Method for testing adhesive strength of interface crack expanding resistance characterizing coating

A technology of crack propagation resistance and adhesion strength, applied in the field of inspection, can solve the problems of difficult metal substrates in lithography microfabrication methods, complex sample fabrication process, measurement error limitations, etc., to achieve rich measurement methods, simple testing, and improved measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

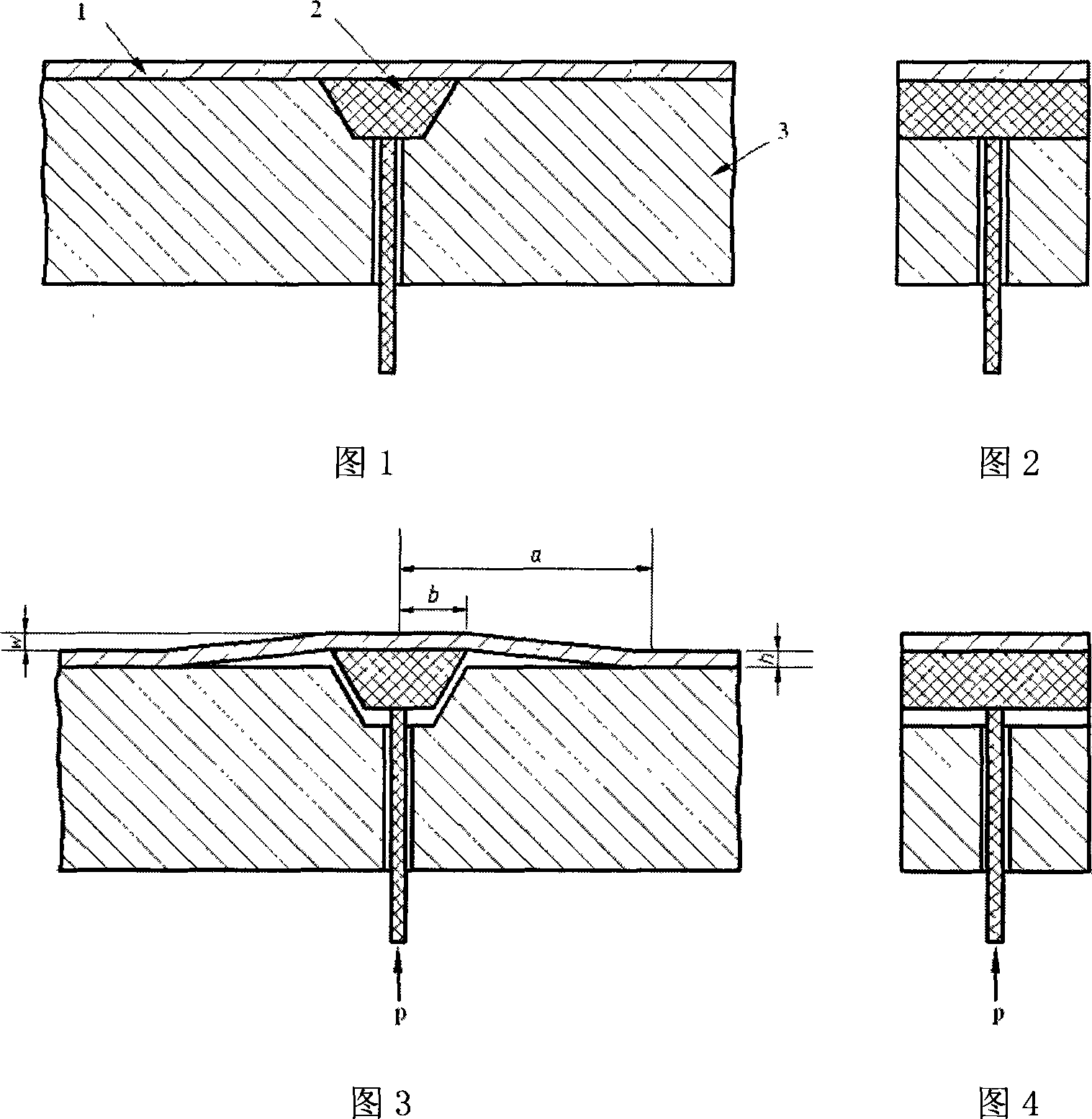

[0027] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0028] As shown in Figures 1-4, this embodiment can be carried out according to the following steps:

[0029] Step 1: Machining a wedge-shaped groove on the substrate 3 without coating, and preparing a wedge-shaped block 2 that can closely fit with the wedge-shaped groove.

[0030] Step 2: Put the wedge block 2 into the groove to form a smooth surface.

[0031] Step 3: Using a coating process, a layer of coating 1 is attached to the surface of the substrate 3 that matches the wedge-shaped block 2 .

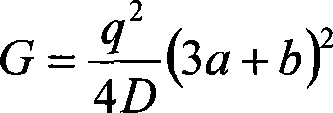

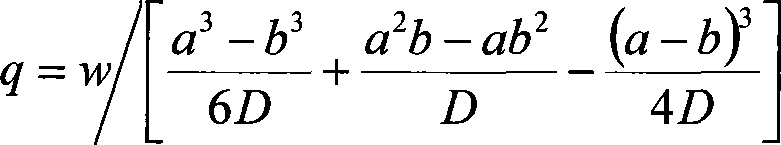

[0032] Step 4: The wedge block 2 is pushed by the loading system to cause a vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com