Method for performing hot frowsty treatment on steel slag by applying steel slag frowsty pot

A technology of steel slag and stuffy pot, which is applied in the field of hot stuffy treatment of steel slag in a steel slag stuffy pot, can solve problems such as general digestion effect, and achieve the effect of promoting recycling and thorough digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

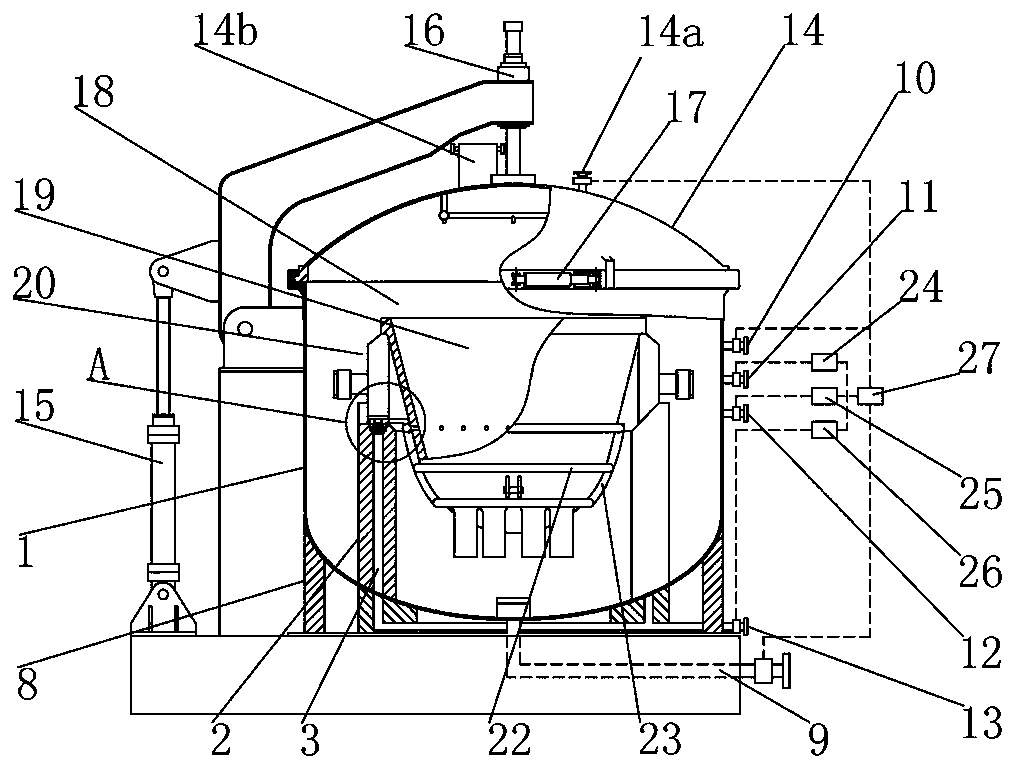

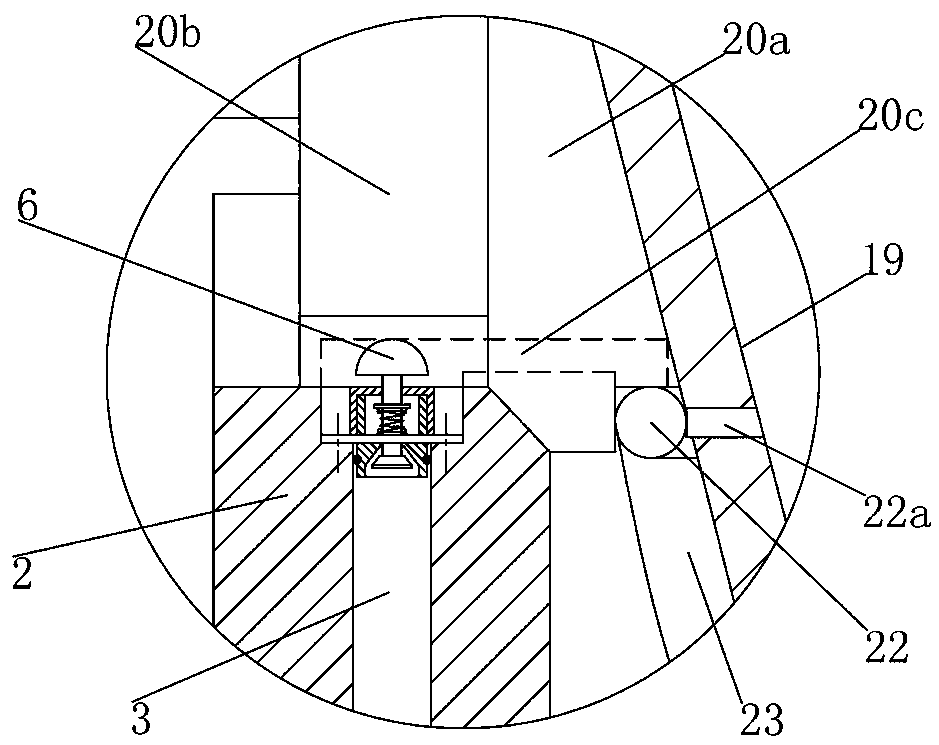

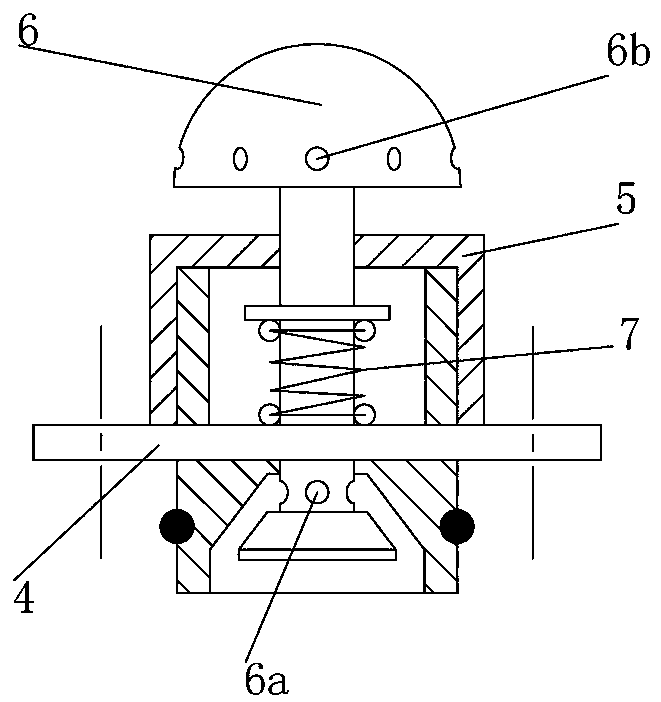

[0030] Such as Figure 1-5 As shown, the above-mentioned steel slag stuffy pot includes a pot body 1, a sealing device, and also includes a slag bag 18 placed inside the pot body 1; Package seat 2; the lower end of the above-mentioned pot body 1 is provided with a bottom support 8, and is also provided with a drain pipe 9 connected with the inside of the pot body 1; the outside of the above-mentioned pot body 1 is provided with an exhaust port 10 and a monitoring port in turn from top to bottom 11. Inert gas inlet 12, exhaust gas inlet 13; each of the above-mentioned slag bag seats 2 is provided with a waste gas channel 3 connected with the exhaust gas inlet 13; each outlet of the above-mentioned exhaust gas channel 3 is provided with An exhaust gas connection mechanism.

[0031] The capping device includes an end cap 14, a turning mechanism 15 for opening and closing the end cap 14, a pressing mechanism 16 for pressing the end cap 14, and a locking mechanism for locking the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com