Bearing beam self-elevating type hoistway construction elevator

A technology for construction elevators and load-bearing beams, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve problems such as increased power consumption and difficulty in retracting and retracting steel wire ropes, and achieve large bearing capacity, stable support, and structural stability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

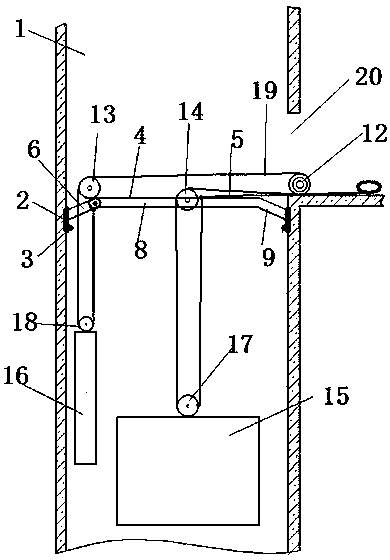

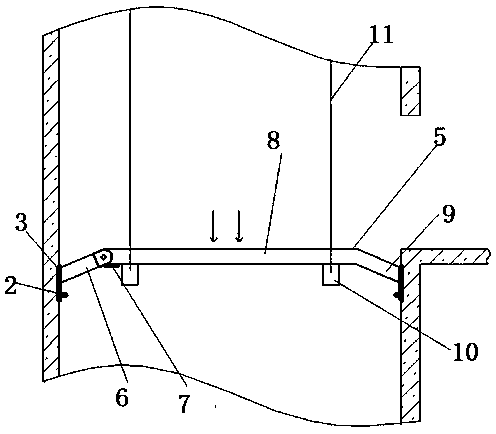

[0017] A specific embodiment of the foldable load-bearing beam type self-elevating hoistway construction elevator involved in the present invention is as follows: figure 1 with figure 2 As shown, the construction hoist includes a cage, counterweight, load-bearing beam, traction machine 12, steel wire rope, etc., and also includes other parts such as guide rails, limit devices, protection devices, and control systems. The technology is basically the same, and the detailed working principle and process are not introduced.

[0018] Among them, for the load-bearing beam, the function of the load-bearing beam is mainly to realize the support of the hanging cage, counterweight, corresponding pulley and other equipment. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com