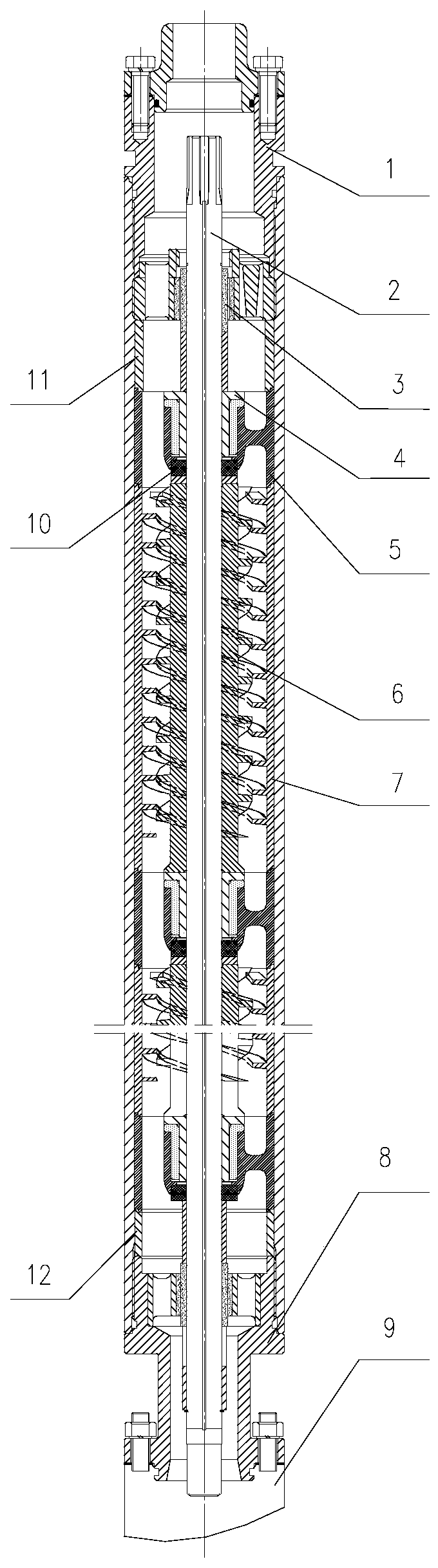

Electric submersible pump for multistage dual-reverse-screw lifting split bearing structure

A double-reversed spiral, load-bearing structure technology, applied in the field of machinery, can solve problems such as low efficiency, unstable operation, and poor fluid transportation performance, and achieve the effects of long service life, small occupied area and space, and high lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

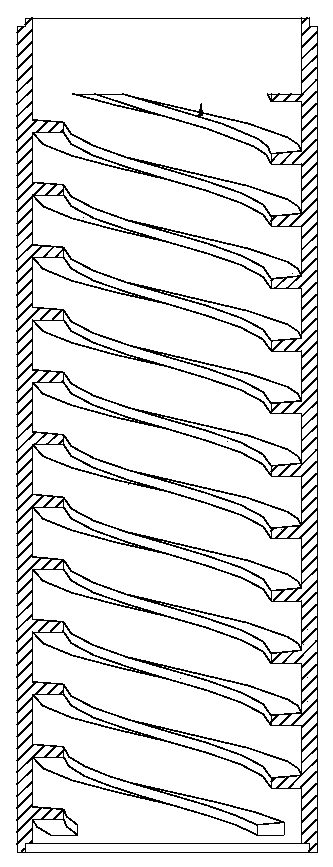

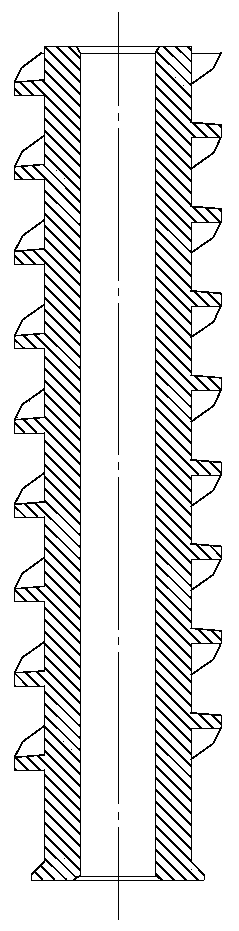

[0018] Depend on Figure 1 to Figure 3 As shown, an electric submersible pump with a multi-stage double-reverse helical lifting split bearing structure includes an upper joint 1, a main shaft 2, and a lower joint 8. The lower part of the upper joint 1 is connected with an upper outer cylinder 11 and a lower joint 8. The upper part is connected with a lower outer cylinder 12, and there are at least two load-bearing centralizers 5 between the upper outer cylinder 11 and the lower outer cylinder 12. The upper outer cylinder 11, the load-bearing centralizer 5, and the lower outer cylinder 12 are provided with jackets. The two ends are respectively threaded on the upper joint 1 and the lower joint 8 . A stator 7 is connected between every two load-bearing centralizers 5, and a rotor 6 is arranged inside the stator 7, and the rotor 6 is connected to the main shaft 2 through a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com