Transfer device for automobile intelligent manufacturing production line

A technology of intelligent manufacturing and transfer device, applied in conveyor control device, transportation and packaging, conveyor objects, etc., can solve problems such as falling, product tilting, product stacking, etc., to avoid tilting or falling, save operation Steps, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

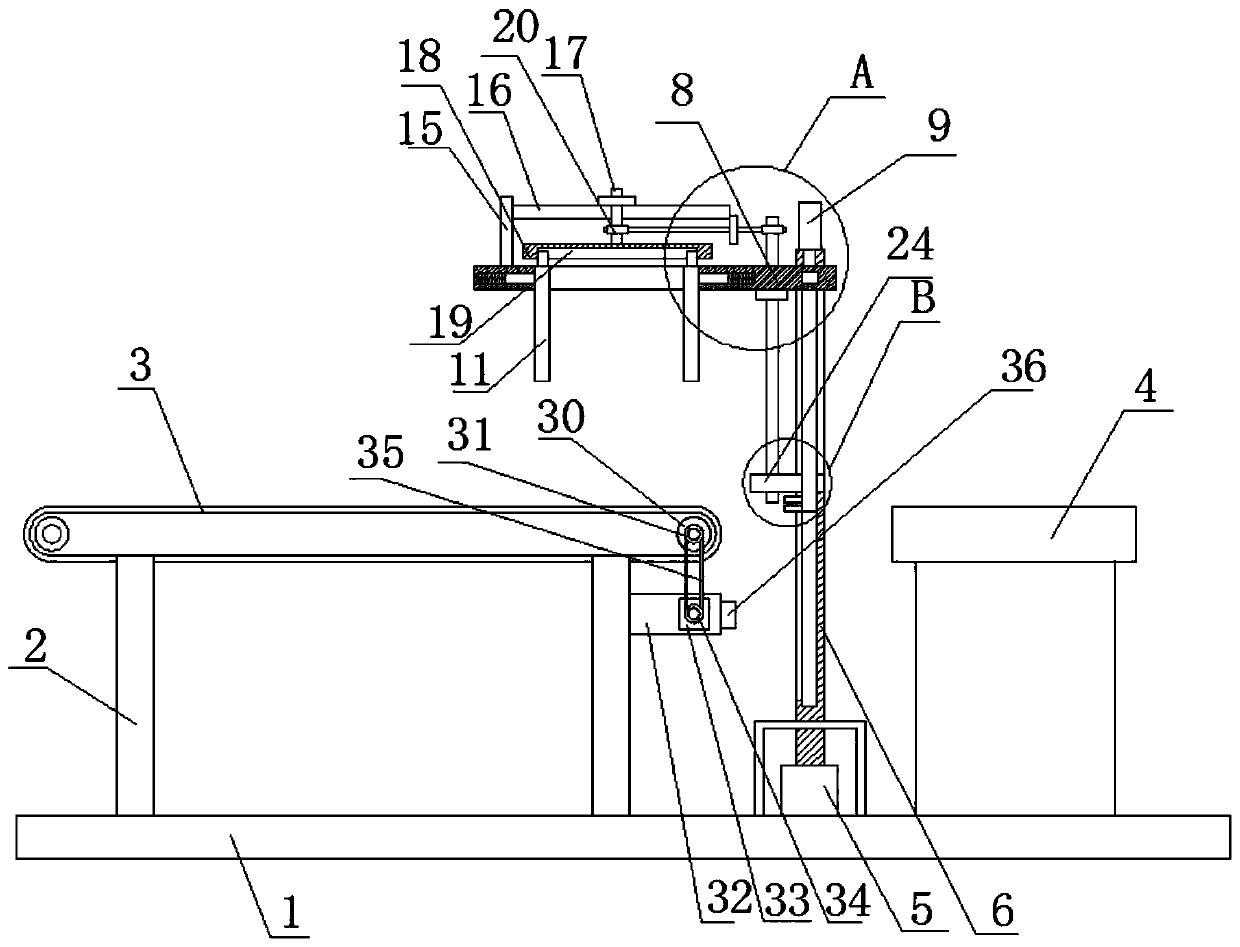

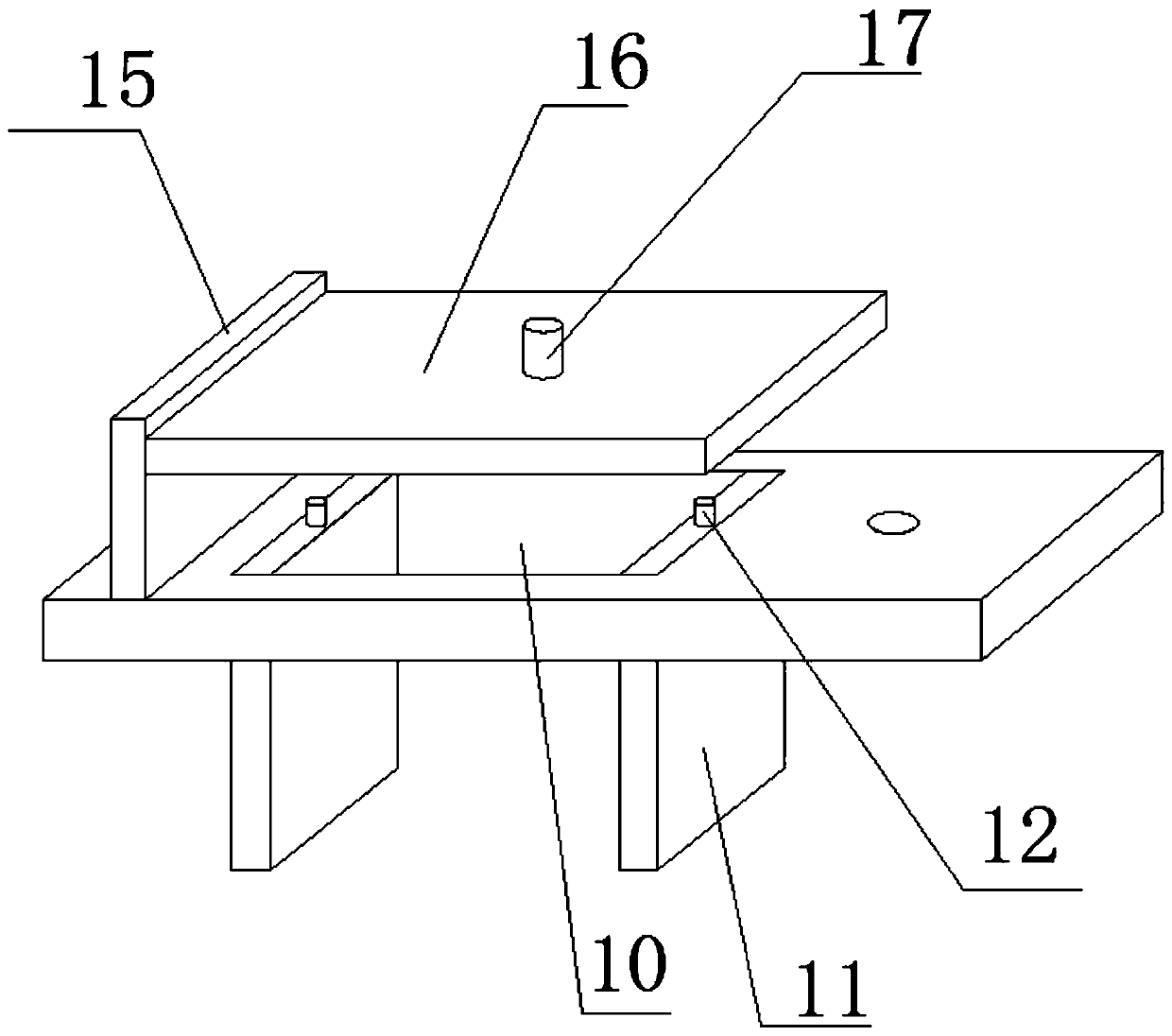

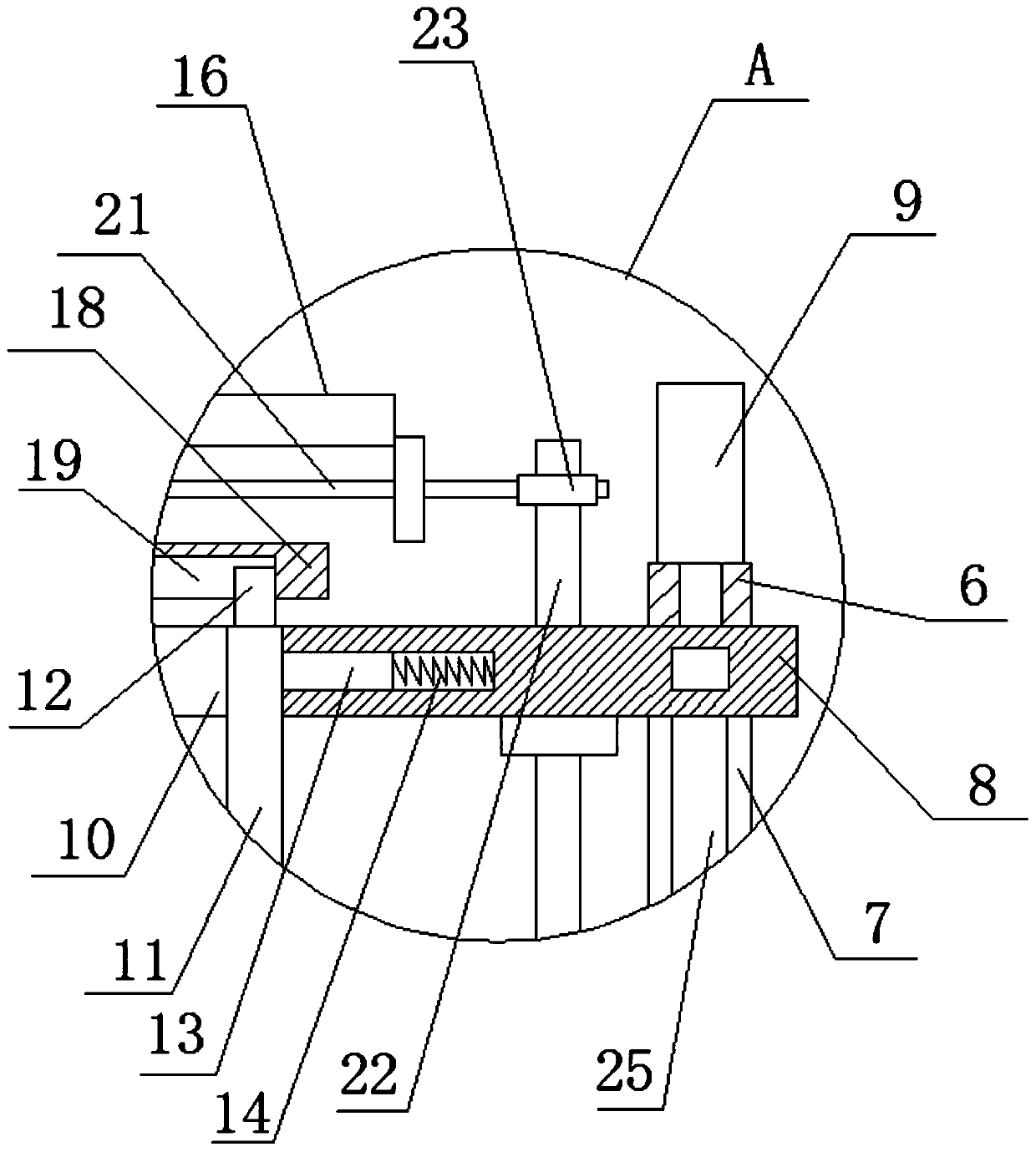

[0030] see Figure 1-5, the present embodiment provides a transfer device for an automobile intelligent manufacturing production line, including a transfer base 1, a first conveyor belt 3 and a second conveyor belt 4 are arranged on the top of the transfer base 1, and the first conveyor belt 3 and the second conveyor belt 4 are arranged vertically. The top of the transfer base 1 is fixedly equipped with a first motor 5, and the output shaft of the first motor 5 is fixedly equipped with a rotating column 6, which is located between the first conveyor belt 3 and the second conveyor belt 4, and the rotating column 6 is provided with Rectangular sliding hole 7, a rectangular sliding plate 8 is slidably installed in the rectangular sliding hole 7, a vertical hole 10 is opened on the rectangular sliding plate 8, two splints 11 are slidably installed in the vertical hole 10, and a push rod 25 is fixedly installed on the bottom of the rectangular sliding plate 8 , the outer side of th...

Embodiment 2

[0034] see Figure 1-4 , made a further improvement on the basis of Embodiment 1: the top of the transfer base 1 is fixedly installed with a protective cover, the first motor 5 is located in the protective cover, the top of the protective cover is provided with a round hole, and the outer side of the rotating column 6 is connected with the round hole The side wall is slidingly connected, and the protective cover is used to protect the first motor 5 and start the dustproof effect. The bottom of the rectangular slide 8 is fixedly equipped with a second bearing, and the transmission screw 22 is fixedly connected with the inner ring of the second bearing. The horizontal plate 16 The top of the top is fixedly installed with a third bearing, and the outer side of the vertical rod 17 is fixedly connected with the inner ring of the third bearing. The setting of the second bearing makes the transmission screw 22 rotate stably, and the setting of the third bearing makes the vertical rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com