Rapid detection and evaluation method for light soil roadbed

An evaluation method and soil subgrade technology, which can be applied in the field of foundation soil survey, foundation structure engineering, construction, etc., can solve the problems of lack of detection and evaluation methods for the quality of deep subgrade pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

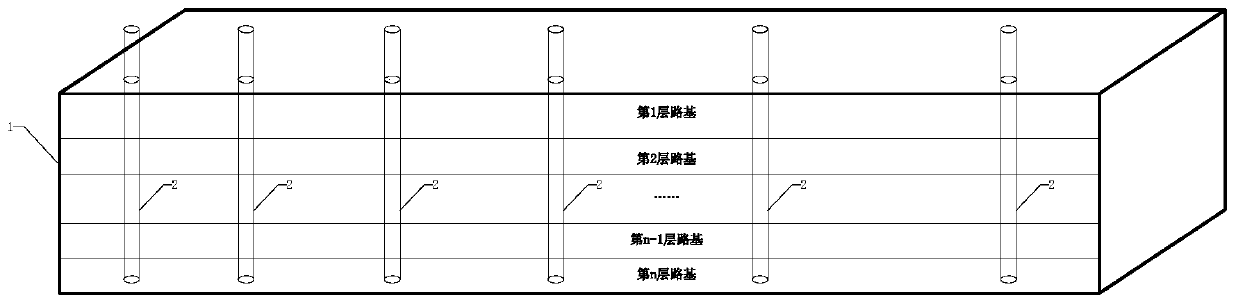

[0135] A road project uses light soil as the subgrade filling material, the design compressive strength is ≥1.2MPa, and the subgrade filling height is 1.2m. The single filling area of the light soil subgrade is 20.0×16.0m, the single filling height is 0.4m, and the subgrade is poured in three layers: lower, middle and upper. The construction mix ratio of light soil is shown in the table below.

[0136]

[0137] Note: Conch brand PO42.5 ordinary Portland cement is used for cement, HTW-1 composite foaming agent is used as foaming agent, and the dilution ratio of foaming agent is 1:50.

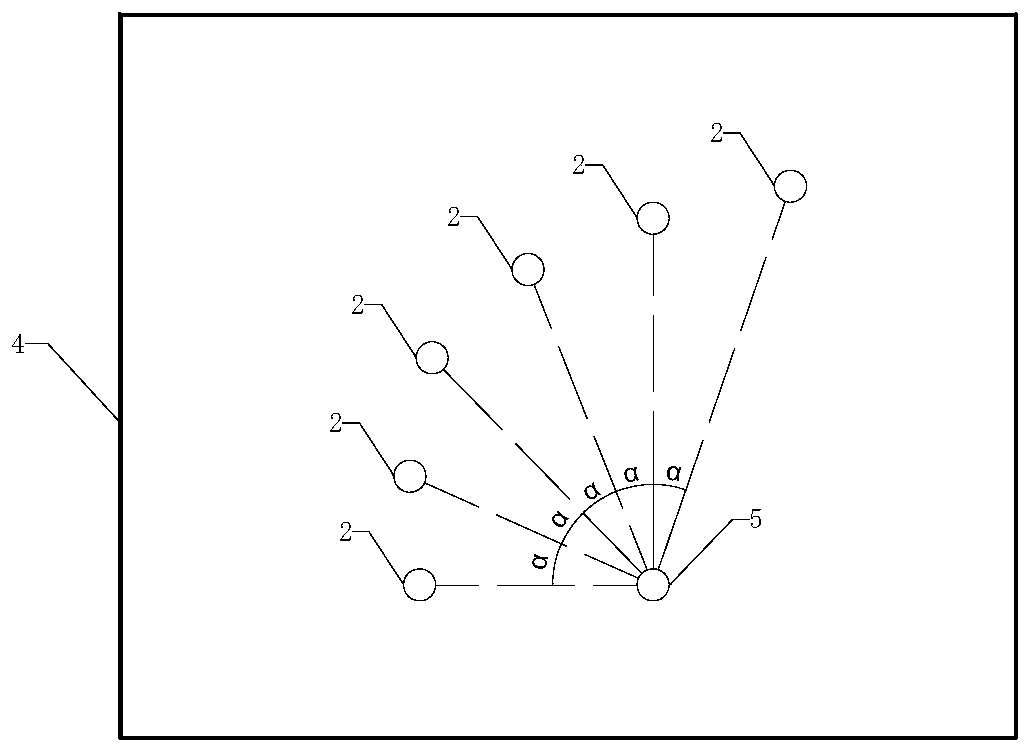

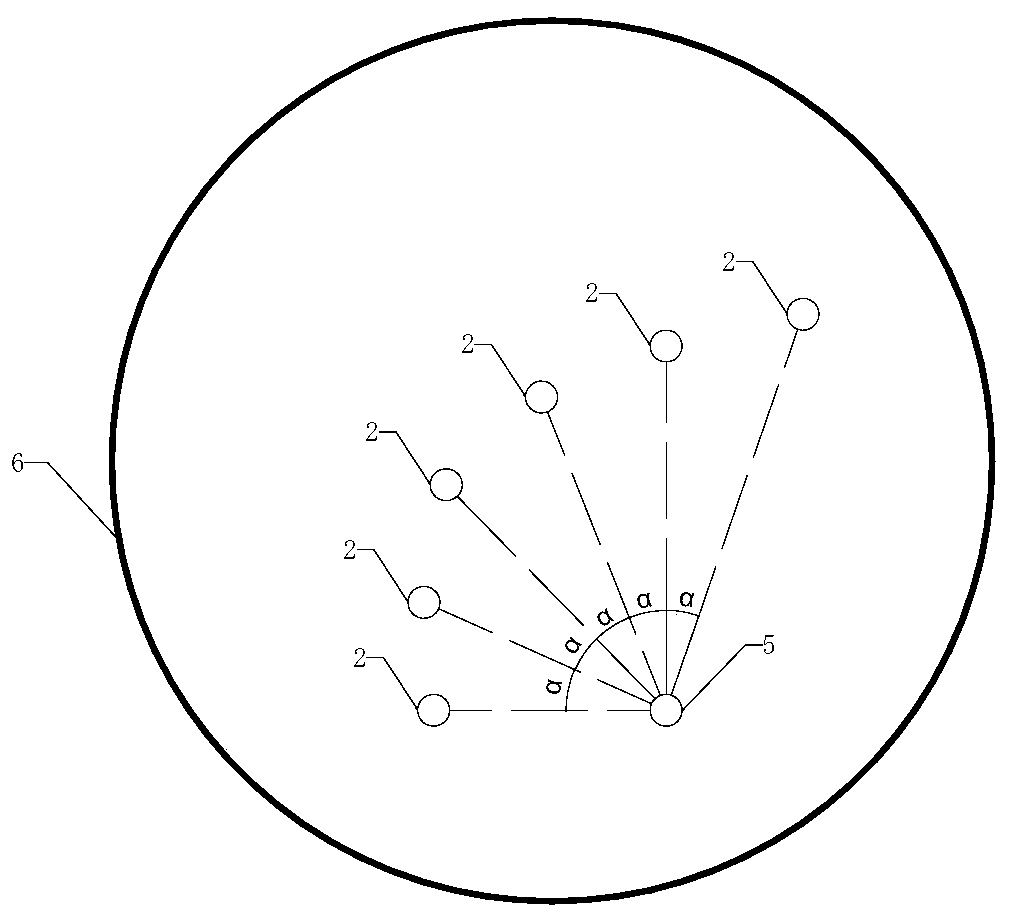

[0138] First, determine the optimal detection distance L b : The light soil roadbed belongs to the strip roadbed, in order to determine the best detection distance L b , On one side of the subgrade test section, acoustic tubes with spacings of 0.4-1.0m, 1.2m, 1.5m and 2.0m are buried linearly, and three groups of parallel tests are set up. According to the test results, when the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com