A high-voltage transmission line anti-flashover device

A technology for high-voltage transmission lines and high-voltage transmission lines, which is applied in the direction of cable suspension devices, cable installations, and mechanical vibration attenuation devices. Achieve the effects of easy replacement and maintenance, improved service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

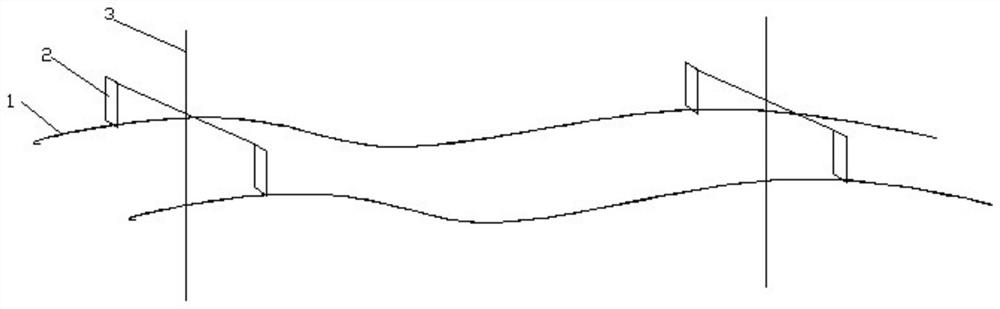

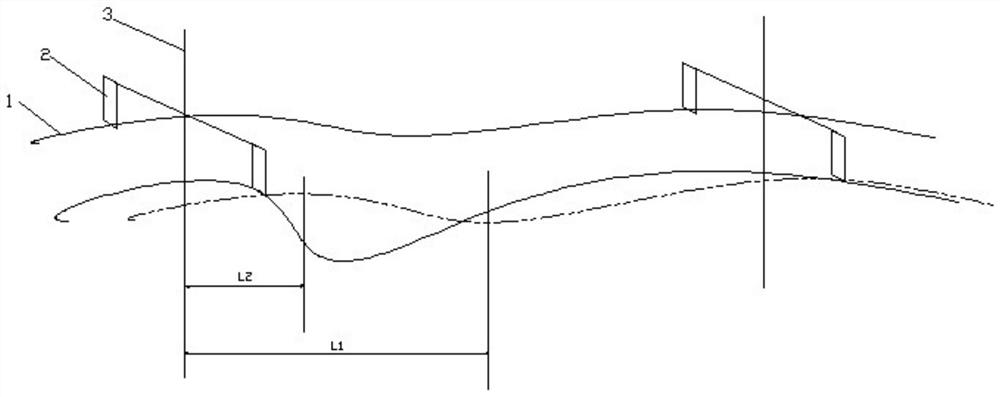

[0057] The principle of Example 1 is: shrink the length of the high-voltage transmission line between any two towers through the anti-flashover mechanism, so that it tends to be straight, that is, the length of the high-voltage transmission line tends to be equal to the distance between any two towers ; In addition, control the spacing between the high-voltage transmission line and the insulator string that shrinks to the insulator string, so that it is far away from the insulator string (that is, the tower pole in the actual state) to avoid its flashover due to the short distance.

[0058] The core idea of the realization of its mechanical structure is that when the high-voltage transmission line is pulled by the wind, the friction surface is driven to continuously rub the shape memory alloy sheet with the first length to generate heat, and after repeated friction to a certain extent (the heat generated by the friction It can be calculated by thermodynamic formulas. Differen...

Embodiment 1

[0060] The basic structure is expressed as: a high-voltage transmission line anti-flashover device, which is used to overcome the swing of the high-voltage transmission line caused by the influence of wind force on the high-voltage transmission line under the condition of strong wind.

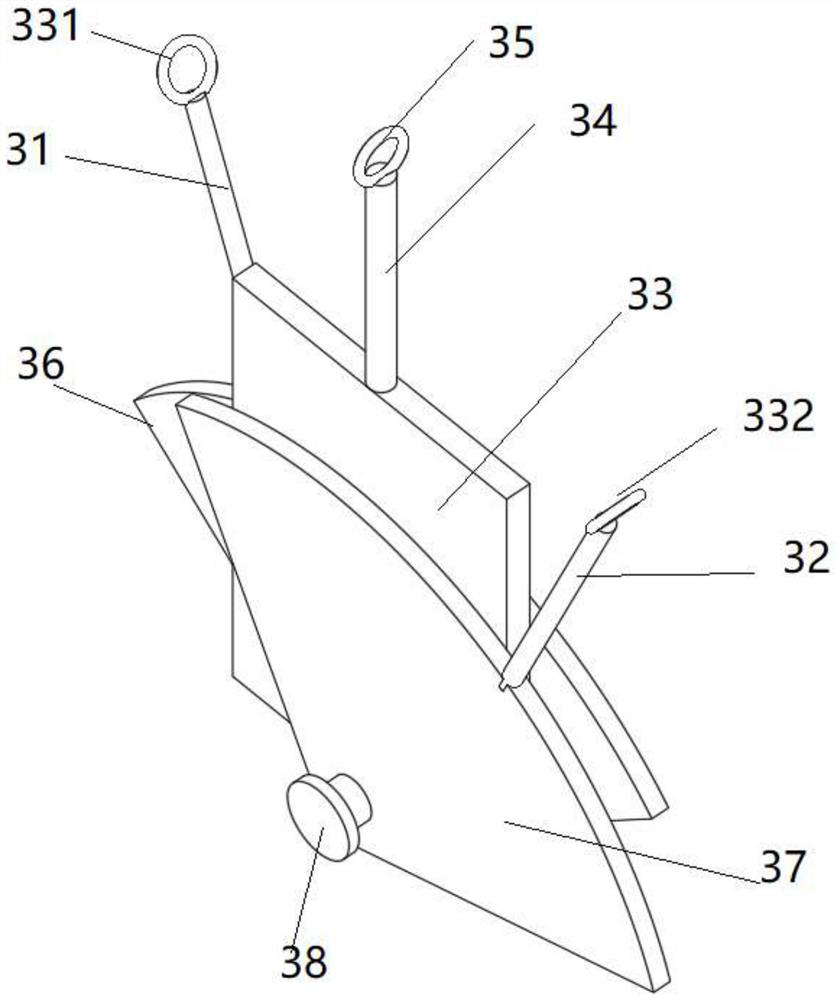

[0061] The technical solution of this embodiment is to set an anti-flashover mechanism at the end of the high-voltage transmission line insulator string, such as image 3 include,

[0062] Rotating arm one 31, supporting rod assembly and rotating arm two 32 are arranged on a fan-shaped surface with the end of the insulator string as the center of the circle, and the high-voltage transmission line passes through rotating arm one 31, supporting rod assembly and rotating arm two 32 away from the insulator The end of the string extends to both sides of the tower pole; under the action of wind, the high-voltage transmission line can drive the first rotating arm and the second rotating arm to rotate ...

Embodiment 2

[0079] The basic structure is expressed as: a high-voltage transmission line anti-flashover device, which is used to overcome the swing of the high-voltage transmission line caused by the influence of wind force on the high-voltage transmission line under the condition of strong wind.

[0080] The technical solution of the present application is to set an anti-flashover mechanism at the end of the high-voltage transmission line insulator string, such as Figure 4 shown, including,

[0081] Rotating arm one 41, supporting rod assembly and rotating arm two 42 are arranged on the parallel fan-shaped surface with the end of the insulator string as the center of the circle, and the high-voltage transmission line passes through rotating arm one 41, supporting rod assembly and rotating arm two 42 away The end of the insulator string extends to the two sides of the tower; under the action of wind, the high-voltage transmission line can drive the first rotating arm and the second rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com