Method for evaluating characteristic life of metal structure of foundry crane based on track joint defects

A technology for rail joints and metal structures, which is used in computer-aided design, special data processing applications, instruments, etc., and can solve problems such as the inability to evaluate the characteristic life of metal structures and the fatigue failure of structural base materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

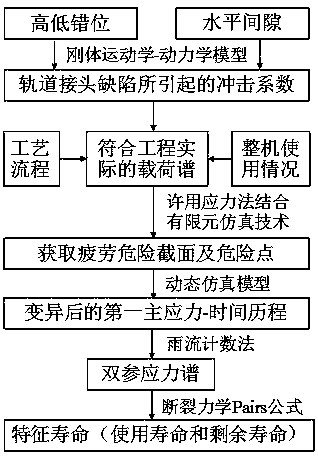

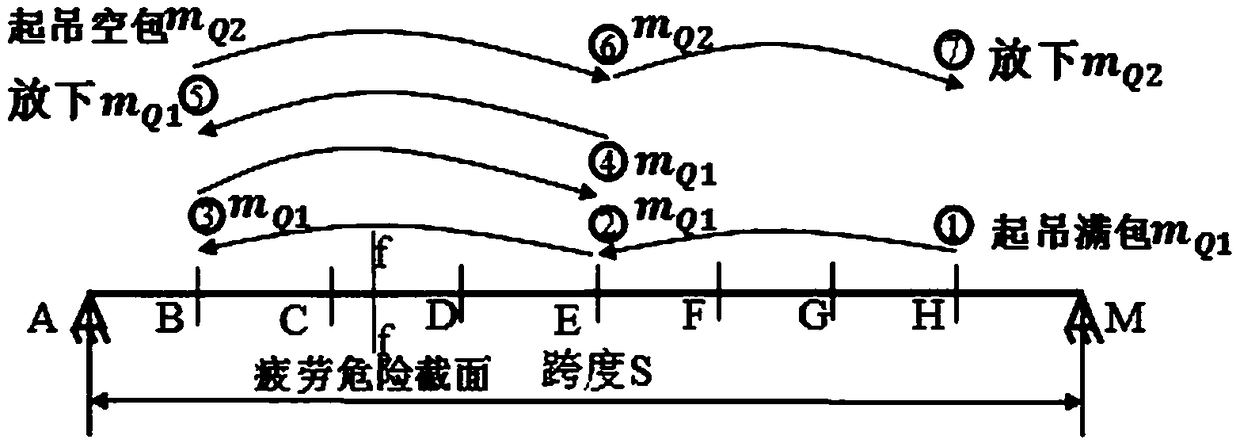

[0064] A method for evaluating the characteristic life of cast crane metal structures based on rail joint defects, the specific steps are as follows.

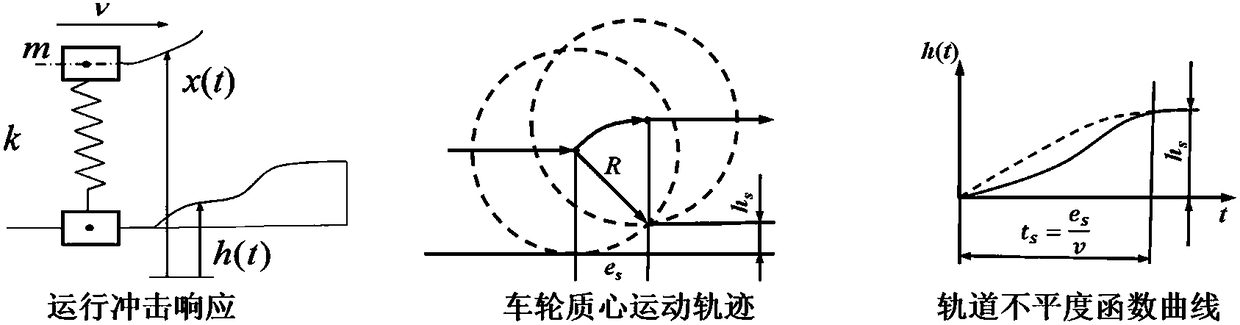

[0065] Step 1: If figure 1 and 2 As shown, according to the wheel-rail coupling kinematics-dynamics model under the high-low misalignment of the rail joint of the casting crane, the maximum acceleration of the system when the casting crane crosses the high-low misalignment of the rail joint is deduced (see formula (1) and formula (2)), through Equation (3) calculates the impact coefficient φ caused by the crane running under the measured high-low misalignment track joint 4 , the results are shown in Table 1.

[0066] Kinematics-dynamics model of wheel-rail coupling under height misalignment or horizontal clearance of casting crane rail joints:

[0067]

[0068] Among them, m is the mass of the casting crane; k is the stiffness of the crane; h i (t) is the roughness function of the track, when there is a high-low misalign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com