A rolling temperature control method for eliminating red rust on the surface of hot-rolled coil weathering steel

A rolling temperature and control method technology, applied in the direction of temperature control, etc., can solve the problems affecting the surface quality of hot-rolled coil weathering steel, increasing production costs, and high alloy costs, so as to improve surface quality, eliminate red rust, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

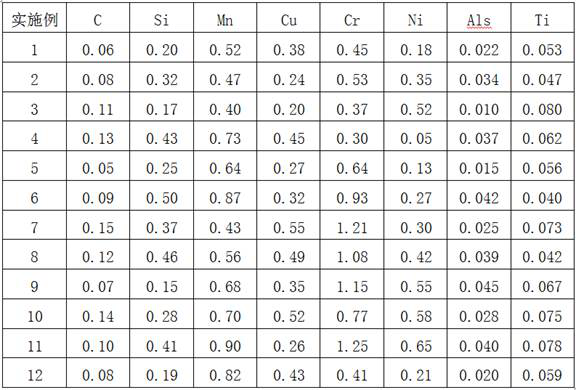

[0023] The thickness of the hot-rolled coiled weathering steel in this embodiment is 2.0 mm, and its chemical composition and mass percentage are shown in Table 1.

[0024] In this embodiment, the slab thickness of the hot-rolled weather-resistant steel coil is 200 mm, and the rolling temperature control method for eliminating the red rust on the surface of the weather-resistant steel coil of the hot-rolled coil comprises the following steps:

[0025] (1) Heating temperature control: the slab is heated in the heating furnace, and the air-fuel ratio of the heating furnace is 3.5:1. The heating temperature of the first heating section is 1150°C; the heating temperature of the second heating section is 1297°C, the soaking temperature is 1300°C, and the furnace temperature is 1260°C; the total heating time in the furnace is 200 minutes;

[0026] (2) Temperature and thickness control of rough rolling intermediate billet: rough rolling can be rolled in 7 passes, the temperature of i...

Embodiment 2

[0031] The thickness of the hot-rolled coiled weathering steel in this embodiment is 6.0mm, and its chemical composition and mass percentage are shown in Table 1.

[0032] In this embodiment, the slab thickness of the hot-rolled weather-resistant steel coil is 200 mm, and the rolling temperature control method for eliminating the red rust on the surface of the weather-resistant steel coil of the hot-rolled coil comprises the following steps:

[0033] (1) Heating temperature control: the slab is heated in a heating furnace, and the air-fuel ratio of the heating furnace is 2.5:1. The heating temperature of the first heating section is 1120°C; the heating temperature of the second heating section is 1285°C, the soaking temperature is 1290°C, and the furnace temperature is 1250°C; the total heating time in the furnace is 165min;

[0034] (2) Temperature and thickness control of rough rolling intermediate billet: 7 passes of rough rolling, the temperature of intermediate billet at ...

Embodiment 3

[0039] The thickness of the hot-rolled coiled weathering steel in this embodiment is 7.8 mm, and its chemical composition and mass percentage are shown in Table 1.

[0040] In this embodiment, the slab thickness of the hot-rolled weather-resistant steel coil is 200 mm, and the rolling temperature control method for eliminating the red rust on the surface of the weather-resistant steel coil of the hot-rolled coil comprises the following steps:

[0041] (1) Heating temperature control: the slab is heated in a heating furnace, and the air-fuel ratio of the heating furnace is 3.0:1. The heating temperature of the first heating section is 1050°C; the heating temperature of the second heating section is 1261°C, the soaking temperature is 1263°C, and the furnace temperature is 1220°C; the total heating time in the furnace is 161min;

[0042] (2) Temperature and thickness control of rough rolling intermediate billet: 5 passes of rough rolling, the temperature of intermediate billet at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com