Method for improving grindability of steel slag

An easy-grindability and steel slag technology, applied in cement production and other directions, can solve the problems of poor grindability of steel slag tailings and low recycling rate of steel slag, and achieve the effect of good grindability and poor grindability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

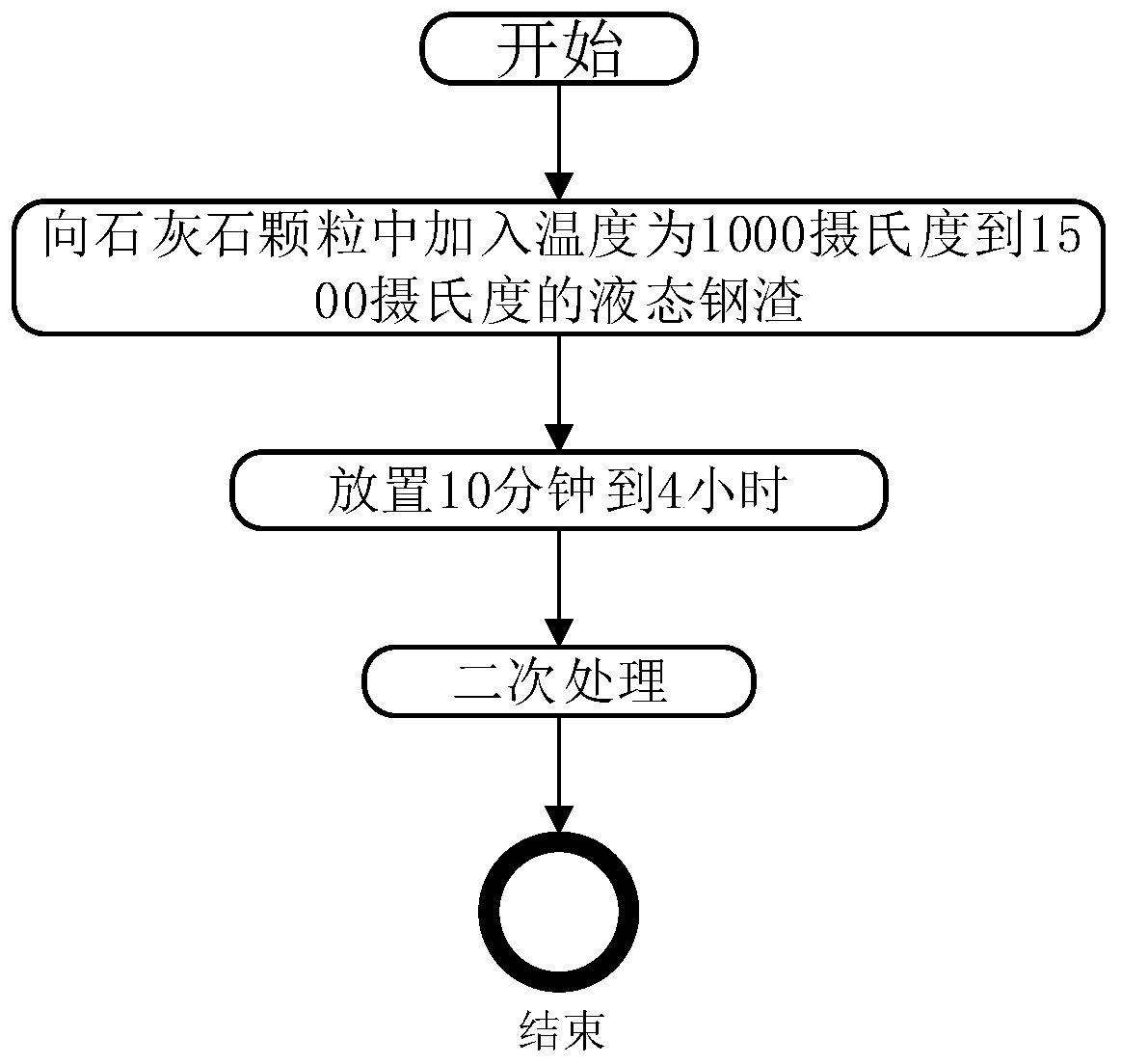

[0018] A method for improving the grindability of steel slag, comprising:

[0019] Put 500kg of dried limestone particles with a particle size of 0.1-1mm at the bottom of the slag tank, and pour 9000kg of liquid steel slag at a temperature of about 1200 degrees Celsius into the limestone, and use the impact force of the liquid steel slag poured into the bottom of the slag tank to hit the limestone to make the limestone particles Mix evenly with liquid steel slag to make limestone decompose rapidly under the heating of liquid steel slag to generate carbon dioxide gas. These carbon dioxide gases will generate holes in the liquid steel slag and form voids inside the steel slag after the steel slag cools down; pour the liquid steel slag and place it After 30 minutes, continue to process the reacted steel slag according to the normal boring process to obtain loose porous / high grindability steel slag.

Embodiment 2

[0021] Provide a method of improving the grindability of steel slag, including:

[0022] Put 500kg of dried limestone particles (particle size 1-2mm) at the bottom of the slag tank, wherein the particle size of the limestone particles is 1mm, and the moisture content of the limestone is 0.9%; then pour 9000kg of liquid steel slag with a temperature of about 1200 degrees Celsius Put limestone particles into the bottom of the slag tank, and use the impact force of liquid steel slag poured into the bottom of the slag tank to hit the limestone to make the limestone particles and liquid steel slag mix evenly, so that the limestone will be rapidly decomposed under the heating of the liquid steel slag to generate carbon dioxide gas. Holes will be generated in the liquid steel slag, and voids will be formed inside the steel slag after the steel slag cools down; after pouring the liquid steel slag, leave it for 2 hours, and then continue to process the reacted steel slag according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com