Connector pin resistance automatic test equipment

An automatic test equipment and connector technology, applied in the field of aviation equipment, can solve problems such as easy test errors, small pin labels, human errors, etc., and achieve the effects of reducing maintenance costs, reliable and stable operation, and improving measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

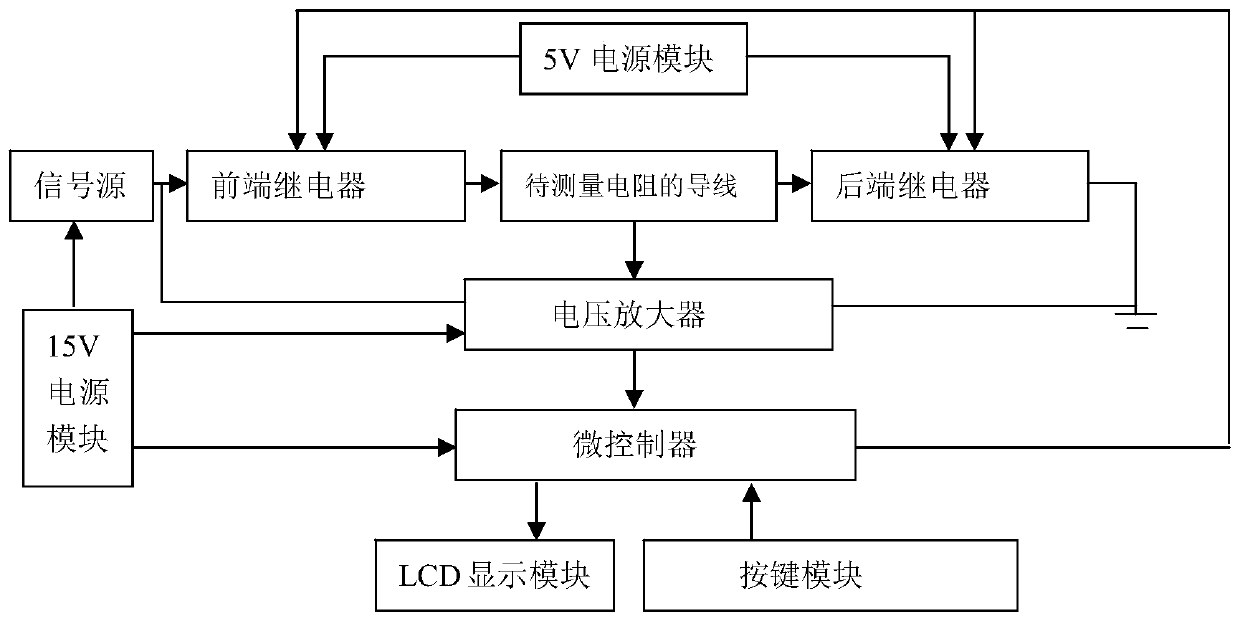

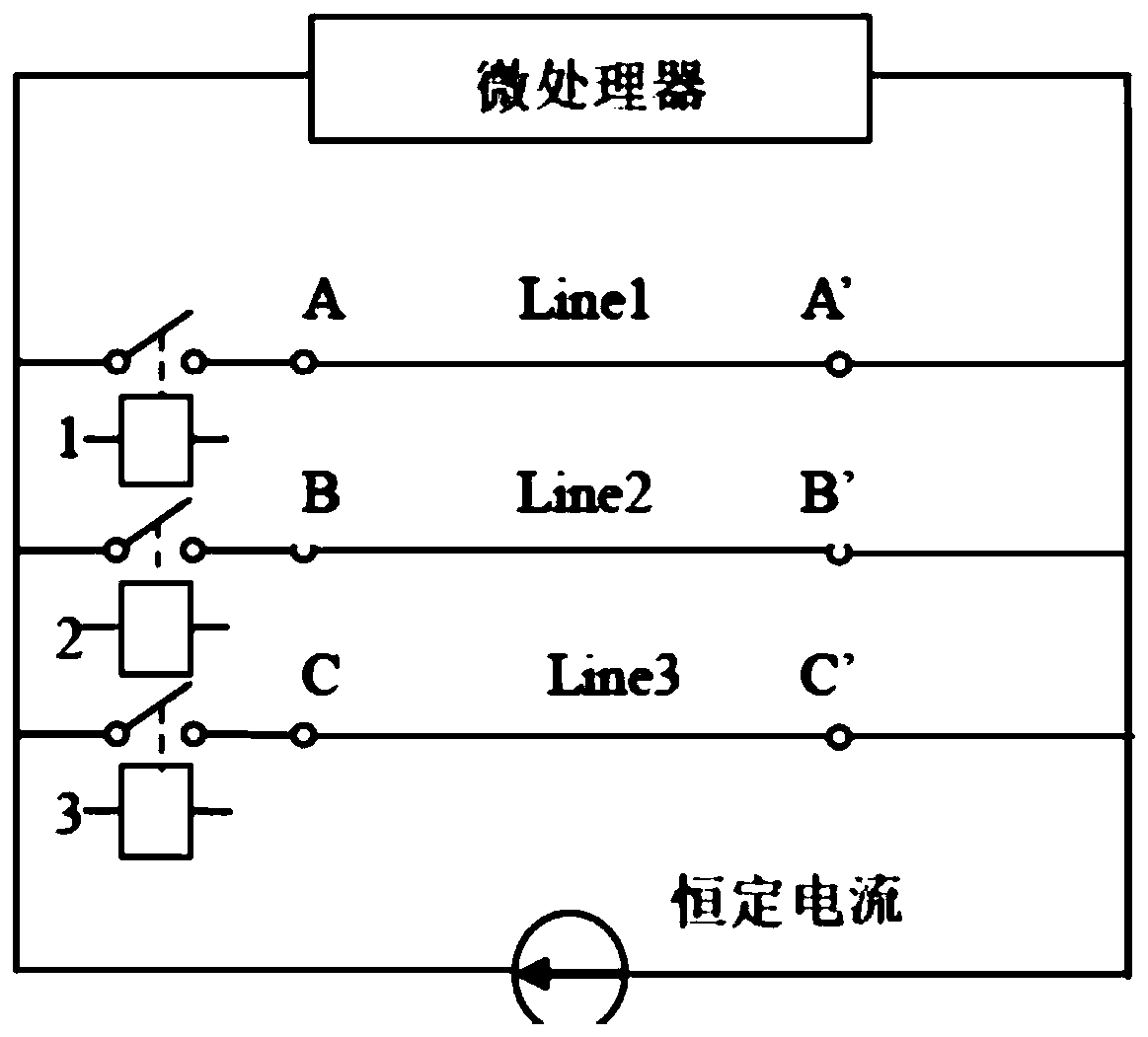

[0034] This embodiment provides a connector pin resistance automatic test equipment, see the attached figure 1 , including: microcontroller, power module, voltage amplifier, signal source, relay, LCD display module and key module;

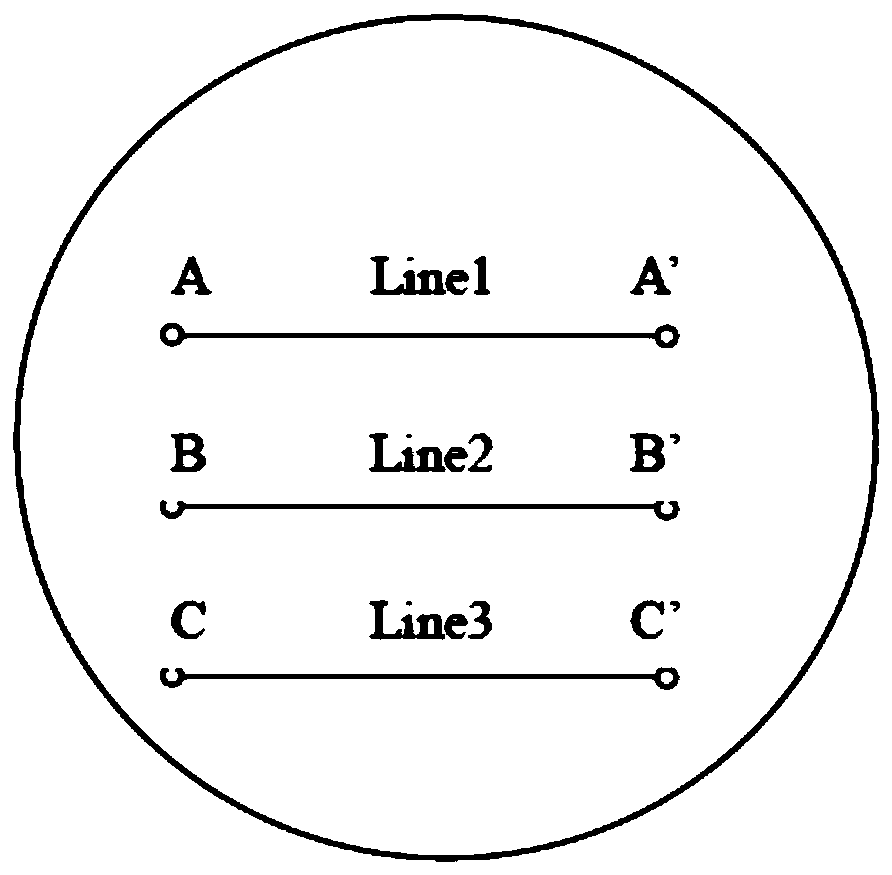

[0035] See attached Figure 5 , the connection relationship of the wires to be tested is as follows: 38 wires are divided into five groups, the first group includes 14 wires, and the 14 wires are connected end to end to form 2 endpoints and 13 intermediate points, so that the 2 endpoints are respectively A1 and A15, the order of 13 intermediate points is A2, A3, A4, A5, A6, A7, A8, A9, A10, A11, A12, A13, A14; the second group, the third group, and the fourth group are the same, all Including 3 wires, 3 connected end to end, forming 2 endpoints and 2 intermediate points in total, so that the 2 endpoints are respectively B1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com