Novel thermistor preparation process

A thermistor and preparation technology, which is applied to thermistors, resistors with negative temperature coefficients, resistors with positive temperature coefficients, etc., can solve the problem of low qualified rate of plate damage, increased cost, and low efficiency and other issues, to achieve the effect of improving the pass rate, saving cost and waste, and making the process simple and orderly

Inactive Publication Date: 2020-04-17

BRAIN POWER (QING YUAN) CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the thermistor is opaque due to the particularity of the material (the color of the material is black), and the material is brittle and easy to break. The production of the tra

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

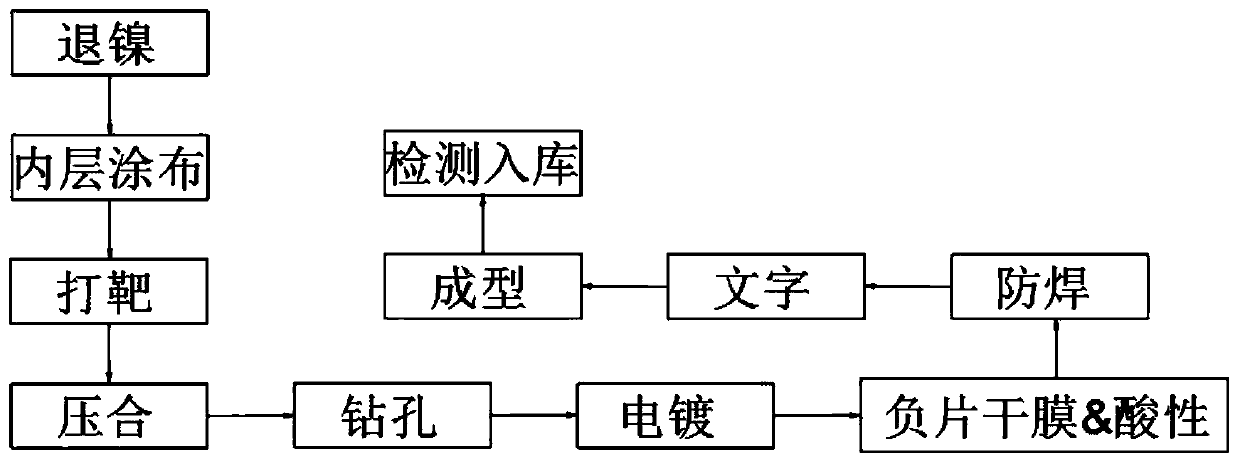

Login to View More Abstract

The invention relates to the technical field of thermistor preparation proces, particularly discloses a novel thermistor preparation process, and solves the problems that the traditional process cannot be qualified and the percent of pass is low due to the fact that the plate is fragile. The novel thermistor preparation process comprises the following procedures of nickel stripping, inner layer coating, targeting, press fitting, drilling, electroplating, negative dry film & acidity, solder mask, text, forming and detection warehousing. The technological process is simple and orderly, and the targeting process is advanced before the press fitting process; meanwhile, a trial drilling hole is formed, the rotating speed of the drilling equipment and the parameters of feeding and retracting canbe adjusted through the test of the trial drilling hole, drilling can be conducted conveniently and orderly, the problem that the whole plate is damaged due to the parameter problem in the drilling process is avoided, the percent of pass of drilling is increased, cost waste is reduced, a copper layer is plated at the drilling position in a chemical copper plating mode, the strength of the drilling position can be improved, and the problems that materials are brittle and liable to be broken during hot melting and riveting are solved.

Description

technical field [0001] The invention relates to the technical field of thermistor preparation technology, in particular to a novel thermistor preparation technology. Background technique [0002] Domestic electronic products are gradually becoming larger, and various products are changing. With the advent of the 5G era, the demand for electronic components is greater and the quality control is stricter, such as thermistors. [0003] However, the thermistor is opaque due to the particularity of the material (the color of the material is black), and the material is brittle and easy to break. The production of the traditional process is prone to the problem of low pass rate of plate damage due to material problems, not only low efficiency, but also due to Too many defective products lead to increased costs. Therefore, those skilled in the art provide a novel manufacturing process of a thermistor to solve the problems raised in the above-mentioned background technology. Conte...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01C7/02H01C7/04

CPCH01C7/008

Inventor 黄蝉陈洁亮廖强

Owner BRAIN POWER (QING YUAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com