MEMS process-based high-Q value three-dimensional spiral structure inductor and fabrication method thereof

A helical structure and manufacturing method technology, applied in the field of microelectronics, can solve the problems of inconvenient IC compatible integration, insufficient mechanical stability, and difficulty in subsequent packaging, and achieve the effects of cost control, high Q value, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

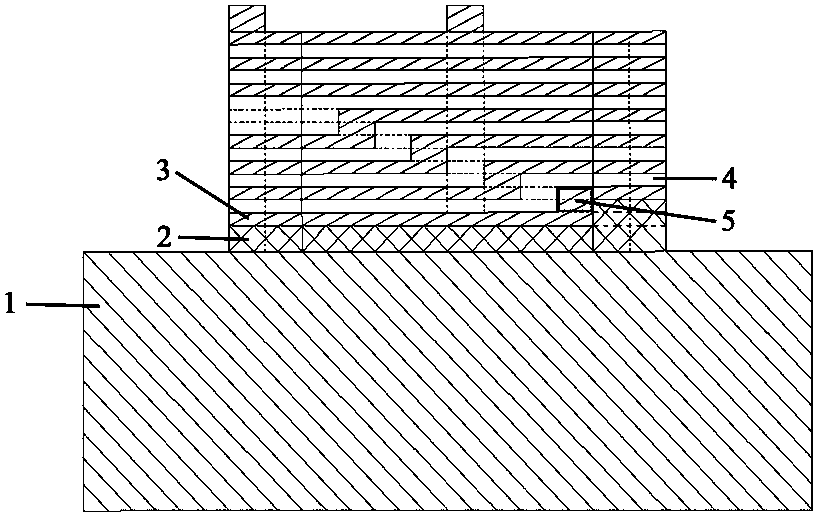

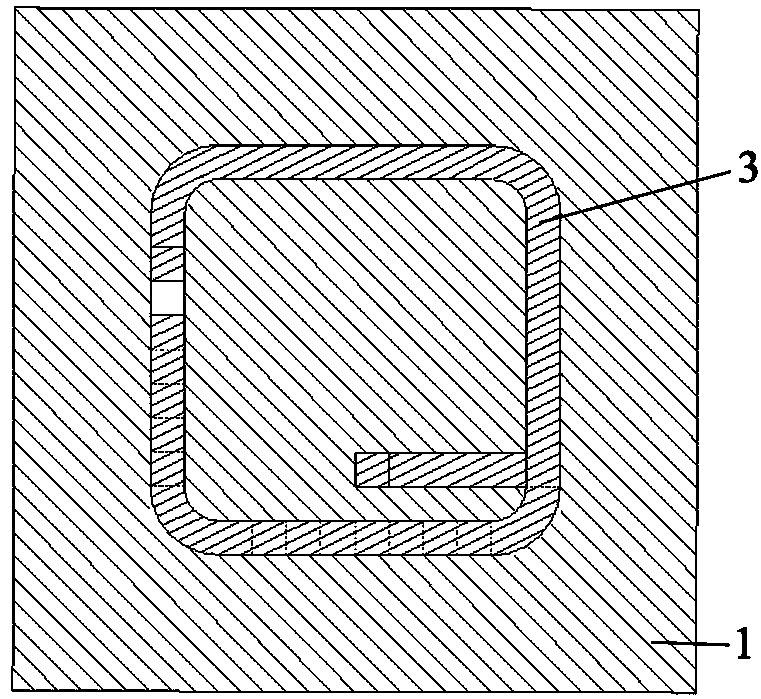

[0043] exist figure 1 It is a high-Q eight-layer spiral structure integrated inductor structure based on MEMS technology, figure 2 It is a top view of the inductor, in which the input and output terminals of the inductor are on the same plane, which is convenient for later inductor testing and packaging.

[0044] Before the photolithography process, the mask plate is designed, which is a relatively high part of the process cost. Considering that the vertical solenoid inductor with multilayer coils has a certain geometric repeatability, taking the designed 8-layer vertical solenoid inductor as an example, the mask pattern required for 5 to 8 layer coils is the same as that required for 1 to 4 The patterns of the layers corresponding to the process are almost identical, and it can be used for the 5 to 8 layer coil process only by rotating the 1 to 4 layer mask 90 degrees clockwise. Therefore, when designing the mask, the mask patterns corresponding to each structure are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com