Non-contact wide-temperature-difference infrared temperature measurement method

An infrared temperature, non-contact technology, used in radiation pyrometry, measuring devices, optical radiation measurement, etc., can solve the problems of inaccurate measurement accuracy, temperature measurement failure, narrow temperature measurement range, etc., to achieve temperature measurement accuracy High, fast tracking measurement, wide temperature range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

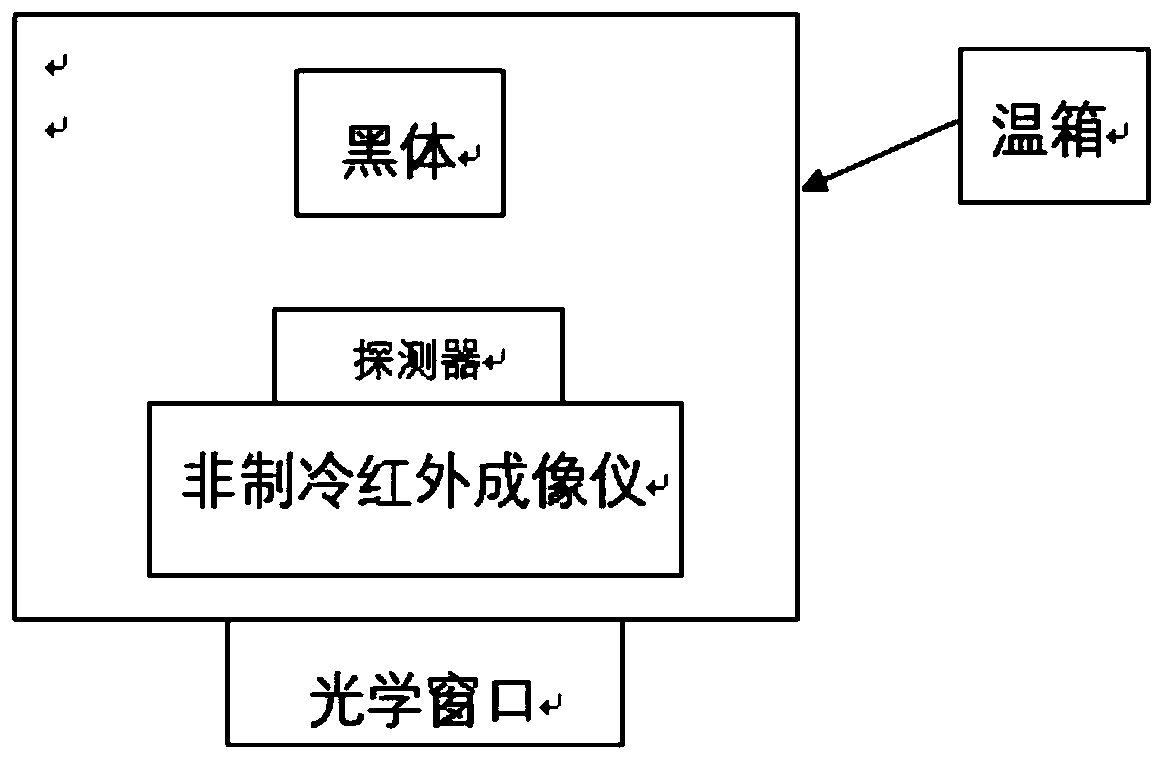

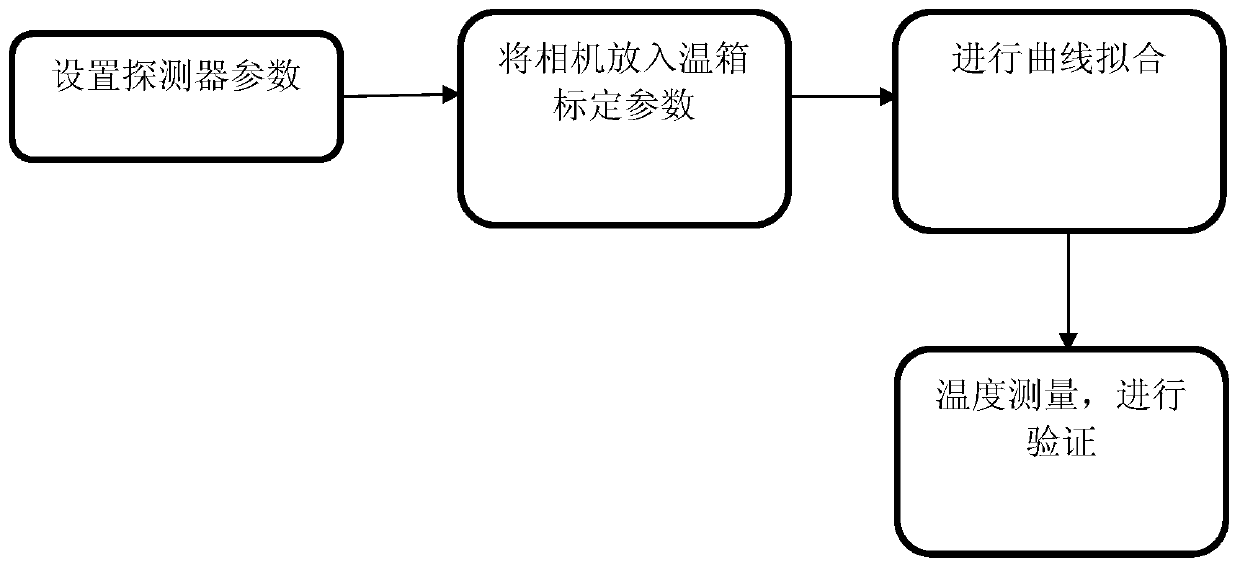

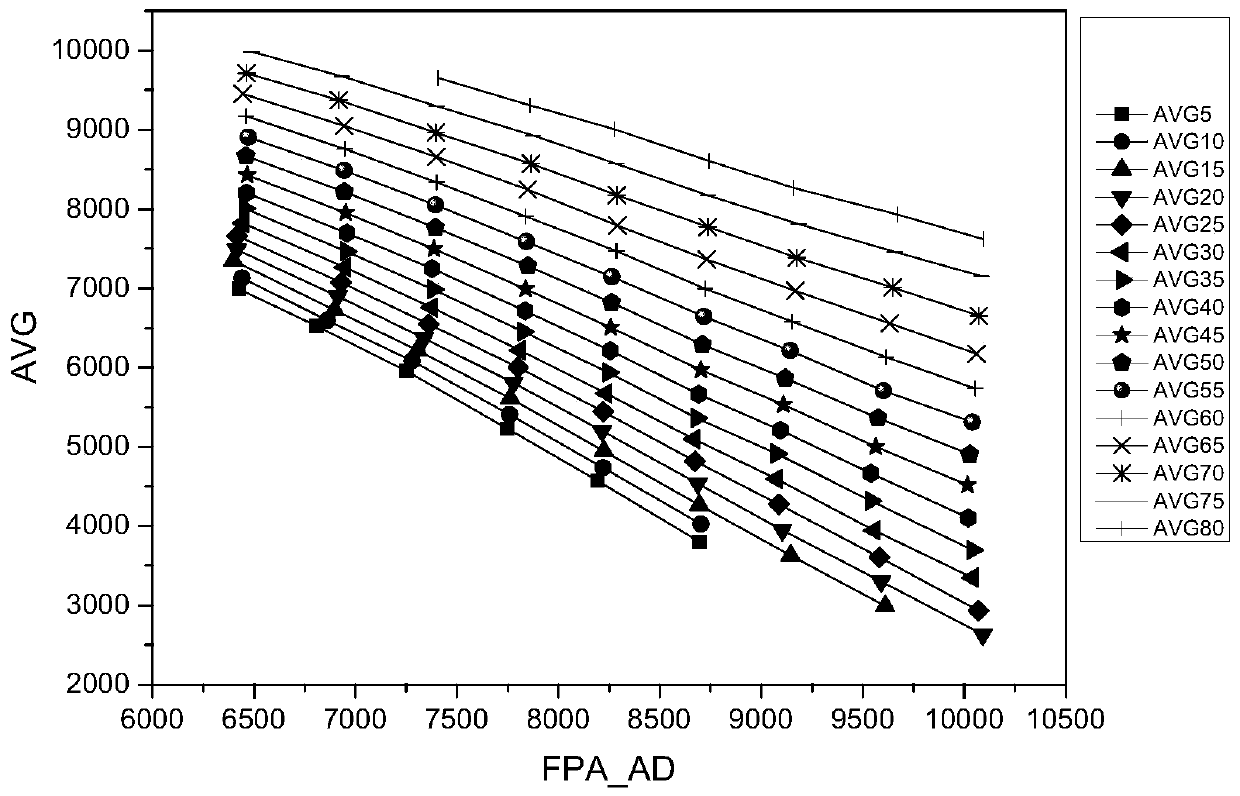

Embodiment 1

[0050] The working environment temperature range of the technical solution of this embodiment is 0°C to 40°C, the temperature measurement range is 5°C to 300°C, and the temperature measurement accuracy is required to be ±2°C (100°C), Due to the wide temperature measurement range, fixing a detector configuration (including integration time length, integration capacitance, GSK setting) will cause the imager to be saturated in the face of a higher temperature scene, and the detector configuration is divided into normal temperature segments according to the temperature measurement range configuration (5°C-80°C), sub-high temperature section configuration (80°C-200°C), and high-temperature section configuration (200°C-300°C). In the normal temperature scene, it is necessary to adjust the parameters of the detector to ensure that the imager has a higher temperature resolution and a better NETD index. In the face of a sub-high temperature scene, the integration time is shortened by se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com