High-transparency polished ceramic thick plate and preparation method thereof

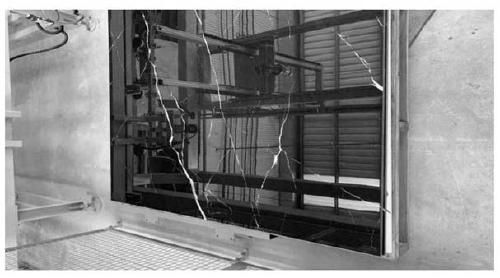

A ceramic and transparent technology, which is applied in the field of highly transparent polished ceramic thick plates and its preparation, can solve the problems of easy damage in forming and transportation, and achieve the effect of rich patterns, crystal clear texture and thick colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

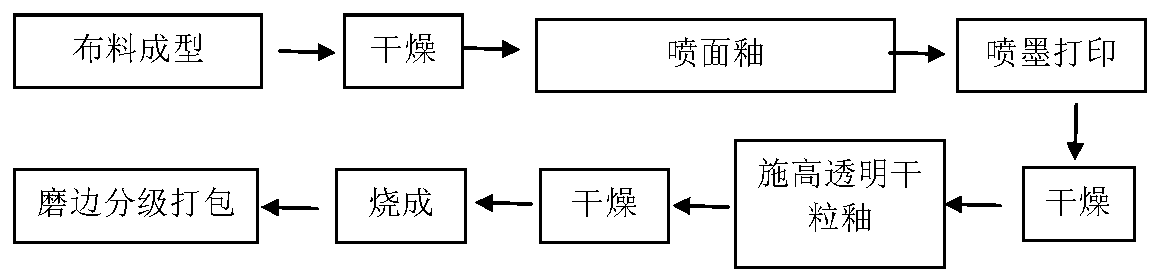

Method used

Image

Examples

Embodiment 4

[0168] Example 4 is basically the same as Example 1, except that the composition of the raw material formula of the top glaze is shown in Table 10. The raw material formula of described surface glaze is shown in Table 25.

[0169] The surface glaze formula composition unit of table 25 embodiment 4: gram

[0170]

[0171] Surface glaze chemical composition analysis of table 26 embodiment 4

[0172]

[0173] On the basis of the surface glaze formula of the original formula B, the content of silicon, aluminum, and zirconium is increased, and the firing temperature of the surface glaze is correspondingly increased, which effectively solves defects such as prickly heat and pinholes on the brick surface during the production process. question.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com