Crest fixed metal roof structure and construction method thereof

A metal roof, wave crest technology, applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve the problem of increased number of nail holes, increased construction cost, long construction period of metal roof, low impermeability and durability of bottom plate, etc. problems, to achieve the effect of reducing fixed installation time, meeting green construction requirements, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

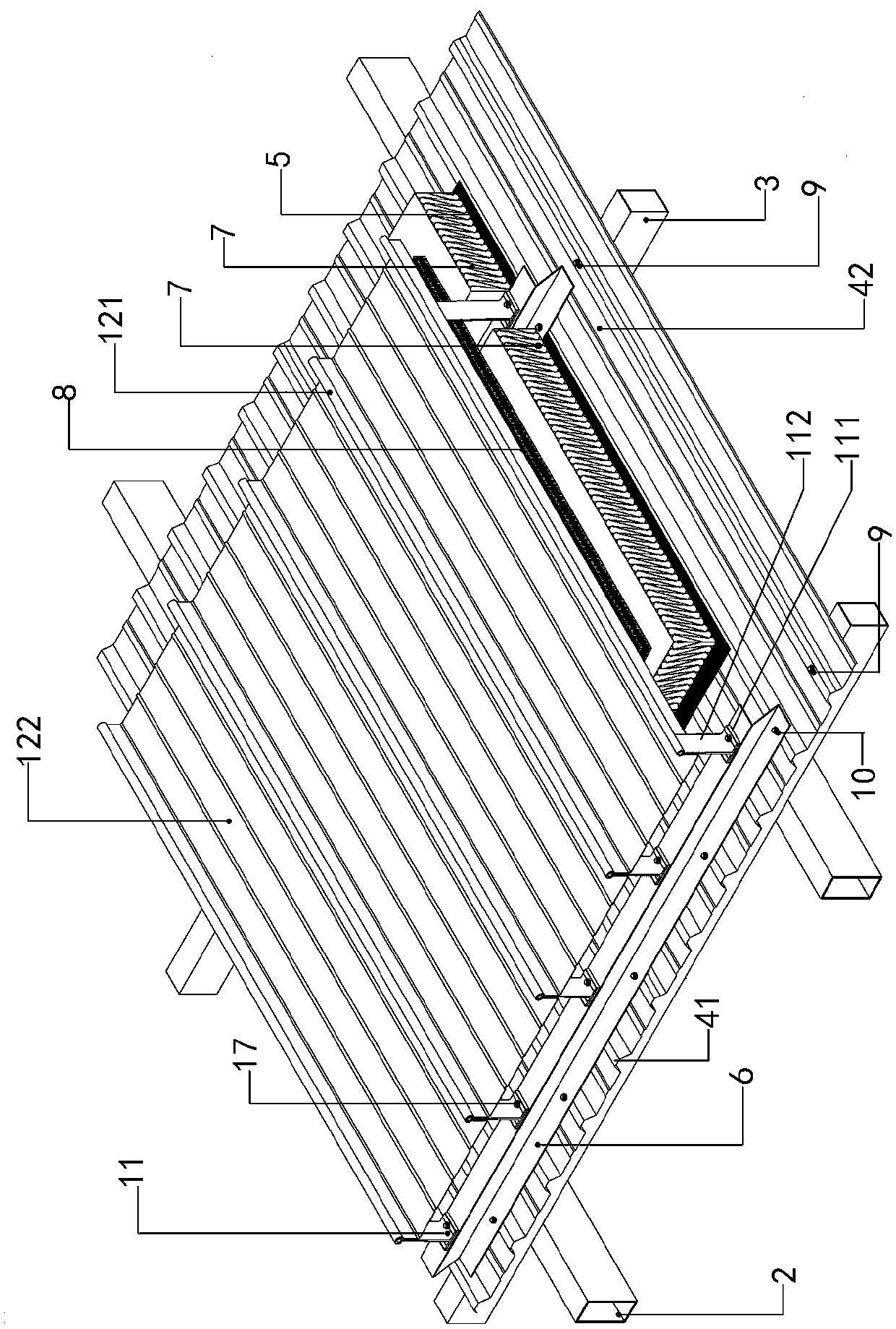

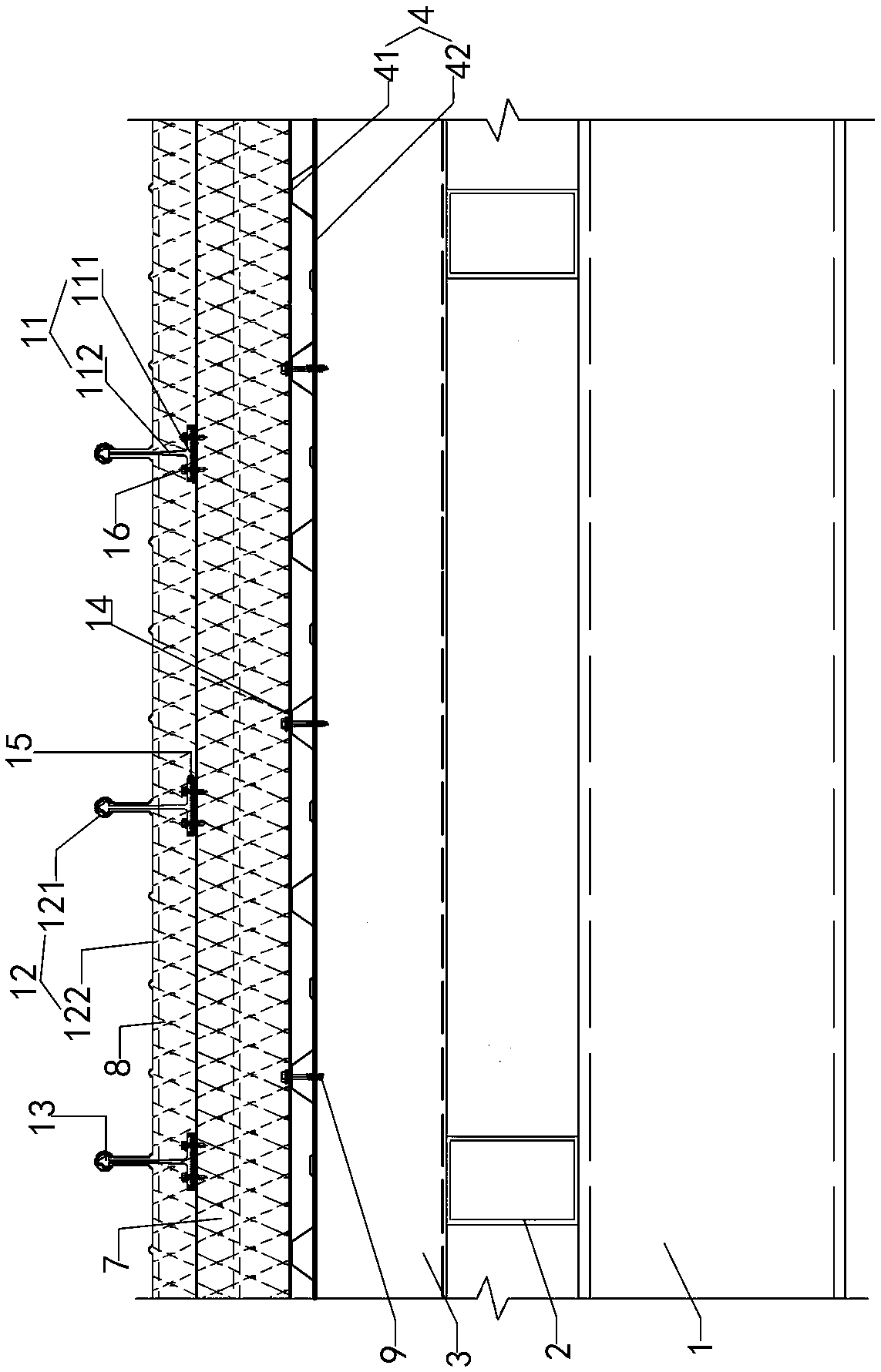

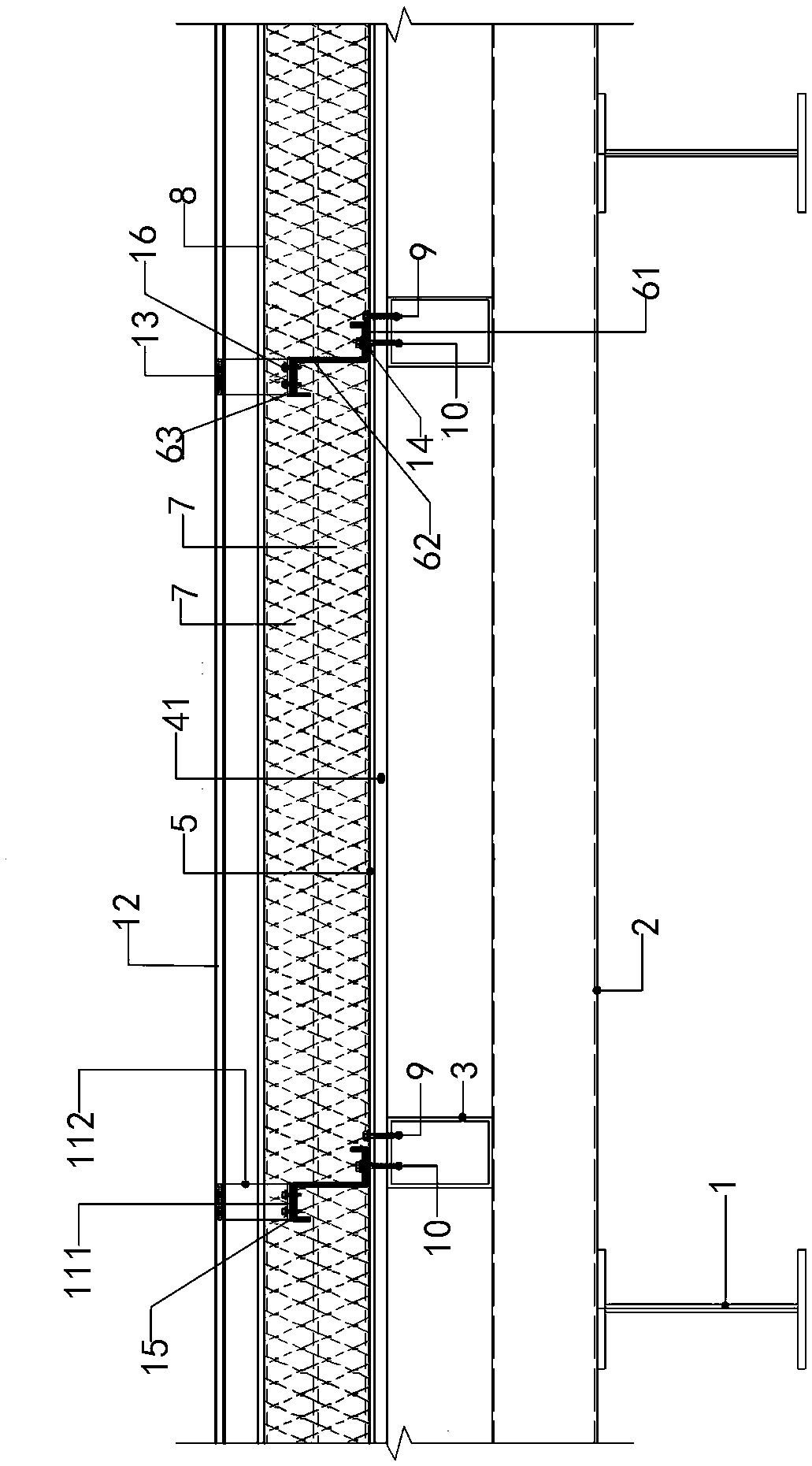

[0059] Examples see Figure 1-3 As shown, a wave crest fixed metal roof structure includes roof steel beams 11, roof main purlins 2, roof sub-purlins 3, metal roof bottom plate 4, vapor barrier layer 5, Z-shaped keel 6, insulation layer 7, waterproof vapor permeable membrane 8 and the roof panel, the direction of the roof drainage slope is longitudinal, and the vertical direction of the roof drainage slope is horizontal.

[0060] The roof steel girders 1 are arranged at intervals along the transverse direction.

[0061] The roof main purlins 2 are arranged longitudinally at intervals throughout the length, and the roof main purlins 2 are fixedly connected to the upper side of the roof steel beam 1 .

[0062] The roof sub-purlins 3 are arranged along the transverse interval, and the roof sub-purlins 3 are fixedly connected to the upper side of the roof main purlins 2 .

[0063] The metal roof bottom plate 4 is fully paved on the upper side of the roof sub-purlins 3, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com