Coal slime detection and dosing device for concentration tank

A technology of a dosing device and a concentration tank, which is applied in chemical instruments and methods, separation methods, precipitation and separation, etc., can solve the problems of inability to guide the automatic addition of drugs in the concentration tank, production accidents of pressure rakes, and low timeliness, and achieve a perfect cycle. Water purification system, reduced labor intensity, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

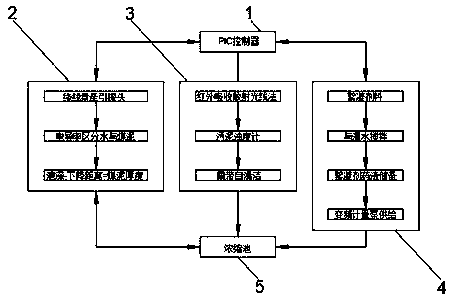

[0021] like Figure 1-2 As shown, the present invention provides a thickening pool slime detection and dosing device, including a PLC controller 1 and a thickening pool 5, the PLC controller 1 is electrically connected to a slime detection mechanism 2, and the PLC controller 1 is electrically connected to a The turbidity detection mechanism 3 and the PLC controller 1 are electrically connected to the automatic dosing mechanism 4 , and the coal slime detection mechanism 2 , the turbidity detection mechanism 3 and the automatic dosing mechanism 4 all extend into the inside of the concentration tank 5 .

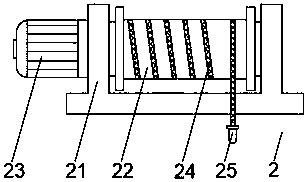

[0022] Coal slime detection mechanism 2 comprises winding frame 21, and winding frame 21 interior rotation is connected with winding roller 22, and one side of winding frame 21 is fixedly installed with stepping motor 23, and stepping motor 23 runs through winding frame 21 and is connected with The winding roller 22 is fixedly connected, and the outside of the winding roller 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com