Adapter connector

A technology for adapting connectors and connecting ends, which is applied in the directions of connection, installation of connecting components, and components of connecting devices, etc., can solve the problems of poor tolerance between connectors and printed boards, inconvenient assembly and maintenance, etc., and achieve the layout method. Optimized, the overall structure is easy to maintain, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

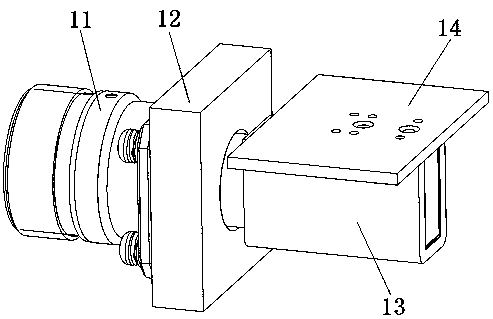

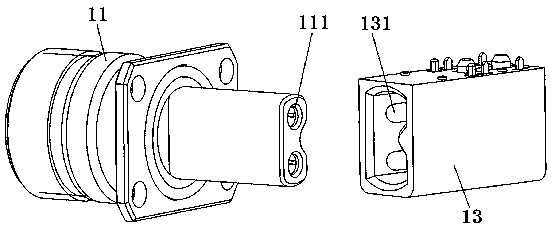

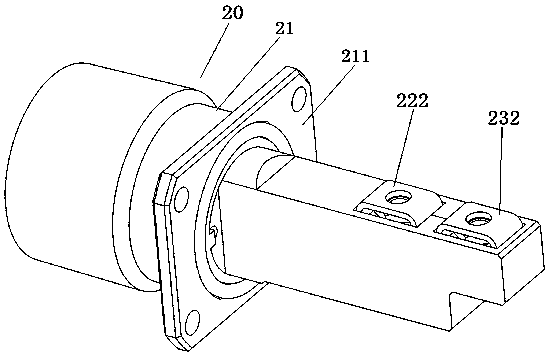

[0045] Embodiment 1 of the transfer connector in the present invention: the transfer connector in the present invention is used to realize the conduction of the internal and external circuits of the equipment, and the plug-in end of the transfer connector is mated with the adapter plug in the external circuit, and the transfer The connection end of the connector is used to connect with the printed board in the device to realize the transmission of electrical signals. like image 3 As shown, the transfer connector 20 includes a housing 21, the housing 21 is made of insulating material, a square plate 211 is arranged on the outer peripheral surface of the housing 21, and a fastener perforation is provided on the square plate 211 for bolts to pass through. Can be fixedly connected with the equipment housing. A contact piece is arranged in the housing 21, and the contact piece can be press-fitted with the printed board contact piece on the printed board 30 as a conductive compone...

Embodiment 2

[0064] Embodiment 2 of the transfer connector in the present invention: the difference from the above embodiment is that, as Image 6As shown, in the transfer connector 60 of this embodiment, the housing 61 is provided with an installation cavity and two contact pieces. A spring 63 as an elastic supporting structure is installed between the first cantilever of the two contact pieces 62 and the cavity wall of the installation cavity, and the two ends of the spring 63 support the outer surface of the contact piece 62 and the cavity wall respectively. Wherein, the cavity wall that supports and cooperates with the end of the spring 63 is a straight wall extending along the insertion direction of the transfer connector 60 , which can stably support the spring 63 .

[0065] When the contact piece 62 swings, the spring 63 can deform along with the swing of the contact piece 62 , and the spring 63 can provide a force to the contact piece 62 to press the contact piece 62 to the conduct...

Embodiment 3

[0066] Embodiment 3 of the transfer connector in the present invention: the difference from the above embodiments is that the overhanging part of the contact in this embodiment is in the shape of a line, and the overhanging part extends obliquely to the conductive component in the printed board. The extension direction of the connection end is parallel to the insertion direction, and the overhang part is inclined to lift the crimp end, so that the crimp end is closer to the conductive component; or the end of the inline overhang part is bent backward at least twice Get crimp ends that are angled or U-shaped, with the entire overhang scooped. Of course, the function of the overhanging part is to realize the swing of the contact piece, and the shape of the overhanging part can also adopt a serpentine shape or other shapes that will not affect the swinging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com