Gear welding equipment for manufacturing large gear

A large-scale gear and welding equipment technology, applied in the field of gear manufacturing, can solve problems such as not easy to control the concentricity of the inner and outer parts, inconvenient moving and handling, and the influence of gear transmission, so as to ensure concentricity, processing quality and rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

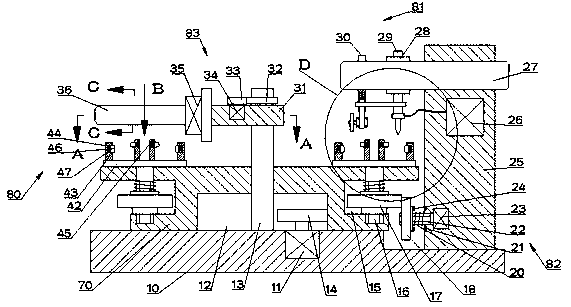

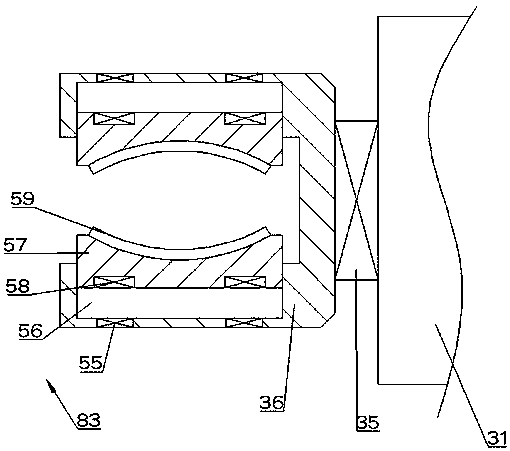

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

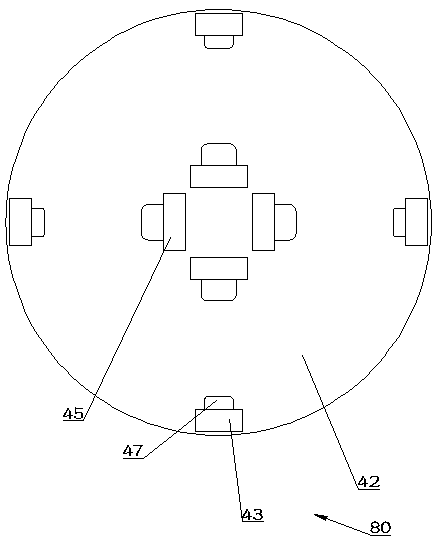

[0019] refer to Figure 1-5 , according to an embodiment of the present invention, a gear welding device for manufacturing large gears, including a base 10, a rotating plate 70 is installed on the top surface of the base 10, and the center of the rotating plate 70 is aligned with the vehicle. Rotate and install the placing plate 42, which is provided with a clamping part 80 that can clamp the inner and outer parts of the gear. The outer limiting plate 43 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com