Treatment device for precipitating solid fine particles in wastewater

A treatment device and fine-grained technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems that natural sedimentation cannot remove suspended solids and colloids, there is no classification of temporary storage of wastewater, and it affects the treatment process, etc., to achieve good wastewater treatment effect , Improve the quality and effect, the effect of simple and orderly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

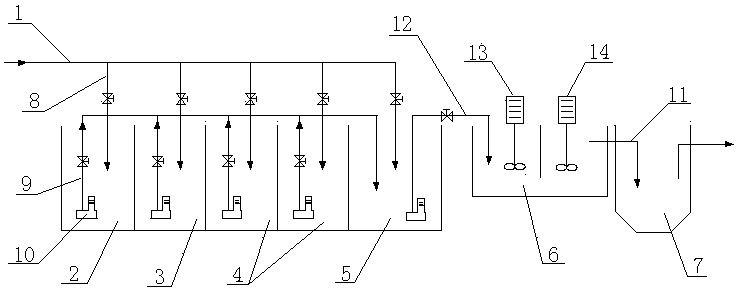

[0021] Such as figure 1 As shown, the present embodiment includes a main water inlet pipe 1, an acid-base pool 2, a hazardous chemical pool 3, at least one collection pool 4, a blending pool 5, a coagulation pool 6, a settling pool 7 and a dosing device, the acid-base pool 2, The hazardous chemical pool 3 and the collection pool 4 are respectively communicated with the deployment pool 5 through the shunt outlet pipe 9, and the acid-base pool 2, the hazardous chemical pool 3, and the collection pool 4 are respectively connected with the main water inlet pipe 1 through the shunt inlet pipe 8, and each shunt Valves are provided on the inlet pipe 8 .

[0022] The bottoms of the acid-base pool 2, the hazardous chemical pool 3 and the collection pool 4 of the present embodiment are respectively provided with a water pump 10, and the water pump 10 is communicated with the shunt outlet pipe 10, and the blending pool 5 and the coagulation pool 6 are communicated through an outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com