A textile machine equipment with high stability and adjustable lifting

A high-stability and adjustable technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of high cost, component deviation and damage, and difficulty in maintenance and replacement, so as to reduce the difficulty of lifting and avoid Shaking damage, the effect of ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

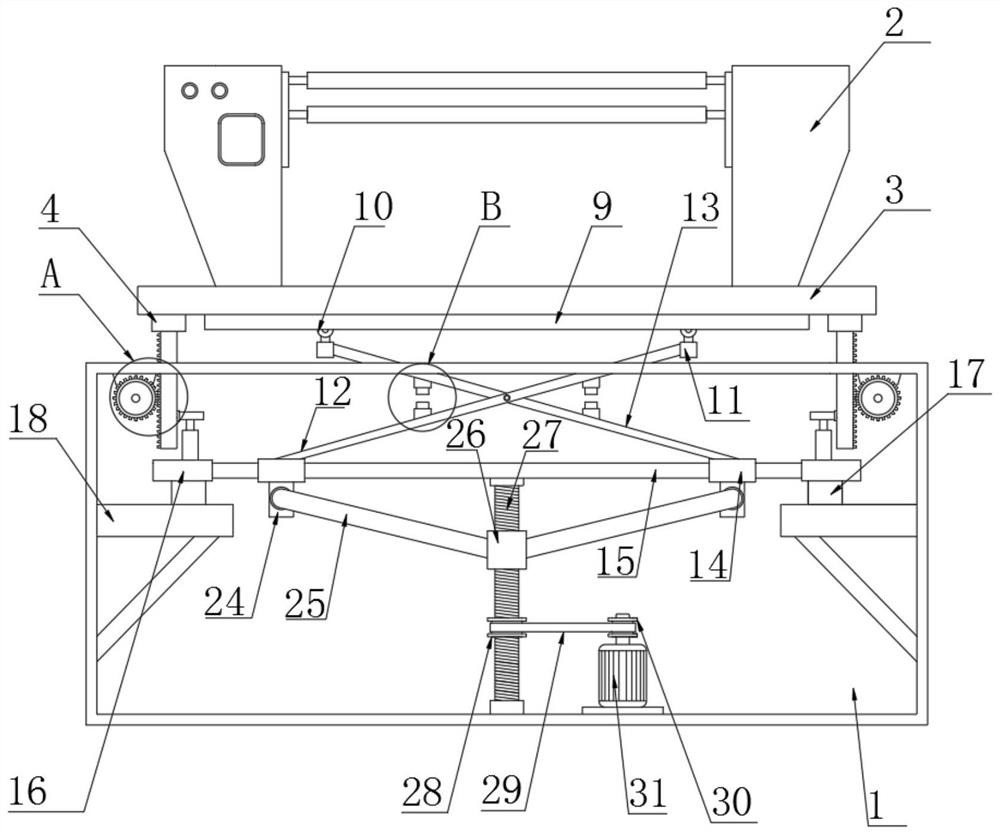

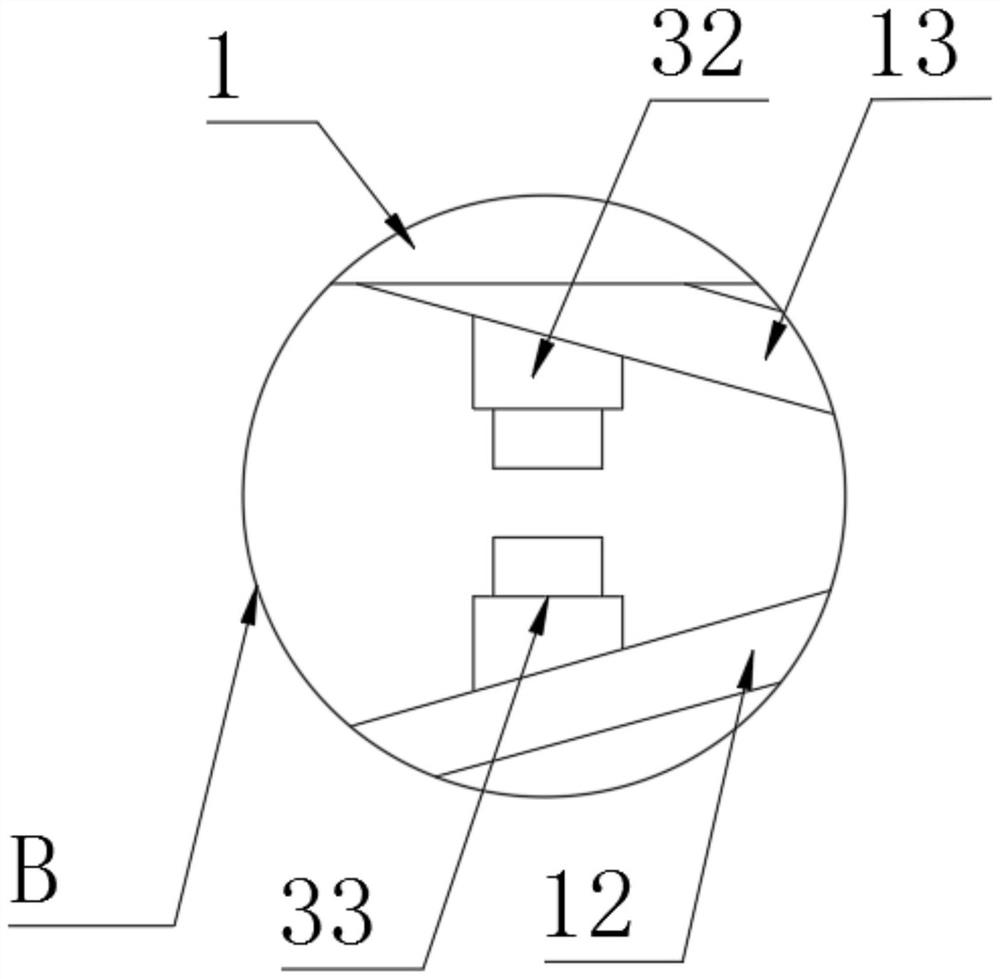

[0039] The specific implementation method is: by setting the controller 34 to control the servo motor 31, the first electromagnet 32 and the controller 34 with one key, the intelligent lifting adjustment of the device is realized, the difficulty of lifting the textile machine body 2 is reduced, and the lifting adjustment time is increased. High efficiency improves the intelligence of the device.

[0040] The specific implementation method is:.

[0041] The working principle of the present invention:

[0042] Preparation stage: first install all components, and then calculate the height of the textile body 2 that needs to be adjusted;

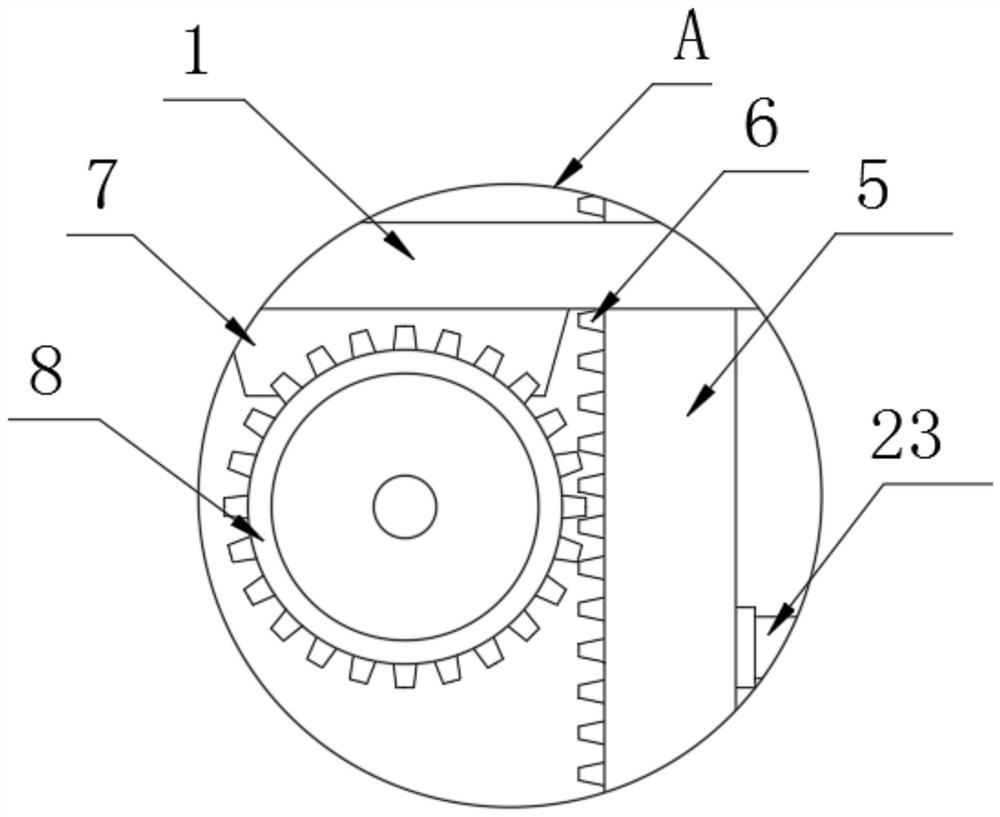

[0043] Working stage: rising stage: start the controller 34, by changing the flow direction of the first electromagnet 32 and the second magnet 33, the electrodes of the first electromagnet 32 and the second magnet 33 close to each other are the same, and are driven by the magnetic force. The first pull rod 12 and the second pull rod 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com