Preparation and processing method of corrugated carton

A technology of corrugated cartons and processing methods, which is applied in the field of corrugated paper processing, can solve the problems of poor edge compression strength, reduced strength, and poor applicability of corrugated cartons, achieve good protection and strengthening effects, and ensure the effect of overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

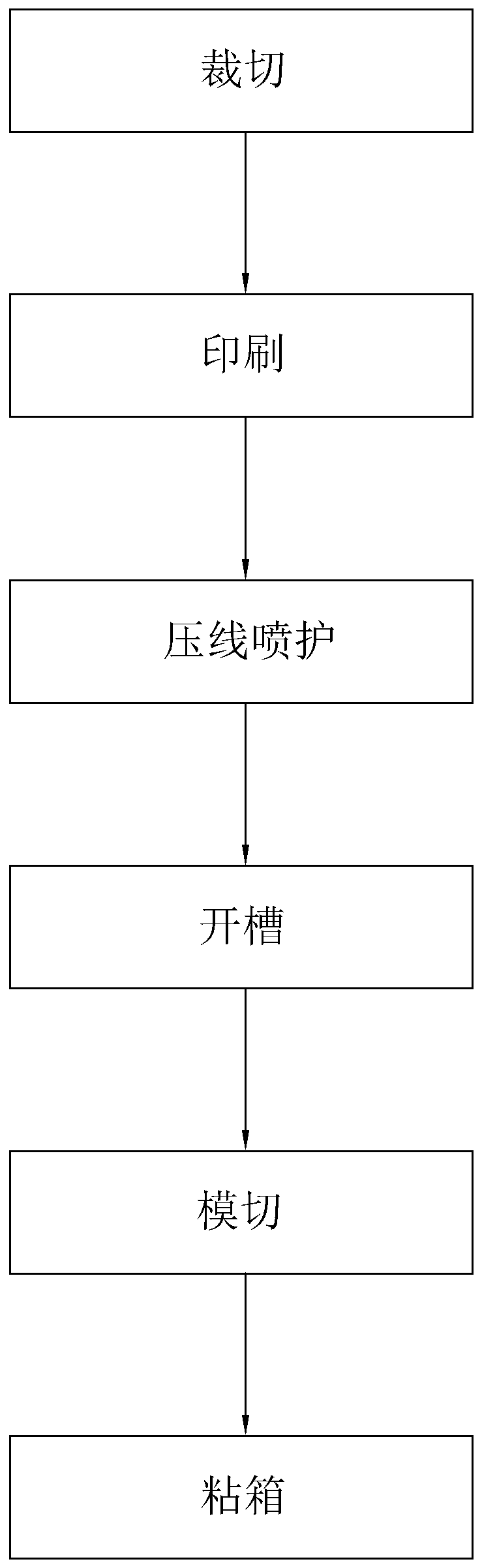

[0042] Example 1: A method for preparing and processing corrugated boxes, which is prepared through the following steps:

[0043] Step one, cutting, cutting the corrugated paper raw materials to obtain corrugated cardboard;

[0044] Step two, printing, transfer the cut corrugated cardboard to the printing machine, select the graphic printing plate, and print the corrugated cardboard to obtain the printed matter;

[0045] Step three, pressure line spray protection: the printed matter is folded into longitudinal and horizontal indentation through the creasing wheel, and pre-molded to mark the incision line, and then spray solid protective agent on the longitudinal indentation, horizontal indentation and incision line , The spraying amount of the solid protective agent on the printed matter is 7g / ㎡, and the spraying range extends from the longitudinal indentation, the transverse indentation and the incision line to both sides by 4cm, the drying temperature is 70℃, and the time is 7.5min...

Embodiment 2-5

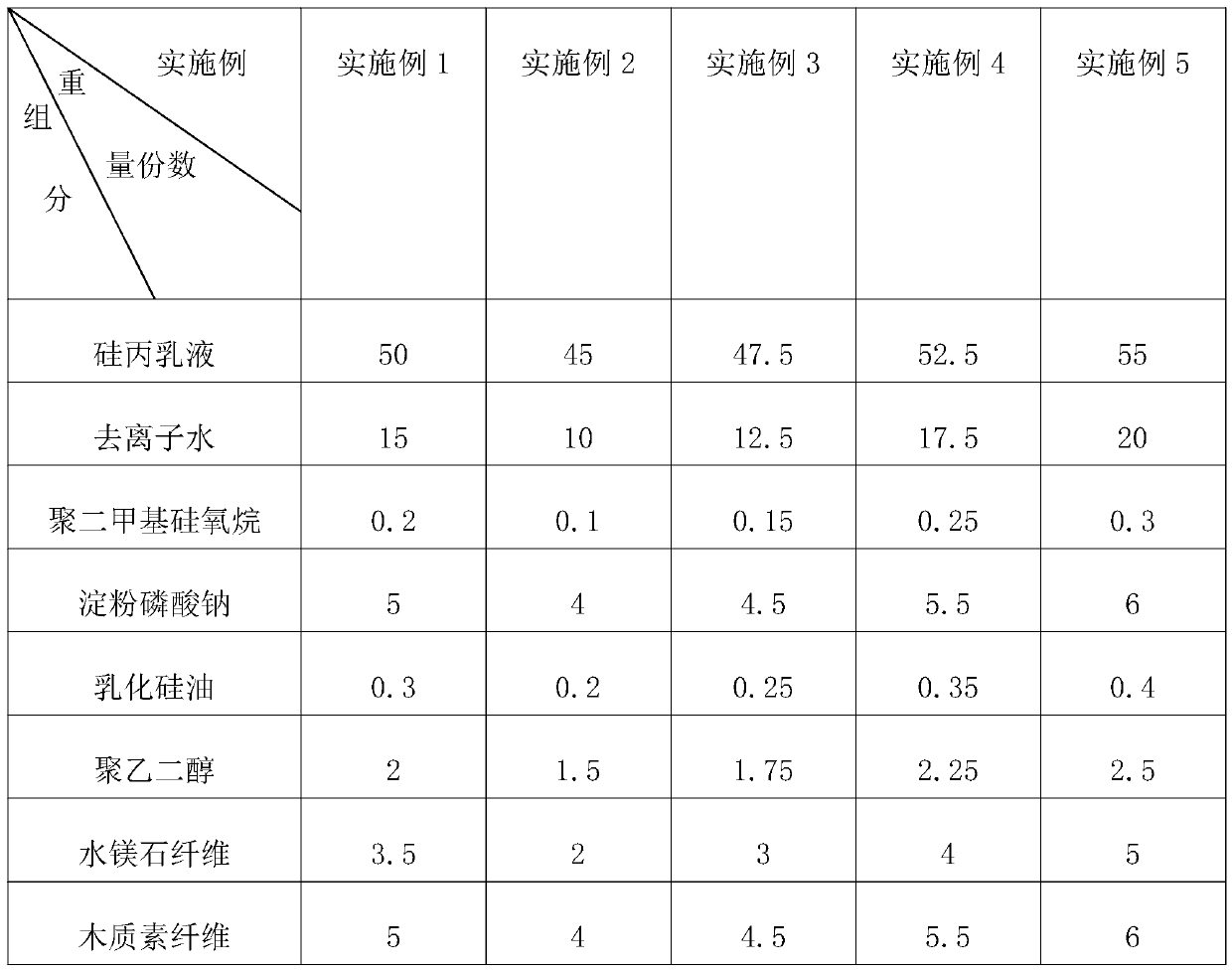

[0050] Example 2-5: A preparation and processing method of a corrugated box. The difference from Example 1 is that the components of the solid protective agent in step 3 and their corresponding weight parts are shown in Table 1.

[0051] Table 1 Each component and its parts by weight in Examples 1-5

[0052]

Embodiment 6

[0053] Example 6: A preparation and processing method of corrugated boxes. The difference from Example 1 is that the mass of polydimethylsiloxane in the solid protective agent in step 3 is replaced with polyacrylic acid.

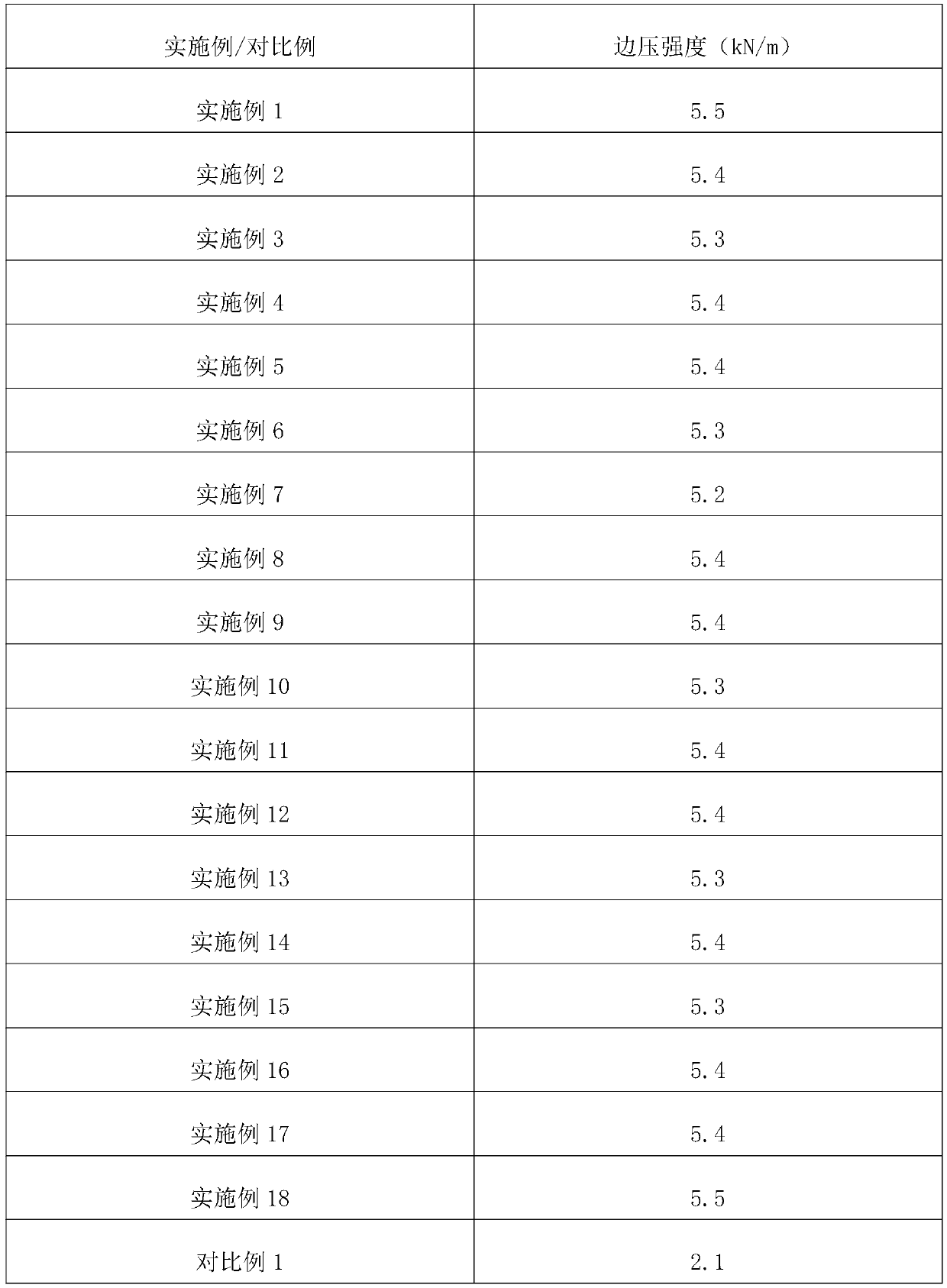

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com