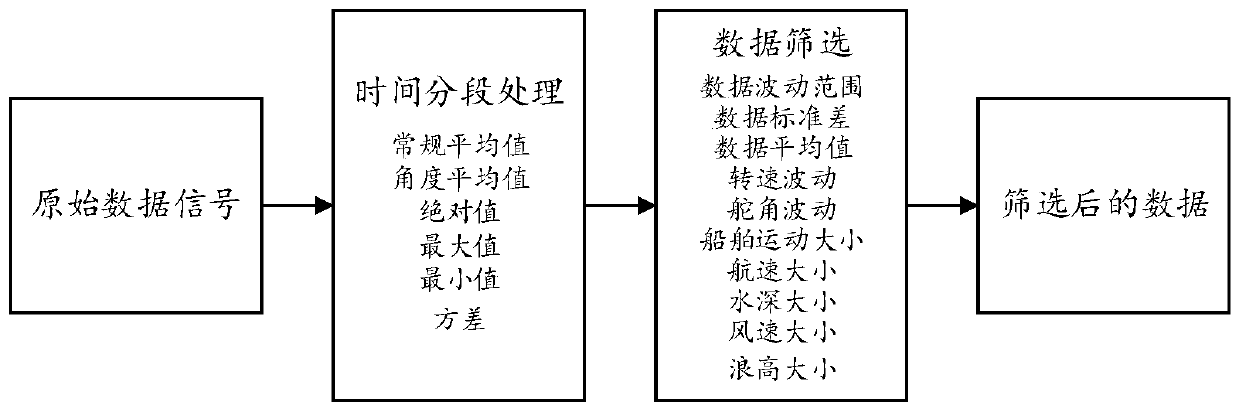

[0057] 2. Perform quality screening on the data collected in step 1; first, time-segment processing is performed on these data with every ten minutes as a fixed time period, so as to convert higher-frequency signals into time-averaged signals; Statistical analysis of the data to obtain its absolute value, maximum and minimum value, and standard deviation statistical value; af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com