Method for predicting low-temperature ultrahigh-cycle fatigue life of high-strength steel

A technology for fatigue life prediction and high-strength steel, which is applied in the direction of testing material strength and strength characteristics by using one-time impact force, testing material strength by applying repeated force/pulsation force, etc. High-strength steel low-temperature ultra-high cycle fatigue life and other issues, to achieve the effect of economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

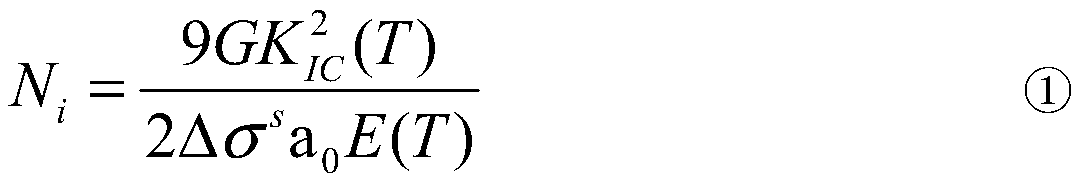

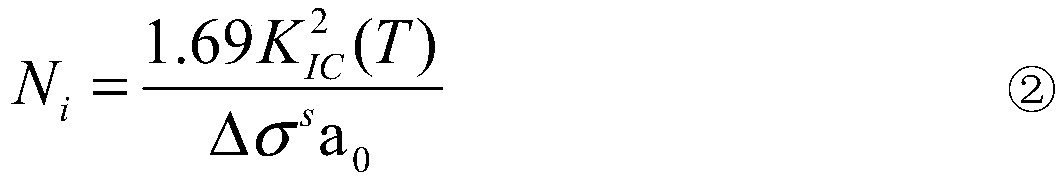

[0021] Taking 42CrMo steel as the research object, the high-strength low-temperature ultra-high-cycle fatigue life prediction method includes the following steps:

[0022] (1) Using the ultrasonic fatigue method to conduct ultra-high cycle fatigue tests on 42CrMo steel under a temperature environment of -20°C, the test frequency is 20kHz, and obtain material fatigue strength-life data;

[0023] (2) The impact energy of 42CrMo steel at different low temperatures (193K, 213K, 233K, 253K, 273K, 293K) are: 43, 56, 83, 112, 118, then the relationship between impact energy and temperature:

[0024] CNV=-433.39+3.467T-0.00531T 2 ;

[0025] (3) According to the relationship between material fracture toughness and impact energy, the relationship between fracture toughness and low temperature can be obtained;

[0026] K IC =14.6×(-433.39+3.467T-0.00531T 2 ) 0.5

[0027] (4) Use metallographic polishing method to measure the size of inclusions in high-strength materials a 0 =35.2u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com