Ceramic fiber-coated suspension bridge main cable

A ceramic fiber and suspension bridge technology, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as limiting the service life of the main cable, unbalanced stress distribution, and bad social influences, and improve the quality of the main cable, balanced stress distribution, and temperature. The effect of uniform field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

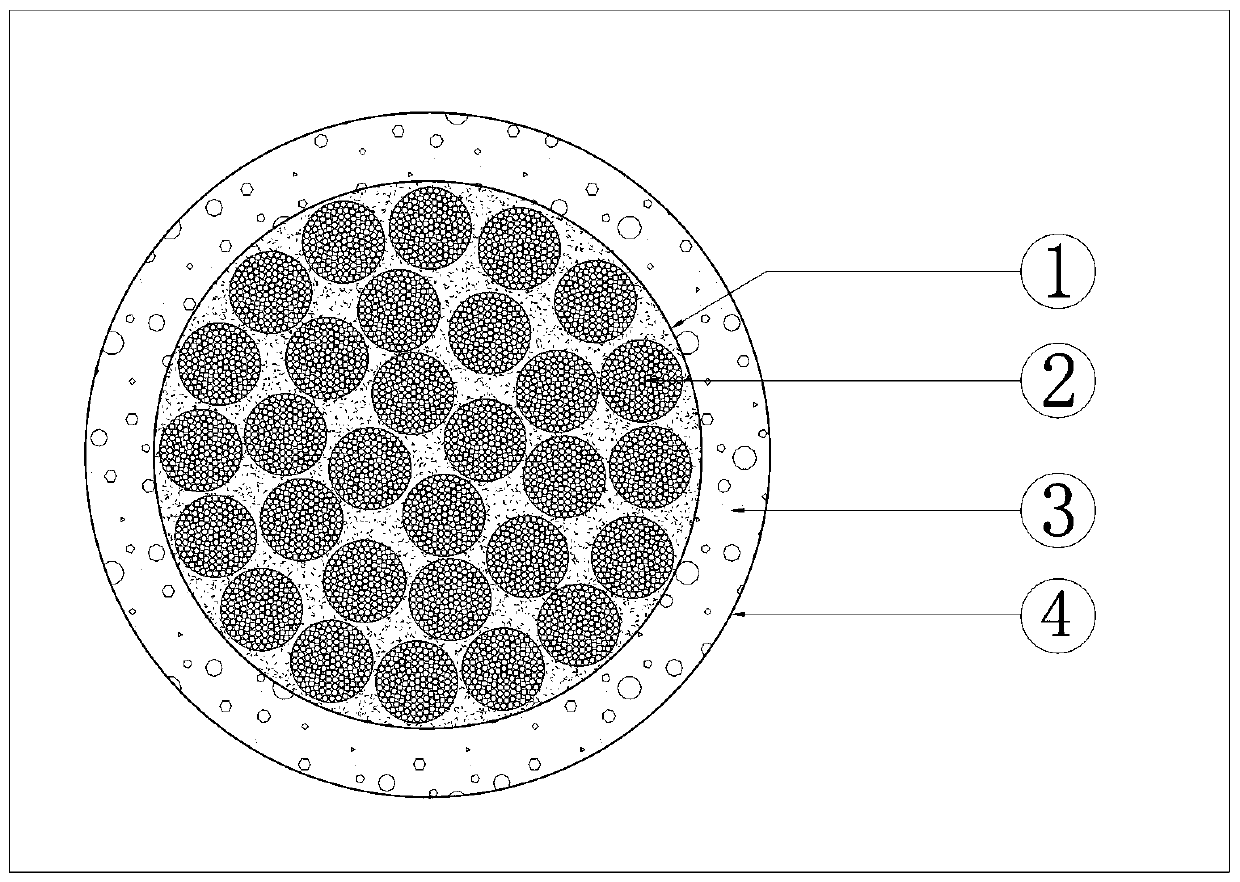

[0015] as attached figure 1 As shown: the strand sheath 1 fixes and protects several strands 2, the ceramic fiber 3 is wrapped outside the strand sheath 1, and the ceramic fiber sheath 4 fixes and protects the ceramic fiber 3.

[0016] The ceramic fiber has excellent heat insulation performance, and the cable strand sheath 2 wraps the ceramic fiber 3 outside, which can effectively isolate the influence of external factors such as light on the temperature of the internal cable strand 2 of the main cable. Thereby the temperature difference between the inner strands 2 is reduced.

[0017] Make the temperature field distribution of the main cable even, so that the stress distribution between the strands 2 inside the main cable is balanced, and the quality of the main cable is improved.

[0018] The above descriptions are only preferred embodiments of the present invention, and do not limit the present invention in any form. Any simple modifications, equivalent changes and modific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com