Fe-based catalyst modified by nitrogen-carbon doping and its preparation method and application

A catalyst, nitrogen-carbon technology, applied in the direction of catalyst activation/preparation, carbon compound catalyst, catalyst, etc., can solve the problems of easy sintering of active components, environmental pollution of Cr-based catalysts, expensive precious metal catalysts, etc., and achieve good catalyst stability , good propane anaerobic dehydrogenation activity, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

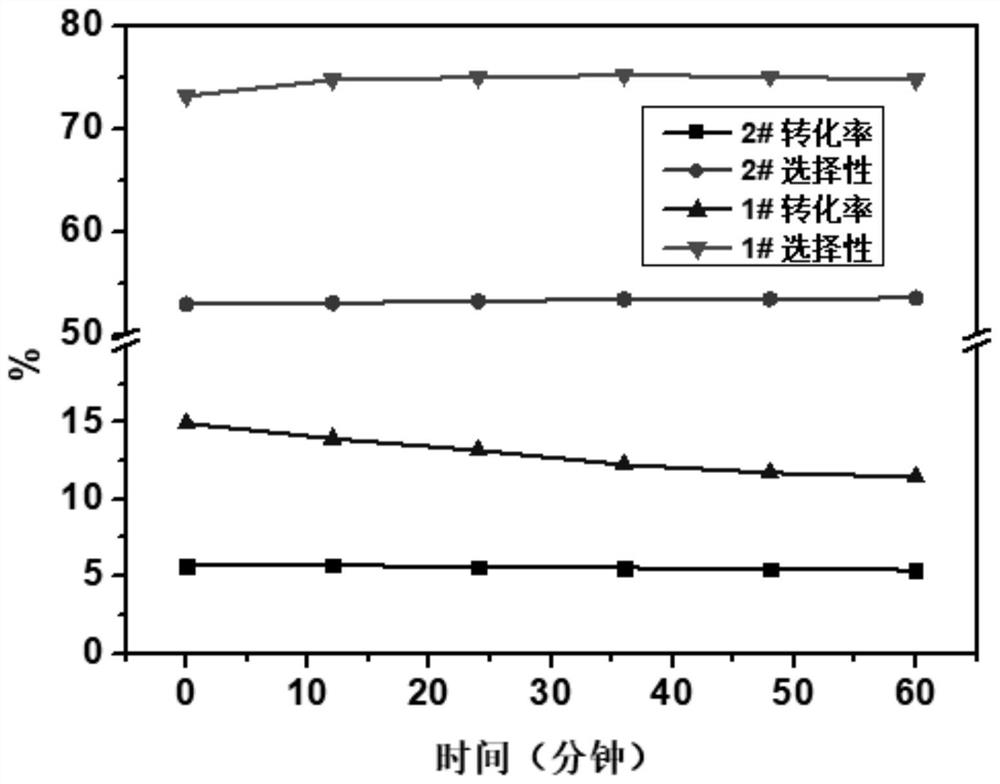

Embodiment 1

[0058] This embodiment provides a nitrogen-carbon doped modified iron-based catalyst, which is prepared by the following steps:

[0059] (1) At room temperature, weigh 3.0g SiO 2 The carrier was dispersed in 100mL of ethylenediamine, stirred and ultrasonicated to obtain a homogeneous mixture I;

[0060] (2) Weigh 4.0 g of dicyandiamide and 0.386 g of iron acetylacetonate into the mixture I, continue ultrasonication and stirring for 10 h at 25°C to fully dissolve and disperse it, and obtain the mixture II;

[0061] (3) The mixture II was rotary evaporated at 80°C, and the obtained product was vacuum-dried at 100°C overnight;

[0062] (4) Place the vacuum-dried product in a tube furnace, and in an Ar atmosphere, raise the temperature to 350°C at a rate of 5°C / min and keep it for 3h, and then rise to 650°C at a rate of 5°C / min And keep it for 2h, continue to raise the temperature to 750℃ at a rate of 5℃ / min and keep it for 2h, and get the nitrogen-carbon doped modified iron-bas...

Embodiment 2

[0085] This embodiment provides a nitrogen-carbon doped modified iron-based catalyst, which is prepared by the following steps:

[0086] (1) At room temperature, weigh 3.0 g of the molecular sieve Silicalite-1 carrier and disperse it in 100 mL of ethylenediamine, stir and sonicate to obtain a homogeneous mixture I;

[0087] (2) Weigh 4.0 g of dicyandiamide and 0.386 g of iron acetylacetonate into the mixture I, continue ultrasonication and stirring for 10 h at 25°C to fully dissolve and disperse it, and obtain the mixture II;

[0088] (3) The mixture II was rotary evaporated at 80°C, and the obtained product was vacuum-dried at 100°C overnight;

[0089] (4) Place the vacuum-dried product in a tube furnace, and in an Ar atmosphere, raise the temperature to 350°C at a rate of 5°C / min and keep it for 3h, and then rise to 650°C at a rate of 5°C / min And keep it for 2h, continue to raise the temperature to 750°C at a rate of 5°C / min and keep it for 2h, to obtain a nitrogen-carbon d...

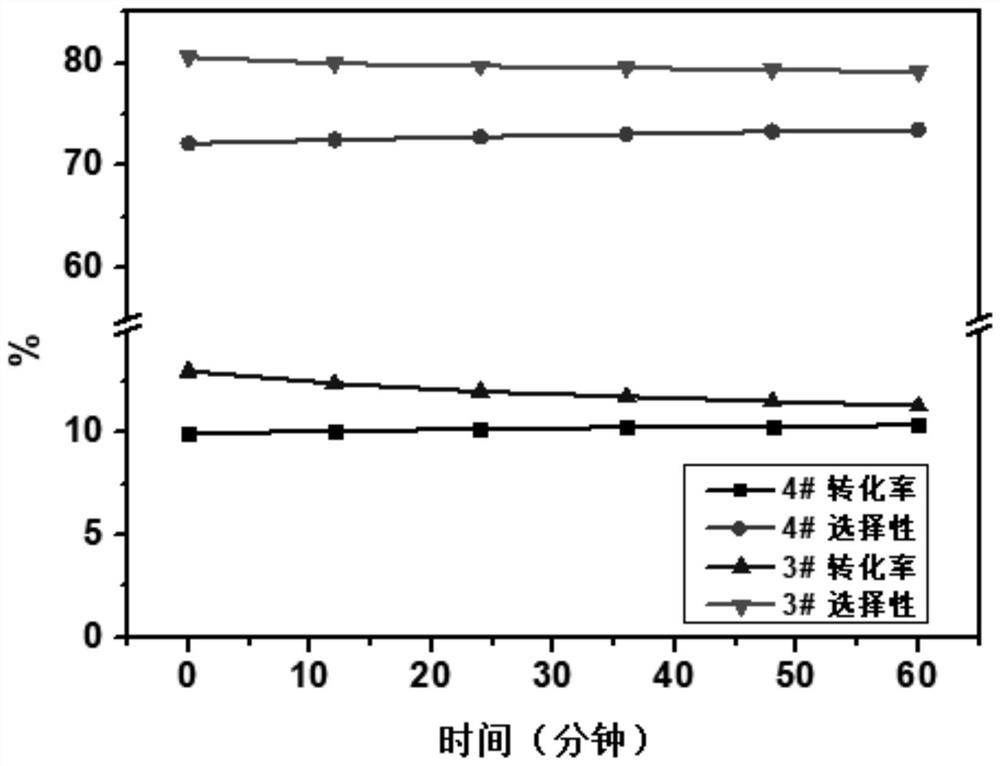

Embodiment 3

[0108] This embodiment provides a nitrogen-carbon doped modified iron-based catalyst, which is prepared by the following steps:

[0109] (1) At room temperature, weigh 1.5 g of the molecular sieve Silicalite-1 carrier and disperse it in 50 mL of ethylenediamine, stir and sonicate to obtain a homogeneous mixture I;

[0110] (2) Weigh 2.0 g of dicyandiamide and 0.483 g of iron acetylacetonate into the mixture I, continue ultrasonication and stirring for 10 h at 25° C. to fully dissolve and disperse it, and obtain the mixture II;

[0111] (3) The mixture II was rotary evaporated at 80°C, and the obtained product was vacuum-dried at 100°C overnight;

[0112] (4) Place the vacuum-dried product in a tube furnace, and in an Ar atmosphere, raise the temperature to 350°C at a rate of 5°C / min and keep it for 3h, and then rise to 650°C at a rate of 5°C / min And keep it for 2h, continue to raise the temperature to 750°C at a rate of 5°C / min and keep it for 2h, to obtain a nitrogen-carbon ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap