Pipe welding machine with welding slag cleaning function

A welding machine and welding mechanism technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency and lack of welding slag cleaning function, and achieve improved bonding effect, improved cleaning effect, and improved general-purpose sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

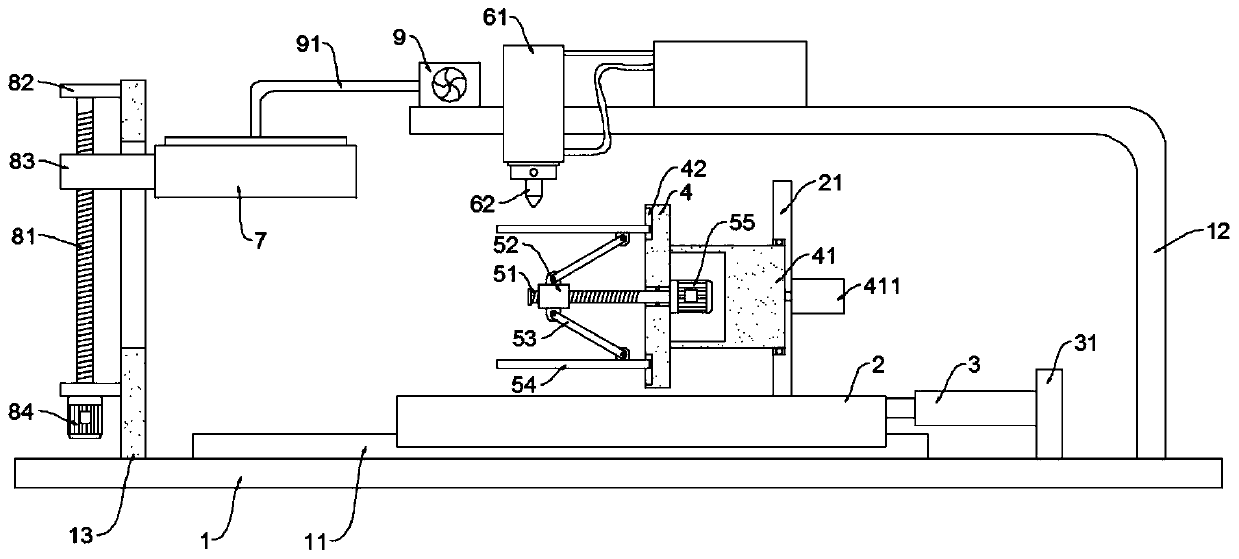

[0021] see Figure 1~3 , in an embodiment of the present invention, a pipe welding machine with the function of removing welding slag includes a base 1, a moving base 2, a rotating base 4 and a welding mechanism; the top of the base 1 is fixed with a support frame 12, and the welding mechanism is installed on On the support frame 12; the moving base 2 is slidably connected to the slide rail 11 fixed on the base 1 and driven by a traversing drive mechanism, the moving base 2 is fixed with a mounting plate 21, and the rotating base 4 is connected to the mounting plate 21 through a connecting block 41 in rotation , the connection block 41 is driven by a rotating motor 411, and a clamping mechanism is installed on the rotating seat 4. When in use, the pipe is fixed by the clamping mechanism, and then the pipe is driven by the traverse drive mechanism to move to the bottom of the welding mechanism, and then the rotating The motor 411 drives the pipe to rotate, and then the pipe is ...

Embodiment 2

[0030] see figure 1 and 4 , the embodiment of the present invention describes the clamping mechanism in detail on the basis of embodiment 1, specifically:

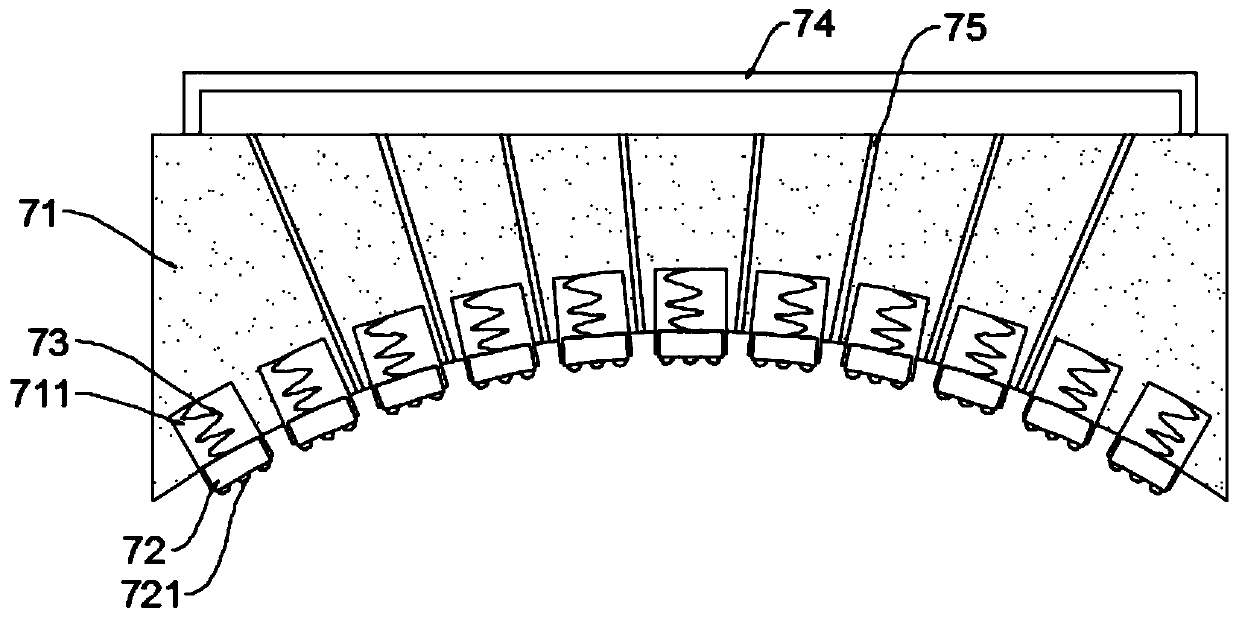

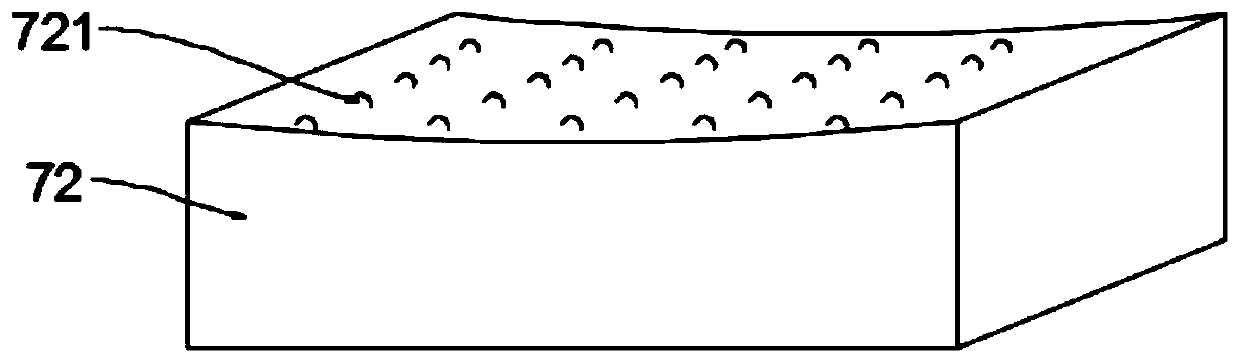

[0031] Described clamping mechanism comprises adjusting screw mandrel 51 and a plurality of ejector rods 54, and adjusting screw mandrel 51 is rotatably connected with swivel seat 4, and the adjusting motor 55 that drives adjusting screw mandrel 51 is installed on the swivel seat 4, and the rod body periphery of adjusting screw mandrel 51 A sleeve 52 matching it is sheathed; a plurality of ejector rods 54 are equidistantly arranged on the periphery of the adjusting screw rod 51 along the circumferential direction, and one end of the ejector rod 54 is slidably locked in the chute 42 opened on the rotating disk 4 Among them, a connecting rod 53 is hinged on the inner surface of the ejector rod 54, and the end of the connecting rod 53 is hinged to the sleeve 52. When working, the adjusting motor 55 drives the adjusting screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com