Point-suction-type facing tile for building exterior application and bonding method thereof

A decorative brick and point suction technology, which is applied in the direction of construction, building structure, covering/lining, etc., can solve the problems of long cycle, difficult construction, and large time span, so as to maintain vacuum adsorption and save preliminary preparation work. The effect of improving placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

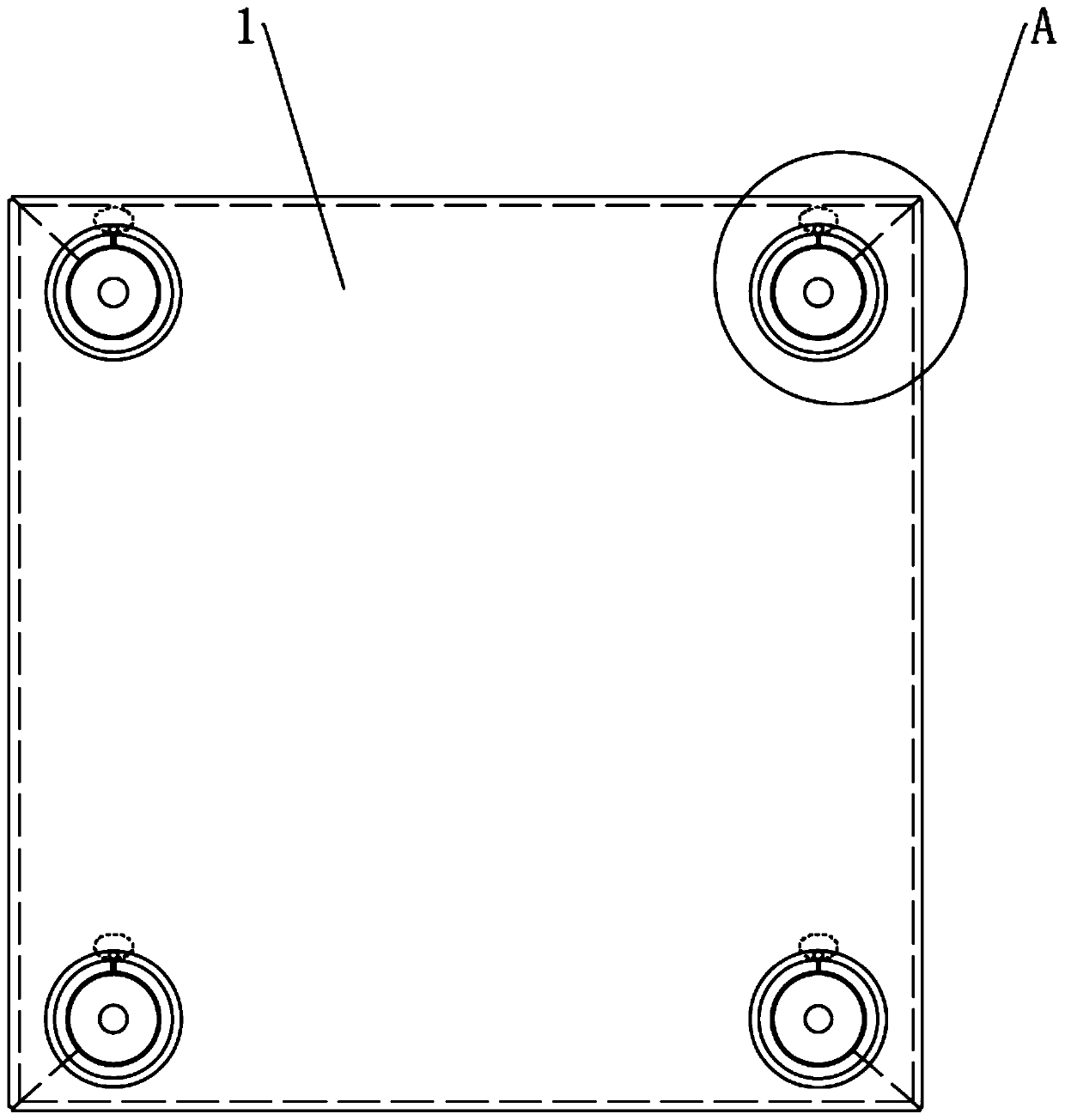

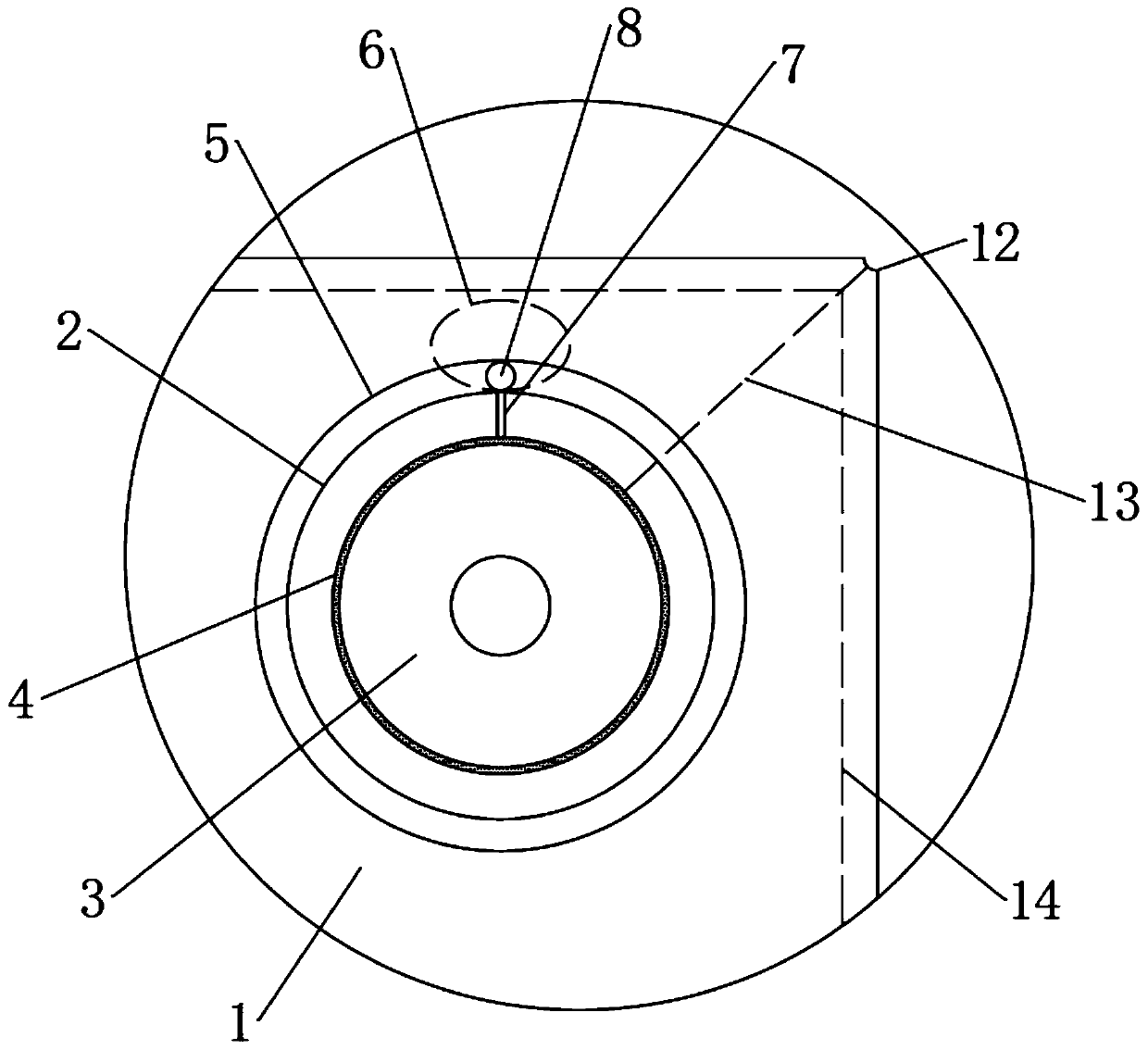

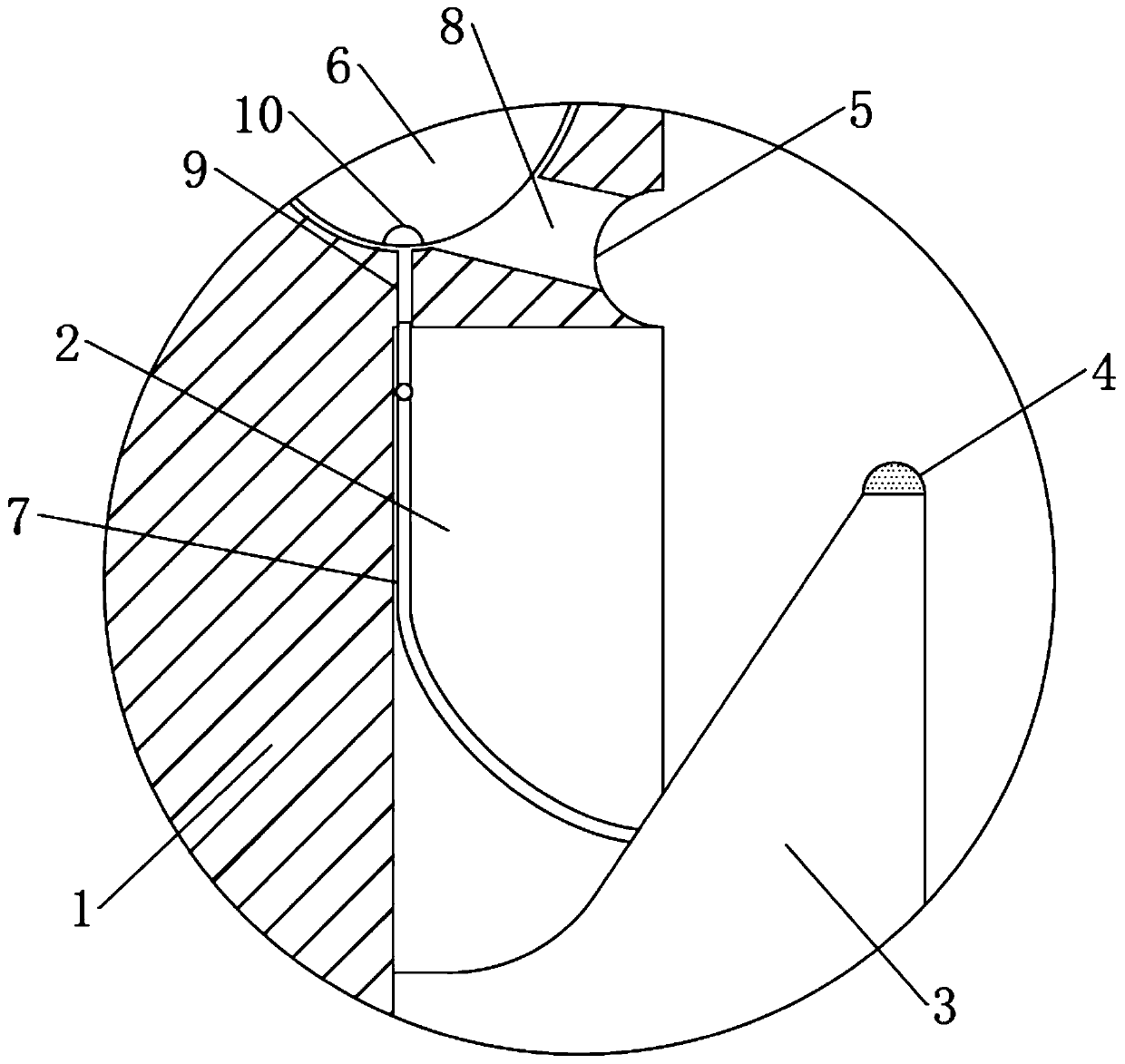

[0046] see Figure 1-4 , a point-suction decorative brick for building exterior, including a decorative brick 1, the decorative brick 1 includes a main body layer 101 and a decorative layer 102, and the end of the main body layer 101 away from the decorative layer 102 is dug with a plurality of evenly distributed adsorption grooves 2, the adsorption The bottom wall of the tank 2 is fixedly connected with a composite suction cup 3, which is used to contact and squeeze the wall and then extrude the internal air to realize vacuum adsorption, and is compressed and fixed by atmospheric pressure. The outer end of the composite suction cup 3 is fixedly connected with a water storage and wetting ring 4. The composite sucker 3 is made of silicone rubber, and anti-aging agent is added. The water storage and wetting ring 4 is made of porous sponge material. The composite sucker 3 made of silicone rubber can achieve sealing even on rough surfaces, and play a role of vacuum adsorption. fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com