Multi-chip band saw blade

A band saw blade, saw blade technology, applied in metal sawing equipment, sawing machine tools, metal processing equipment, etc. The effect of moving and compensating for wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

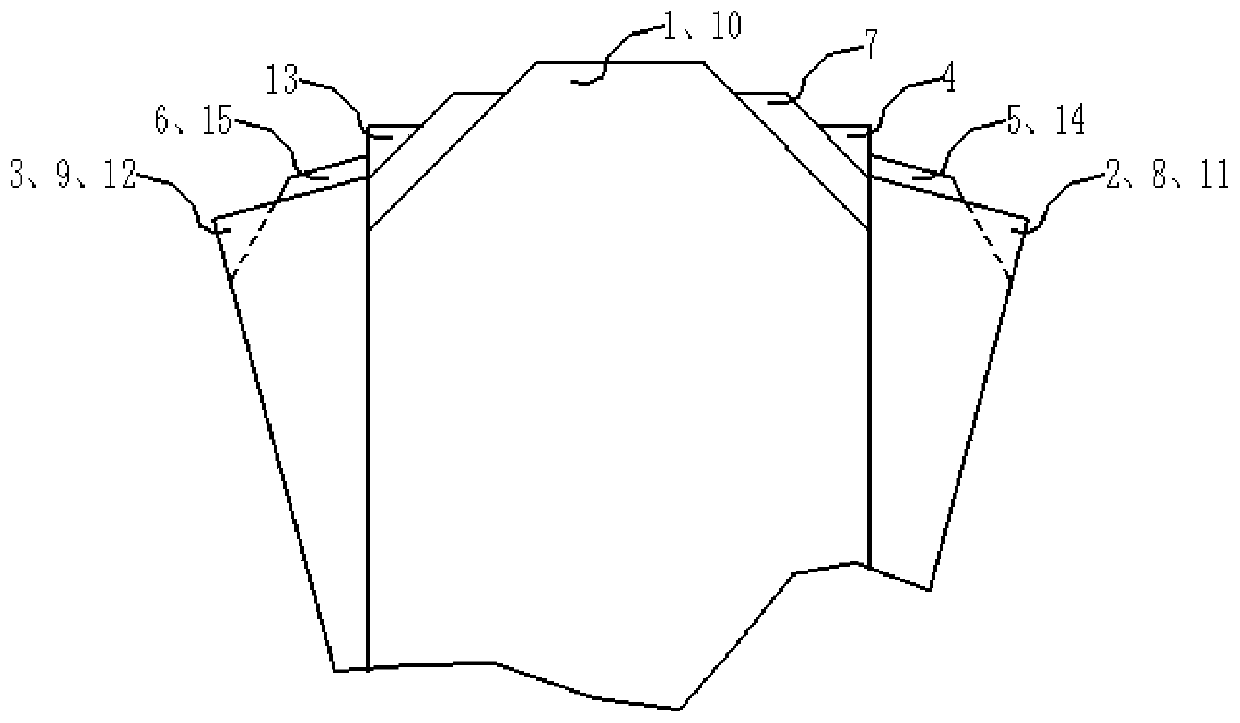

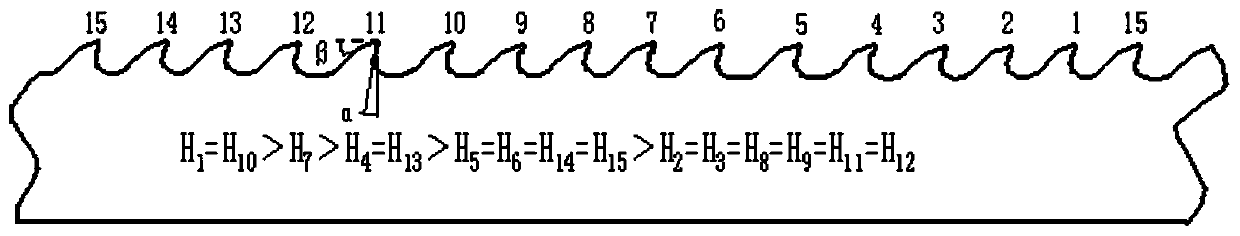

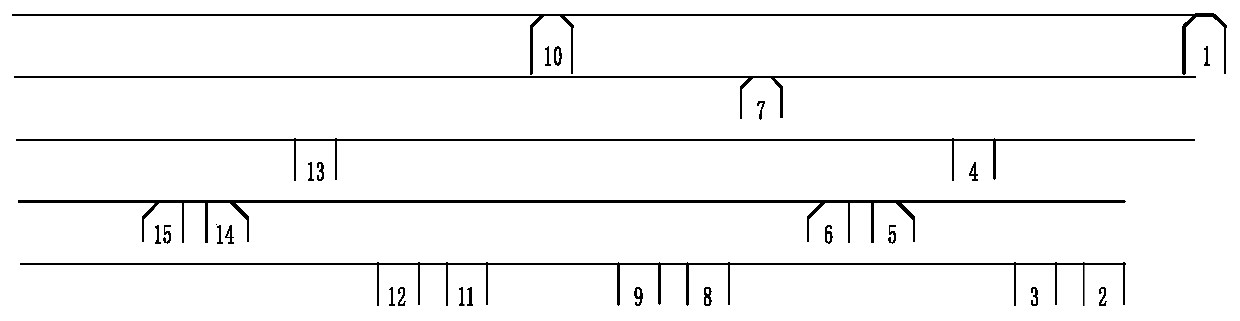

[0028] The present invention will be described in further detail below with reference to the accompanying drawings.

[0029] see Figure 1-5 , a multi-chip type band saw blade, including a saw blade body (back material) and a saw tooth located on the saw blade body, 15 saw teeth arranged in sequence form a main tooth group, each main tooth group includes a first sub-tooth group, a second Sub-tooth group, third sub-tooth group, fourth sub-tooth group, fifth sub-tooth group; each sub-tooth group includes first sawtooth, second sawtooth and third sawtooth arranged in sequence, and the first sawtooth is Straight teeth, the second and third teeth are left sub-tooth and right sub-tooth respectively; the first sub-tooth group, the second sub-tooth group, the third sub-tooth group, the fourth sub-tooth group and the fifth sub-tooth group The order of arrangement of the groups is not limited and can be arranged in any order without affecting the number or size of the chips or cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com