TiN-coat-coated mold

A coating and mold technology, applied in the field of ion coating molds, can solve the problems of reducing the mechanical properties of the coating, the coating quality is difficult to control, and the coating has many pores, so as to improve the internal fracture mechanical properties, easy to promote, and fracture toughness big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

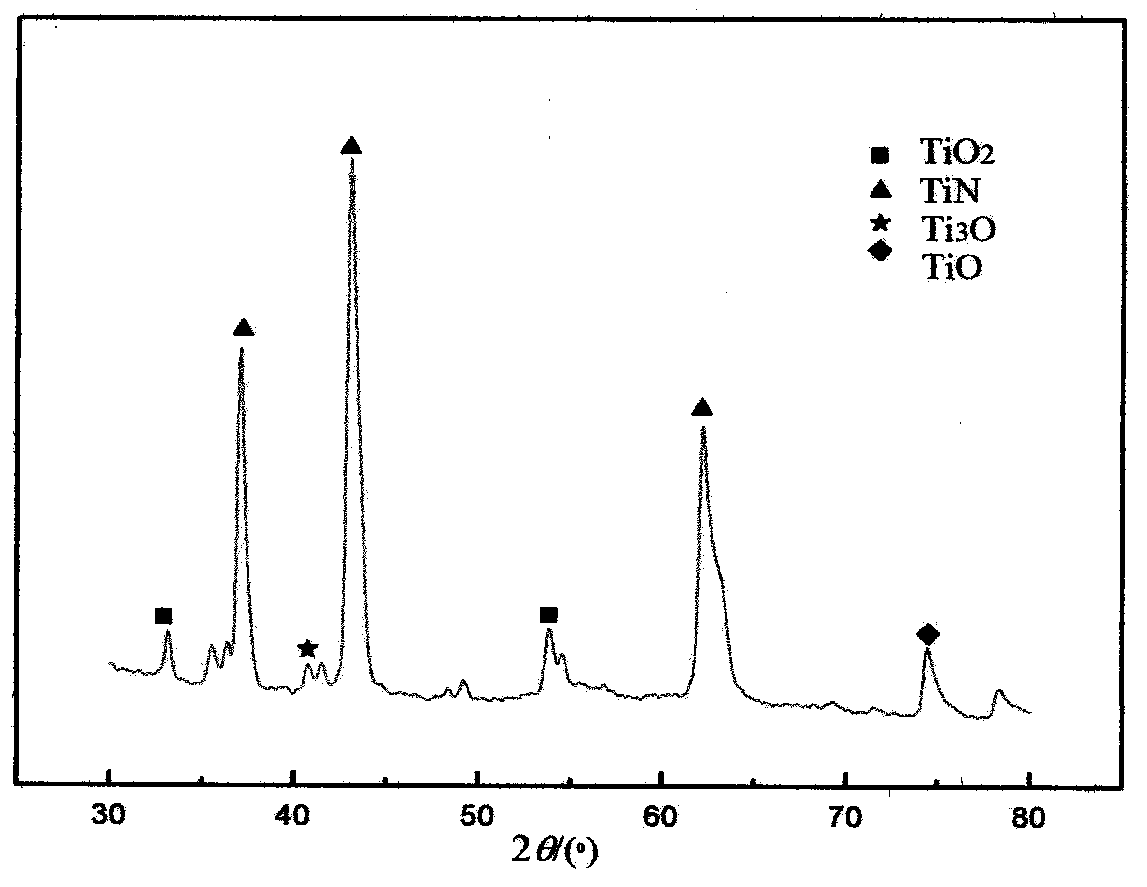

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 coating

[0026] The preparation process of the coating is divided into four stages: preparation of TiN agglomerated powder, mold surface pretreatment, spraying parameter optimization, and spraying. The steps of the four stages are as follows:

[0027] (1) preparing TiN agglomerated powder;

[0028] (1-1) Atomize TiN powder with a powder particle size of 1-5 μm as a raw material;

[0029] (1-2) Mixing the atomized TiN powder and binder into the agglomeration equipment for agglomeration, drying the agglomerated powder, and granulating;

[0030] (1-3) passing the agglomerated powder through a -200 mesh to +400 mesh powder sieve to obtain a TiN agglomerated powder with a particle size of 40-80 micron micron spherical agglomerates.

[0031] The powder includes atomic fractions of Ti-72% and N-28%, and after agglomeration, spherical agglomerates with a particle diameter of 40-80 μm are formed.

[0032] (2) Mold surface pretreatment;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com