Continuum structure topology and shape dimension comprehensive optimization method

An optimization method and continuum technology, applied in design optimization/simulation, geometric CAD, etc., can solve problems that affect optimization results and cannot describe the internal evolution process of structures favorably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

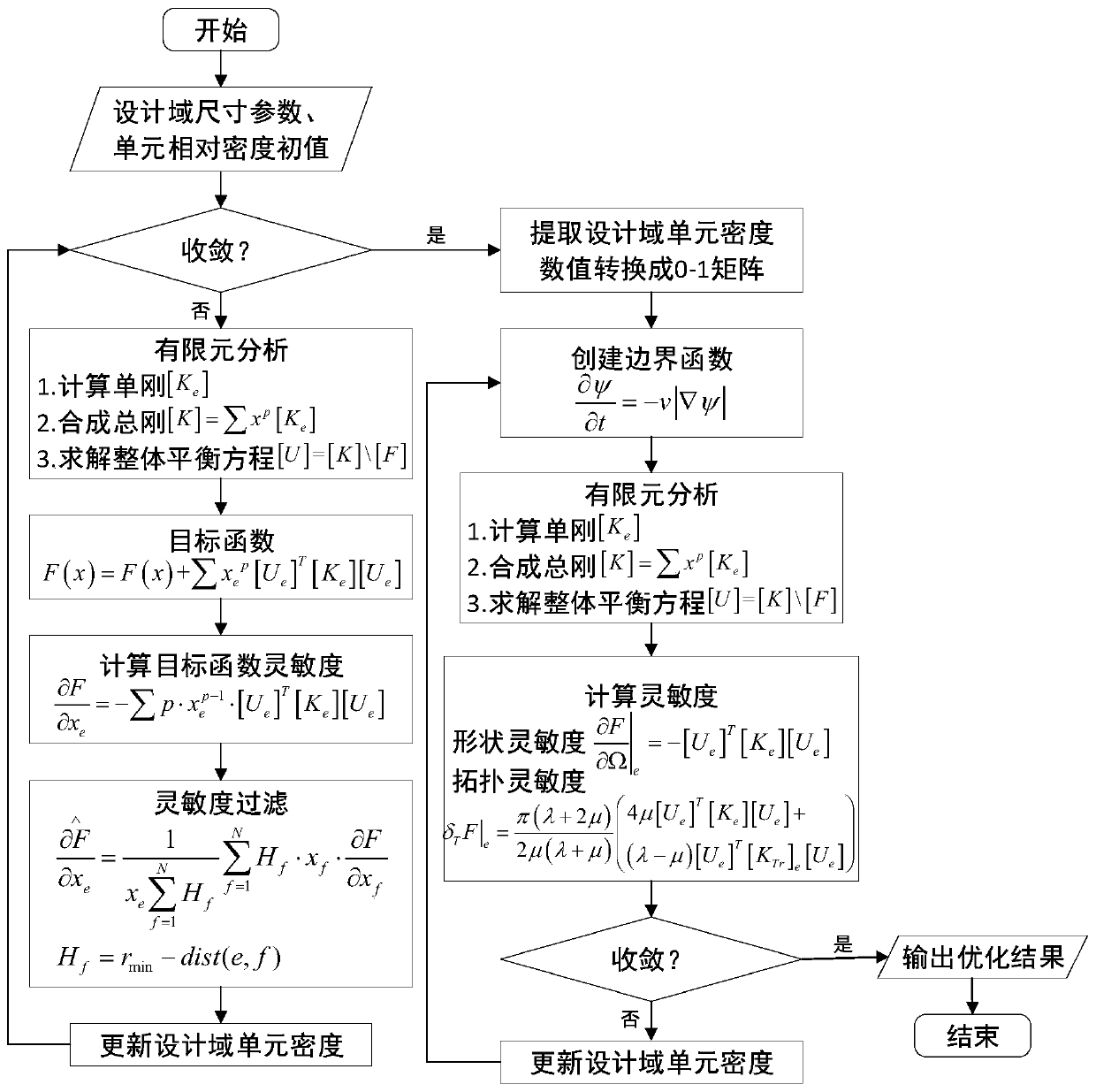

Method used

Image

Examples

Embodiment 1

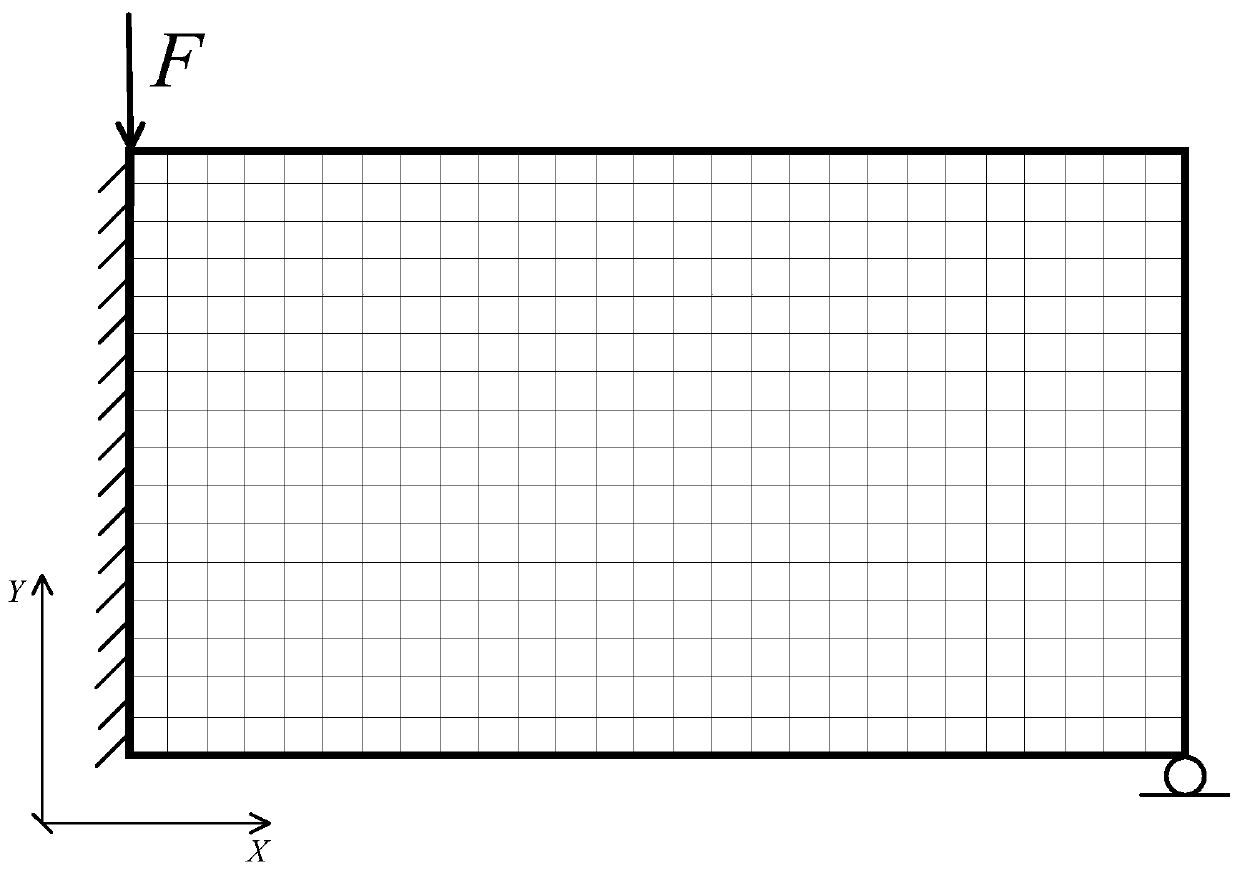

[0055] In this embodiment, the description of the optimal design process is carried out with a two-dimensional rectangular design domain as the object. It is set, but not limited to, that the Young's modulus E of the material is equal to 1 MPa, the Poisson's ratio μ is equal to 0.3, the length of the design domain is 60 mm, and the height is 30 mm.

[0056] In this example, if figure 2 As shown, according to step S1 to step S3, the rectangular design domain is divided into finite element meshes to obtain unit node information, and the left side of the rectangular design domain is fixedly connected to limit the degrees of freedom in all directions. In the lower right corner of the rectangular design domain Limit the movement in the Y direction, and impose a load constraint F equal to 1kN along the negative Y direction at the upper left corner of the rectangular design domain.

[0057] In this embodiment, according to steps S2 to S5, structural topology optimization is perform...

Embodiment 2

[0061] In this embodiment, the initial design conditions of Embodiment 1 are used as the optimization object, but the position and form of constraints and loads imposed on the design domain are changed, such as Image 6 shown. According to steps S1 to S3, the rectangular design domain is divided into finite element meshes to obtain unit node information, and the lower left corner of the rectangular design domain is fixedly connected to limit the degrees of freedom in all directions, and the lower right corner of the rectangular design domain is slid Connect to limit the degree of freedom in the Y direction, and impose a load constraint F equal to 1kN along the negative Y direction at the middle of the bottom edge of the rectangular design domain.

[0062] In this embodiment, according to steps S2 to S5, structural topology optimization is performed on the design domain to obtain a topological configuration with gray-scale units and internal holes, such as Figure 7 shown. Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com