A railway inspection method and system based on computer vision and ultrasonic flaw detection

A technology of computer vision and detection method, which is applied to the shape measuring instrument of railway vehicles, the use of sonic/ultrasonic/infrasonic waves to analyze solids, railway vehicle body parts, etc. , can not guarantee the safe operation of the railway and other problems, to avoid the waste of human and material resources, ensure safe operation, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

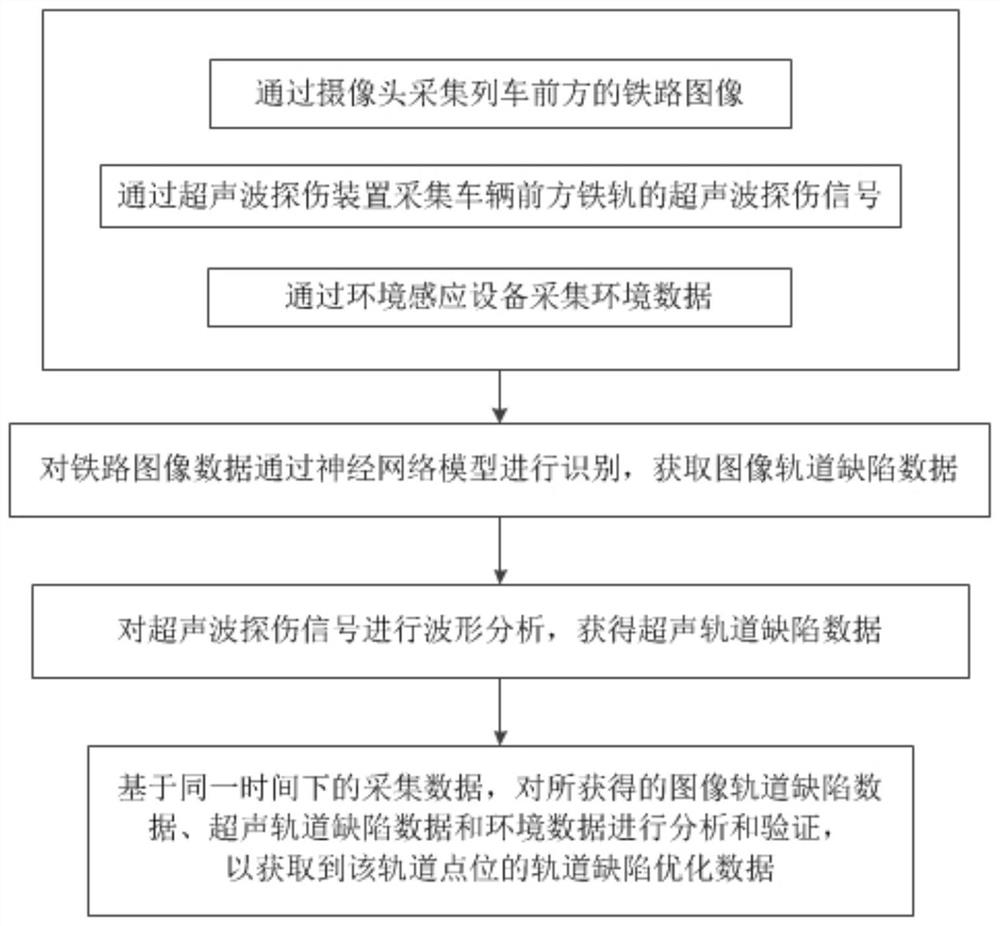

[0044] In this example, see figure 1 As shown, the present invention proposes a railway detection method based on computer vision and ultrasonic flaw detection, comprising steps:

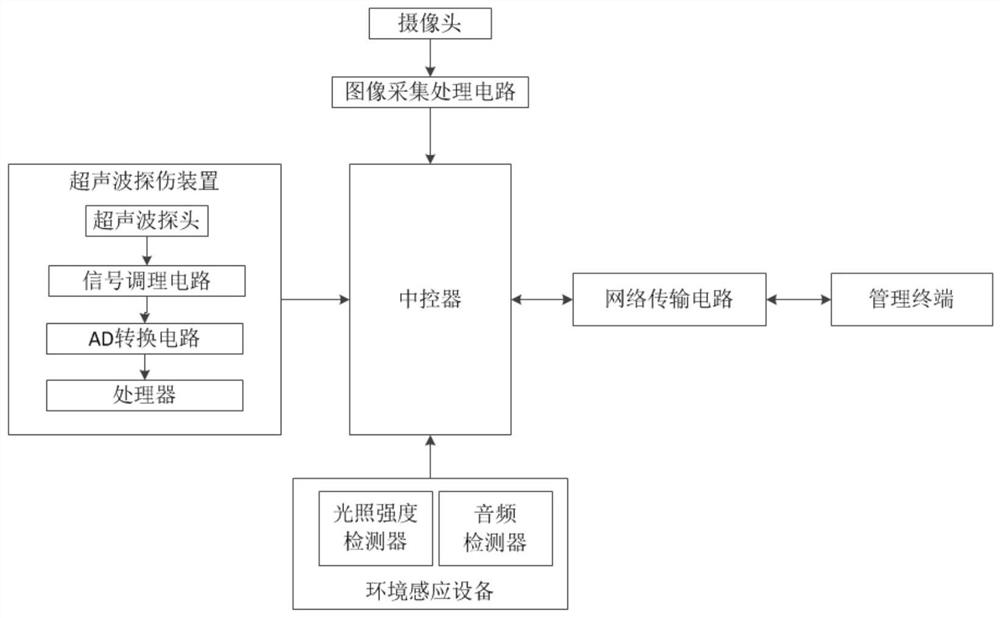

[0045] The railway image in front of the train is collected through the camera, the ultrasonic flaw detection signal of the rail in front of the vehicle is collected through the ultrasonic flaw detection device, and the environmental data is collected through the environmental sensing device; the camera and the ultrasonic flaw detection device are arranged side by side, and the same point information of the track is collected at the same time;

[0046] Identify the railway image data through the neural network model to obtain image track defect data;

[0047] Perform waveform analysis on ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com