Descaling method for oil well produced water

A technology for producing water and oil wells, which is used in mining wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., and can solve problems such as poor descaling effect and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

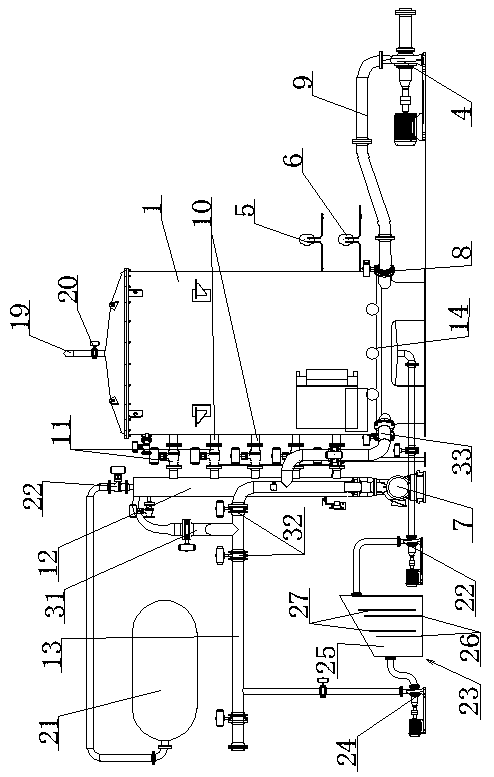

[0044] The descaling method for the produced water of the oil well is composed of a filter tank 1, a filter disc 2, a filter cartridge 3, a liquid supply pump 4, an alkali supply pump 5, a medicine supply pump 6, a booster pump 7 and a main manifold 12 (see the appendix figure 1 ).

[0045] The bottom of the filter tank 1 is connected to the liquid supply pump 4 through the liquid inlet valve 8 and the liquid inlet pipe 9; the liquid supply pump 4 is connected with the external oil well produced water storage tank; The pipe 9 feeds the oil well produced water into the filter tank 1 .

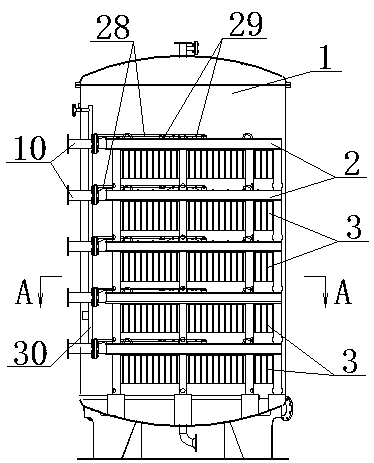

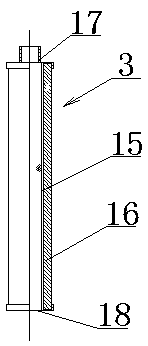

[0046] The inside of the filter tank 1 is arranged with a plurality of filter discs 2 at intervals up and down (see the attached figure 2 ); the filter disc 2 is a hollow disc-shaped structure; there is a certain gap between the periphery of the filter disc 2 and the inner wall of the filter tank 1 (see the attached Figure 5 ); in this way, after the produced water from the oil well enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com