High-temperature superconductor high-voltage transformer for serving as low current high-voltage power and application thereof

A high-voltage transformer and high-temperature superconducting technology is applied in the field of transformers to achieve the effects of reducing internal friction, increasing conduction current density, and increasing conduction current density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

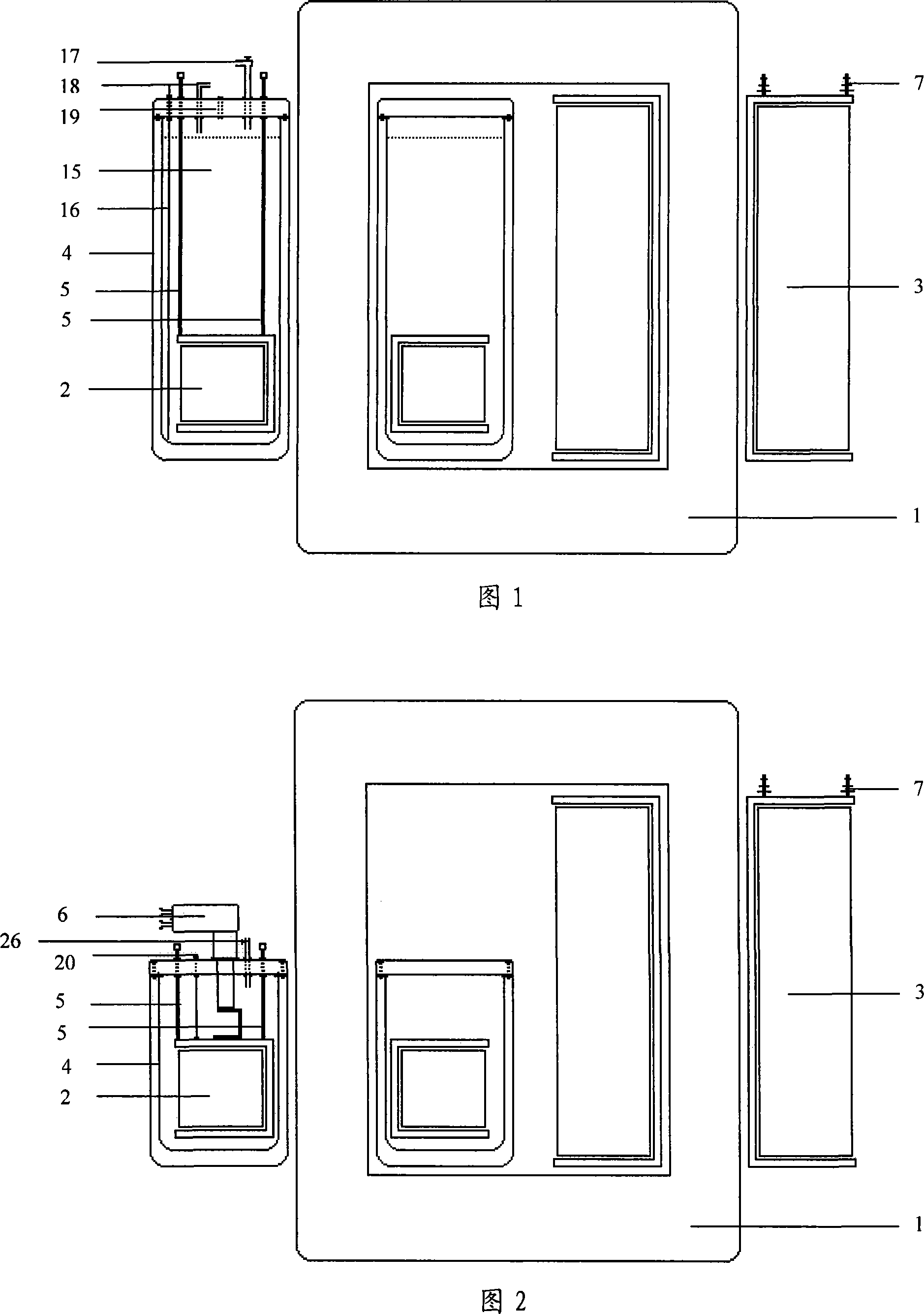

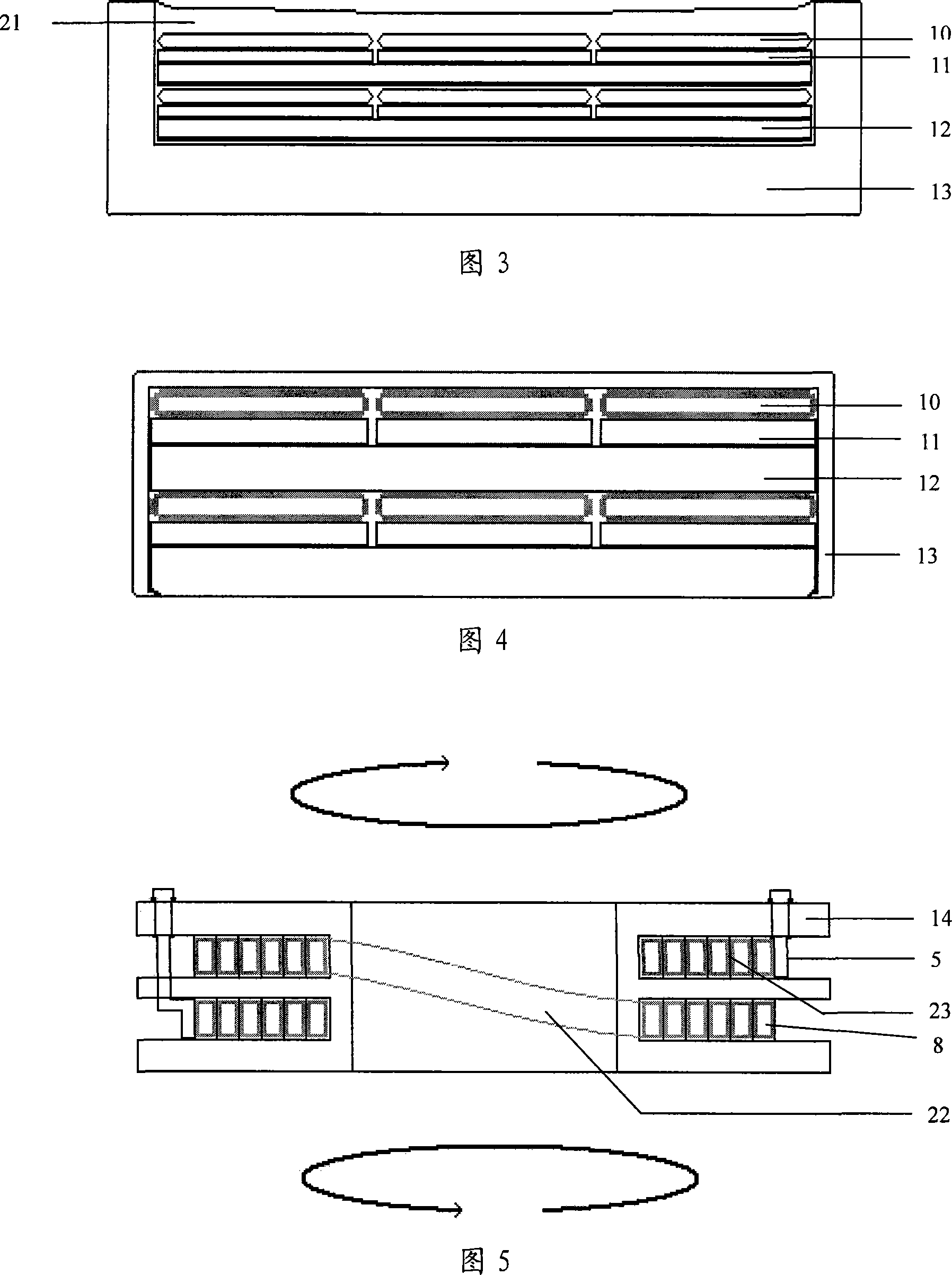

[0042] As shown in Figure 1, Figure 3, Figure 5, and Figure 7. A high temperature superconducting high voltage transformer power supply of 100000V / 0.5A / 50Hz is prepared. The high-temperature superconducting high-voltage transformer includes an iron core 1, a primary coil 2 and a secondary coil 3, the primary coil 2 is connected to an external power supply through a high-current lead 5, and the secondary coil 3 outputs high-voltage electricity through a high-voltage output port 7; the primary coil 2 is wound by composite high-temperature superconducting wire 8, which is a high-current low-resistance loss coil. The secondary coil 3 is wound by traditional high-voltage coil technology; The specific data of the high-temperature superconducting high-voltage transformer is as follows, which constitutes a practical high-voltage transformer with single-phase low primary power supply voltage.

[0043] The design parameters of the high-temperature superconducting high-voltage transform...

Embodiment 2

[0056]As shown in Figure 2, Figure 4, Figure 6, and Figure 8. A 500000V / 0.1A / 50Hz high-temperature superconducting high-voltage transformer power supply is prepared. The high-temperature superconducting high-voltage transformer includes an iron core 1, a primary coil 2 and a secondary coil 3, the primary coil 2 is connected to an external power supply through a high-current lead 5, and the secondary coil 3 outputs high-voltage electricity through a high-voltage output port 7; the primary coil 2 is wound by a composite high-temperature superconducting wire 8, which is a high-current low-resistance loss coil. The secondary coil 3 is wound by traditional high-voltage coil technology; the primary coil 2 is placed in a low-temperature container 4 and cooled by a refrigerator 6 . The specific data of the high-temperature superconducting high-voltage transformer is as follows, constituting a single-phase practical high-voltage transformer.

[0057] The design parameters of the high-...

Embodiment 3

[0070] The same places as in Embodiment 1 will not be repeated, the difference is that the iron core 1 is an amorphous alloy.

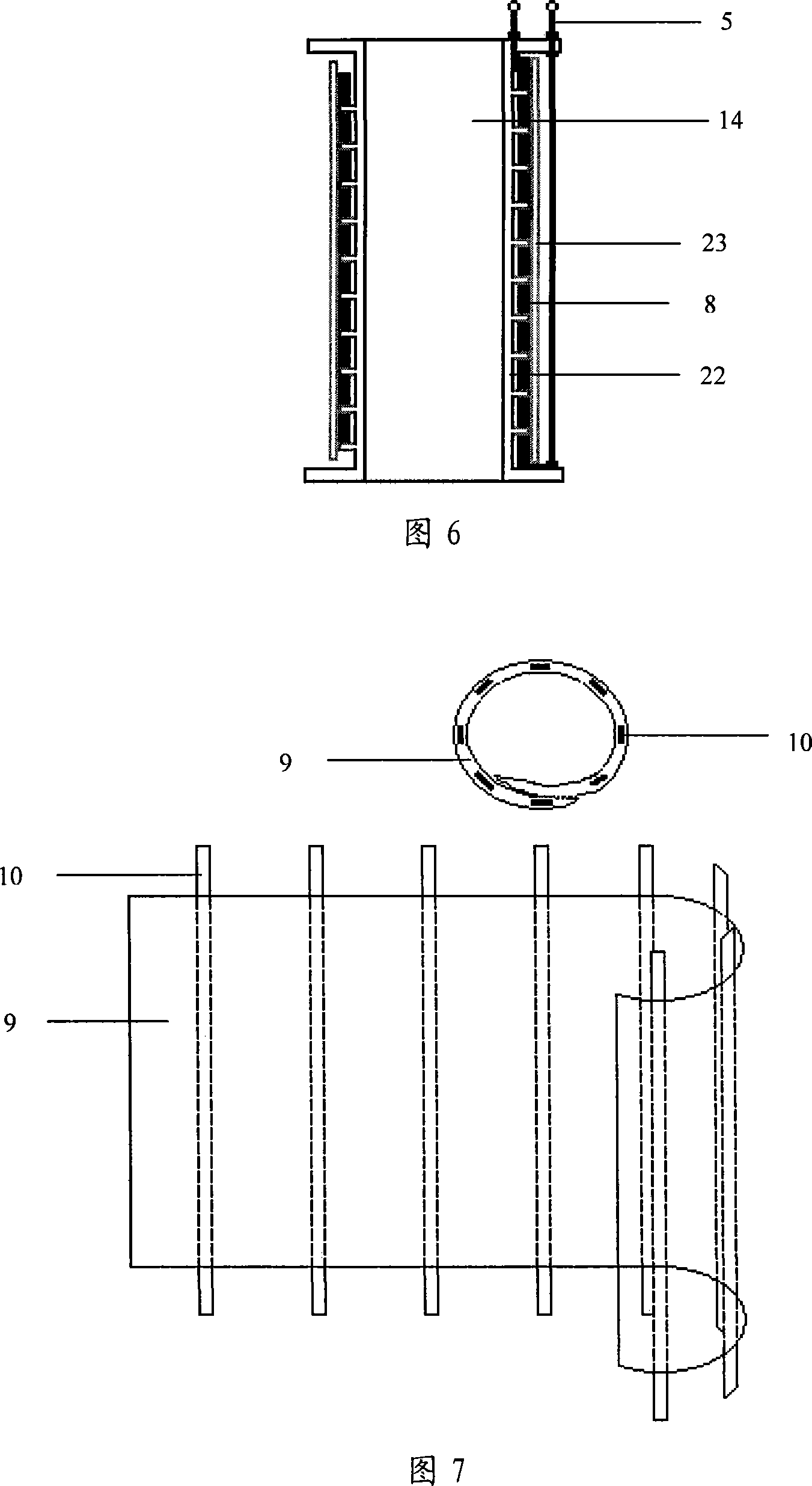

[0071] The primary coil 2 is wound by a high temperature superconducting initial strip 10 . The high temperature superconducting initial tape 10 is (Bi, Pb) 2 Sr 2 Ca 2 Cu 3 o 10+x Single core high temperature superconducting wire. The primary coil 2 is a single-cake coil prepared by using the above-mentioned high-temperature superconducting initial strip 10 . The high-current lead wire 5 is prepared by wrapping and winding the composite high-temperature superconducting wire 8 prepared by the filling, sealing, potting and strengthening process by using glass fiber tape as the insulating tape 9 . The primary coil 2 is placed in a non-vacuum non-metal cryogenic cylinder with a built-in foam material insulation layer as a cryogenic container 4 and a reinforced shell outside, and works in 87K liquid argon as a refrigerant 15 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com