Telescopic building platform

A construction platform and workbench technology, which is applied in the direction of construction, building structure, housing structure support, etc., can solve the problems that the construction platform cannot be freely expanded and contracted, and the safety protection is not in place, so as to improve the ability to respond to the environment, ensure personal safety, and ensure The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

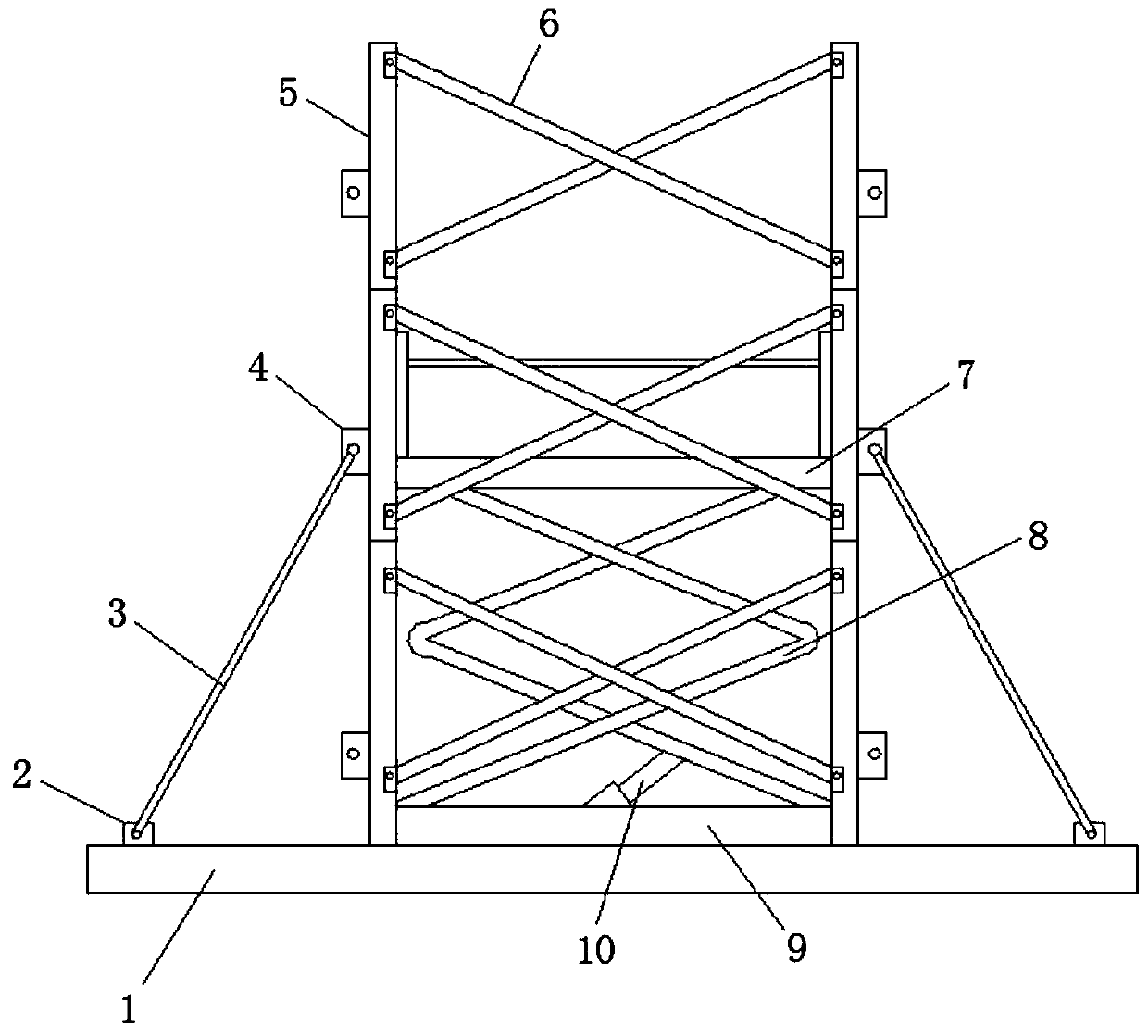

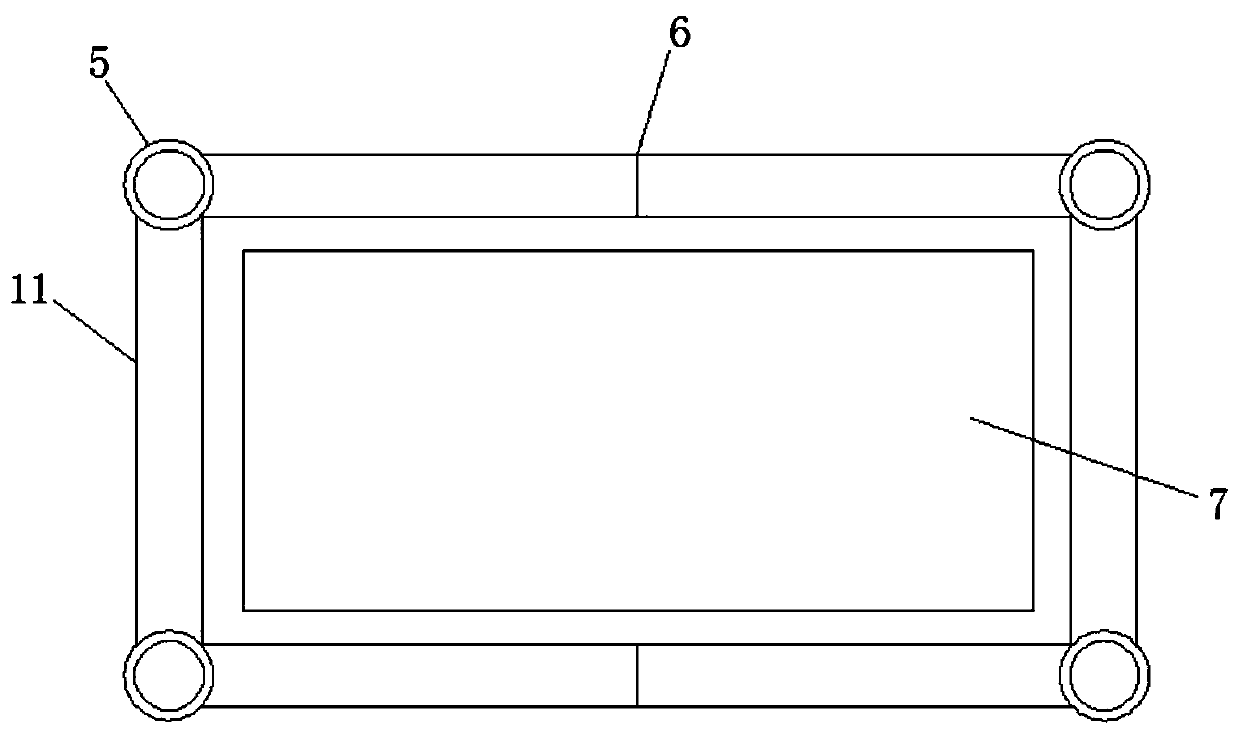

[0030] Example 1, please refer to Figure 1~3 , a retractable building platform, comprising a support base 1, a fixed column 5 is provided in the middle of the support base 1, and locks 4 are respectively provided on the left and right sides of the fixed column 5, and the left and right sides of the support base 1 are The side positions are respectively provided with fixed buckles 2, and the fixed buckles 2 and the lock buckles 4 are directly connected with steel cables 3. The fixed column 5, the fixed rod 11 and the diagonal brace 6 are combined into a frame structure. For fixed connection, a fixed block 12 is provided on the side away from the fixed rod 11 on the fixed column 5, and an empty slot 13 is provided in the fixed block 12, and an embedded column 14 is provided on the diagonal brace 6, and the embedded column 14 is embedded in the empty slot 13, the diagonal brace 6 is detachably fixed on the fixed column 5 through the combination of the embedded column 14 and the ...

Embodiment 2

[0031] Example 2, please refer to Figure 1~4 , a retractable building platform, comprising a support base 1, a fixed column 5 is provided in the middle of the support base 1, and locks 4 are respectively provided on the left and right sides of the fixed column 5, and the left and right sides of the support base 1 are The side positions are respectively provided with fixed buckles 2, and the fixed buckles 2 and the lock buckles 4 are directly connected with steel cables 3. The fixed column 5, the fixed rod 11 and the diagonal brace 6 are combined into a frame structure. For fixed connection, a fixed block 12 is provided on the side away from the fixed rod 11 on the fixed column 5, and an empty slot 13 is provided in the fixed block 12, and an embedded column 14 is provided on the diagonal brace 6, and the embedded column 14 is embedded in the empty slot within 13;

[0032] The diagonal brace 6 is detachably fixed on the fixed column 5 through the combination of the embedded c...

Embodiment 3

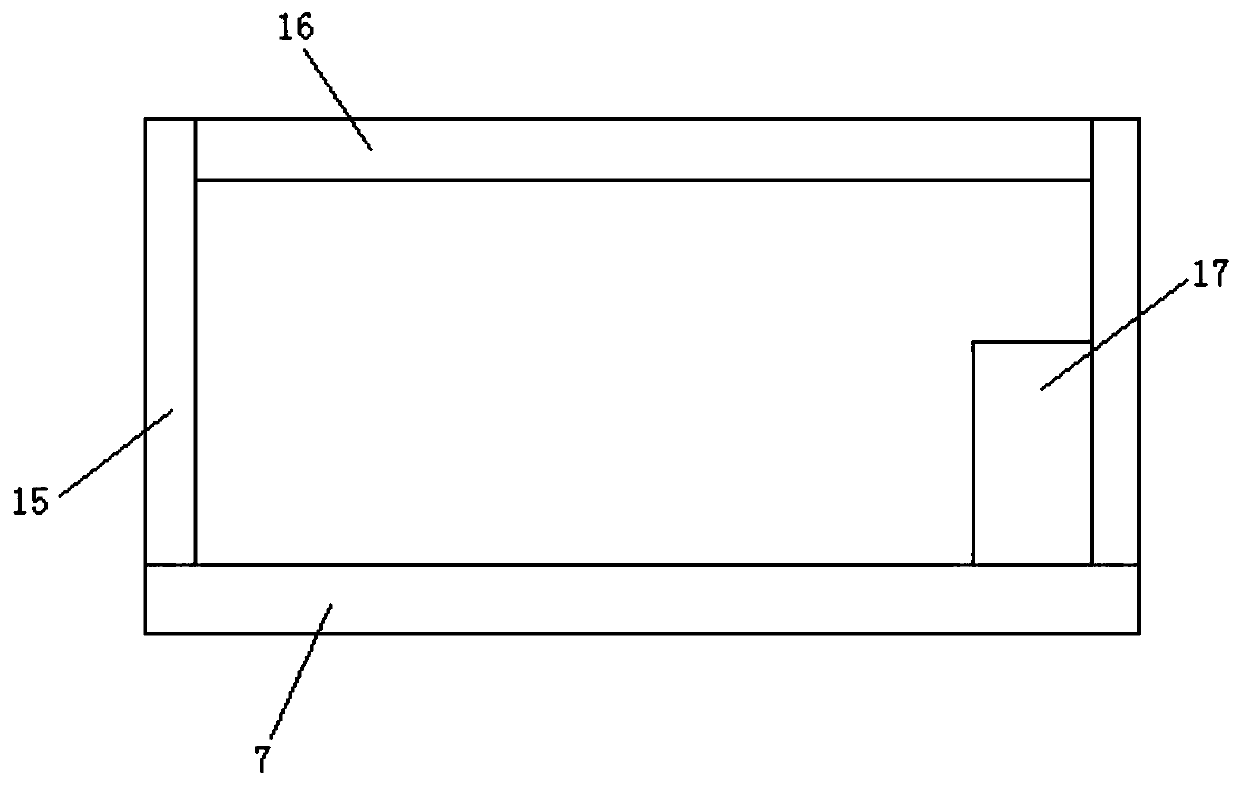

[0034] Embodiment three, please refer to Figure 1~5 , a retractable building platform, comprising a support base 1, a fixed column 5 is provided in the middle of the support base 1, and locks 4 are respectively provided on the left and right sides of the fixed column 5, and the left and right sides of the support base 1 are The side positions are respectively provided with fixed buckles 2, and the fixed buckles 2 and the lock buckles 4 are directly connected with steel cables 3. The fixed column 5, the fixed rod 11 and the diagonal brace 6 are combined into a frame structure. For fixed connection, a fixed block 12 is provided on the side away from the fixed rod 11 on the fixed column 5, and an empty slot 13 is provided in the fixed block 12, and an embedded column 14 is provided on the diagonal brace 6, and the embedded column 14 is embedded in the empty slot 13, the diagonal brace 6 is detachably fixed on the fixed column 5 through the combination of the embedded column 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com