A Digital Holographic Microscopic Imaging Equipment for Irregular Precision Parts

A digital holographic microscopic and precision parts technology, applied in the direction of instruments, etc., can solve the problems of dust, affecting the accuracy of microscopic observation of parts, and errors of microscopic observation of parts, so as to avoid moisture damage, facilitate classified storage, and use safely convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

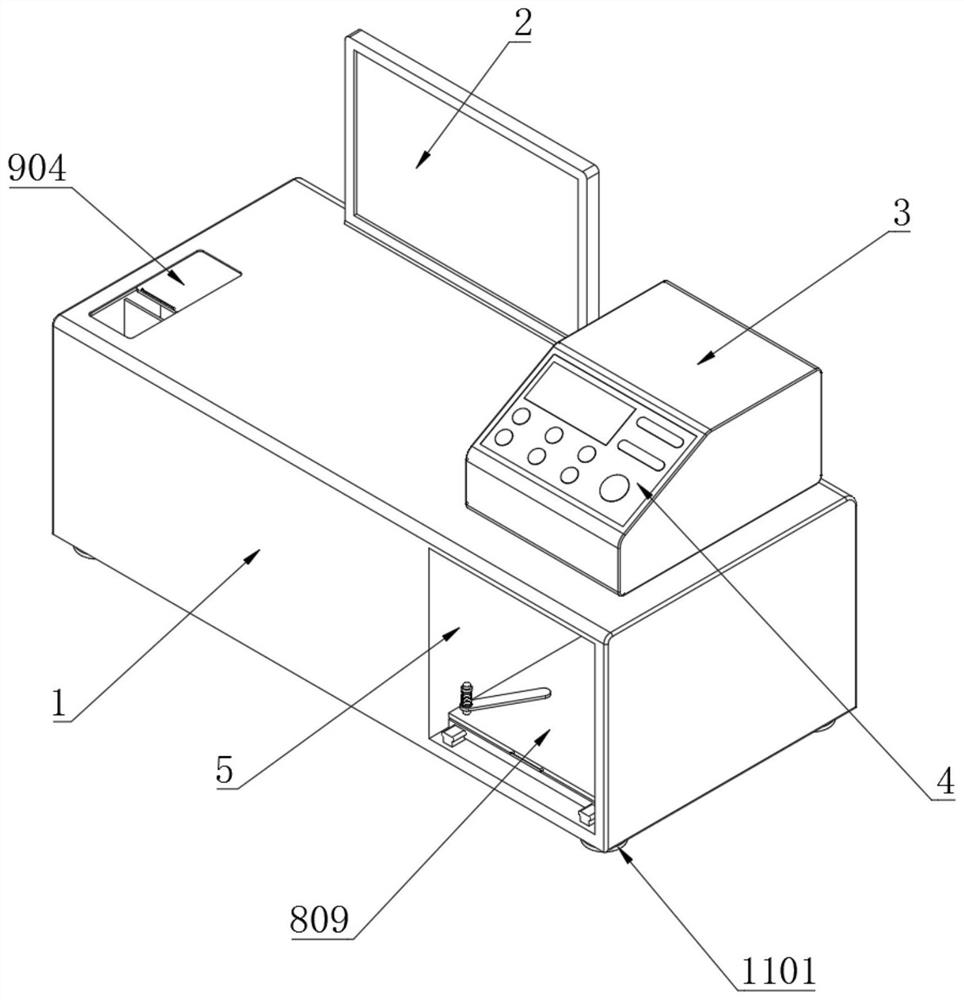

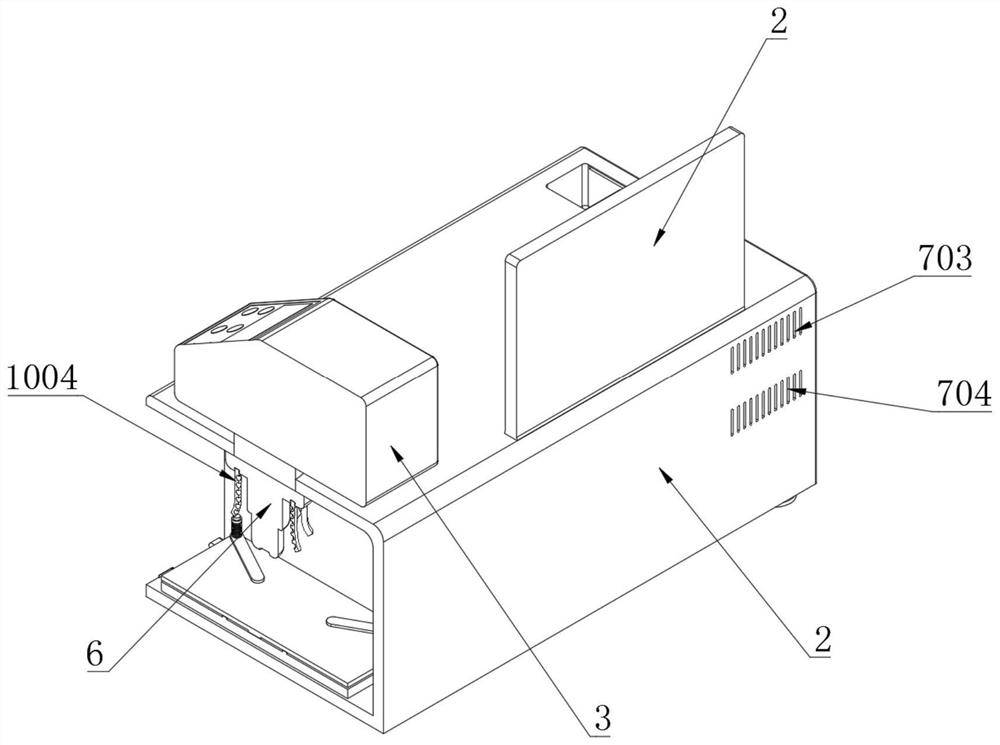

[0048] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a digital holographic microscopic imaging device for irregular precision parts, including an imaging box 1, the top of the imaging box 1 is rotatably mounted with a display panel 2, and the top of the imaging box 1 corresponds to the display panel 2 A processing and imaging cabinet 3 is installed at one side, and one end of the processing and imaging cabinet 3 is connected with a control panel 4 in the future, and one end of the imaging cabinet 1 is provided with a placement slot 5, and the bottom end of the processing and imaging cabinet 3 is connected with a microscopic observation lens 6;

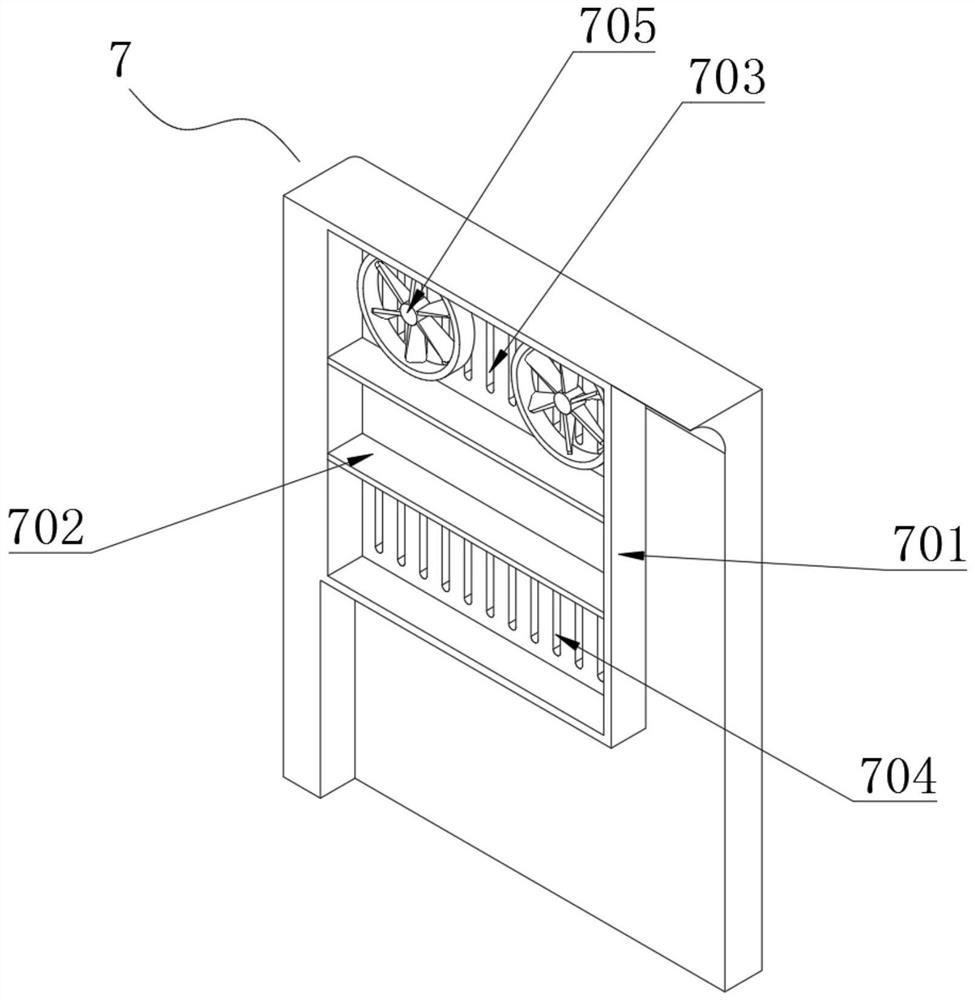

[0049] The other end of imaging box body 1 is connected with dust removal collection mechanism 7, and dust removal collection mechanism 7 comprises air extraction outer bin 701, barrier inner bin 702, exhaust hole 703, air intake hole 704, exhaust fan 705, filter screen 706, collecting Wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com