Center rotating joint provided with angle sensor

A central rotary joint and angle sensor technology, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problems of not being able to truly reflect the rotation angle, poor reliability, and reduced flow area, and achieve processing and production Low cost, easy maintenance or replacement, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

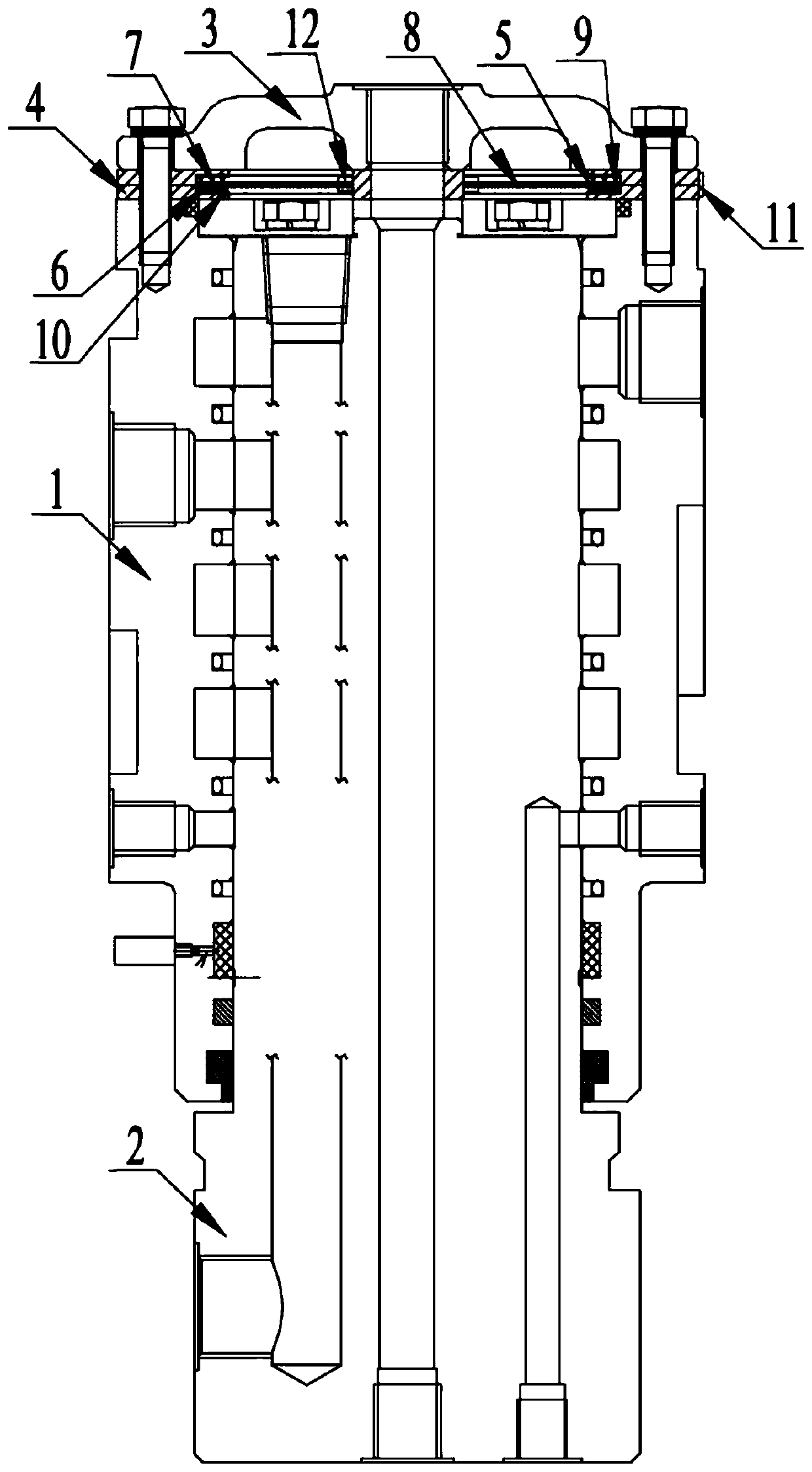

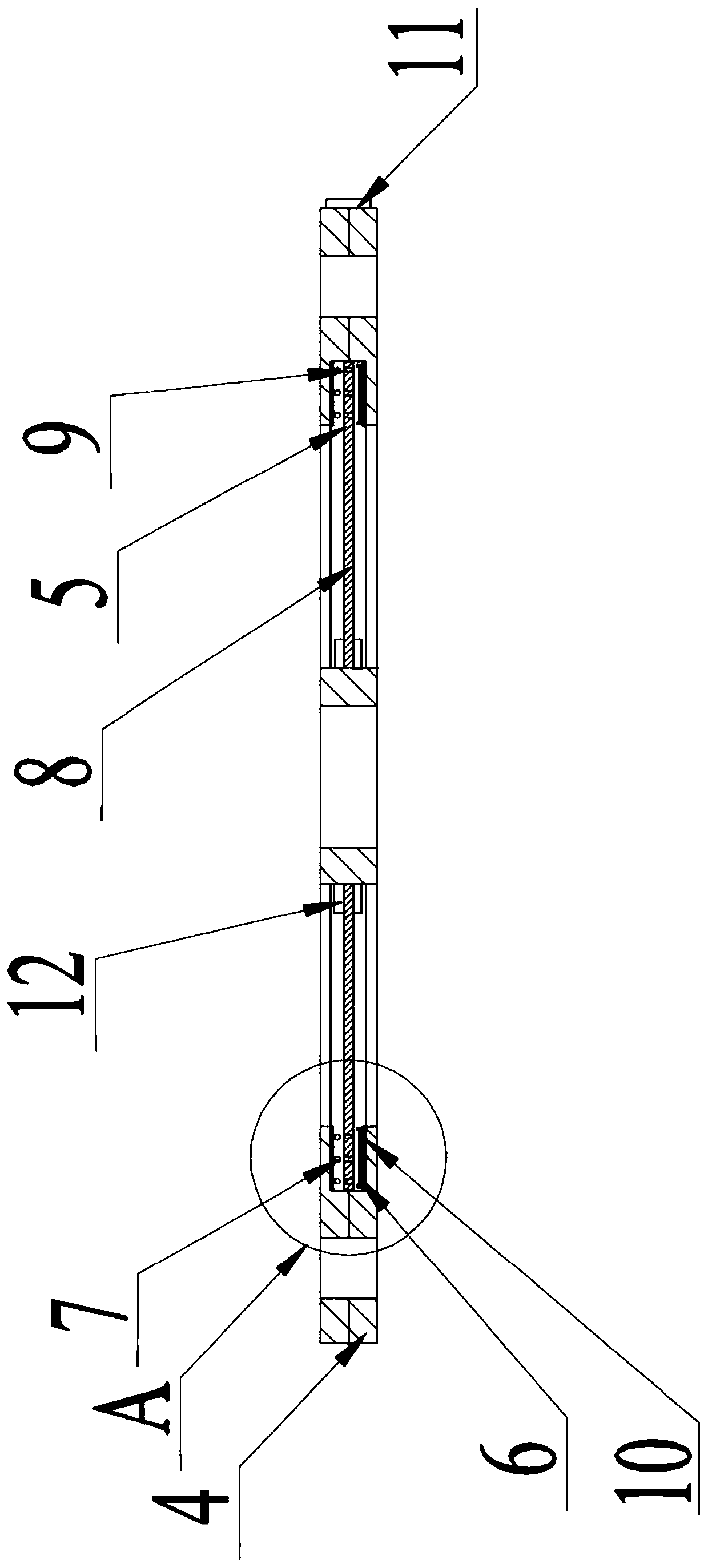

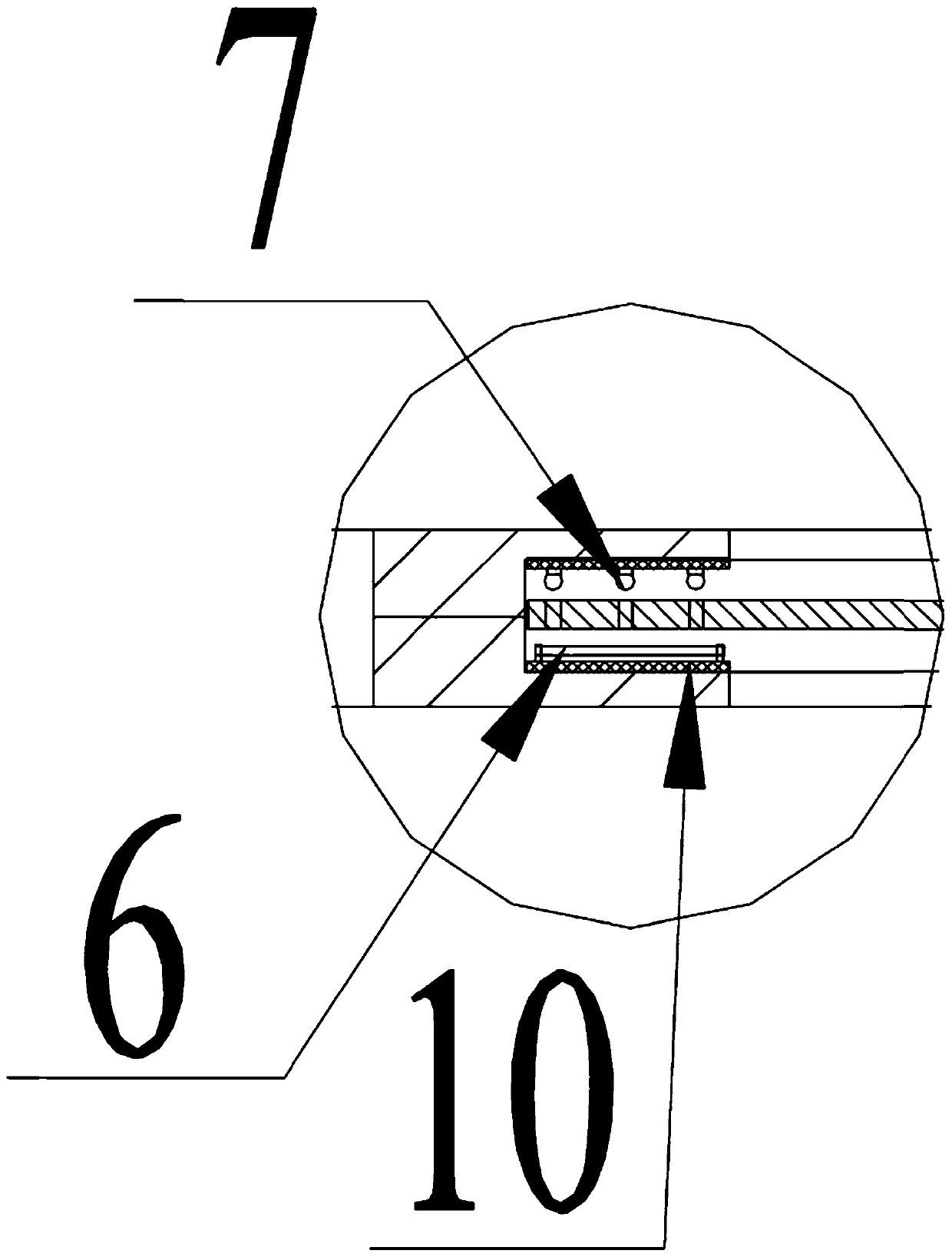

[0030] Such as Figure 1-7 As shown, the present invention is a central rotary joint provided with an angle sensor. The central rotary joint includes a rotary body 1, a rotary shaft 2 and an end cover 3, and an angle sensor is provided at the connection between the rotary body 1 and the end cover 3. The installation ring 4 is provided with an annular groove 5 on the inner ring of the angle sensor installation ring 4, and an angle signal transmitting device 5 and an angle signal receiving device 7 are respectively provided on the two opposite ring surfaces in the annular groove 5, and an angle signal transmitting device 7 is arranged on the angle signal tran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap