Roller kiln system anomaly detection method based on exergy model

A technology of roller kiln and model, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., and can solve the problems of difficulty in building a fault knowledge system, large investment of manpower, material resources and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

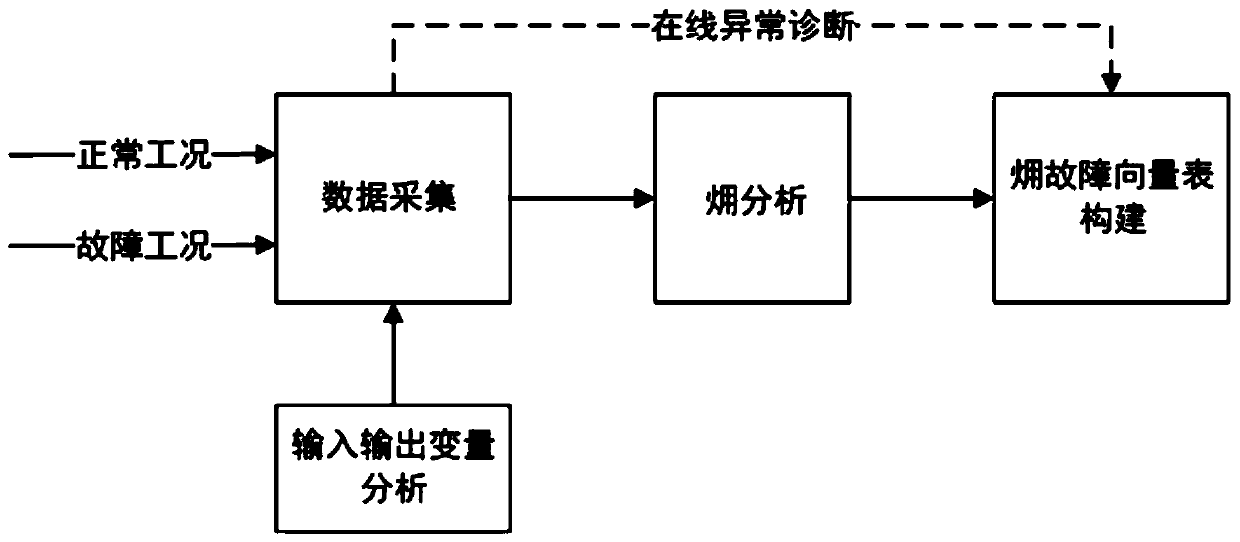

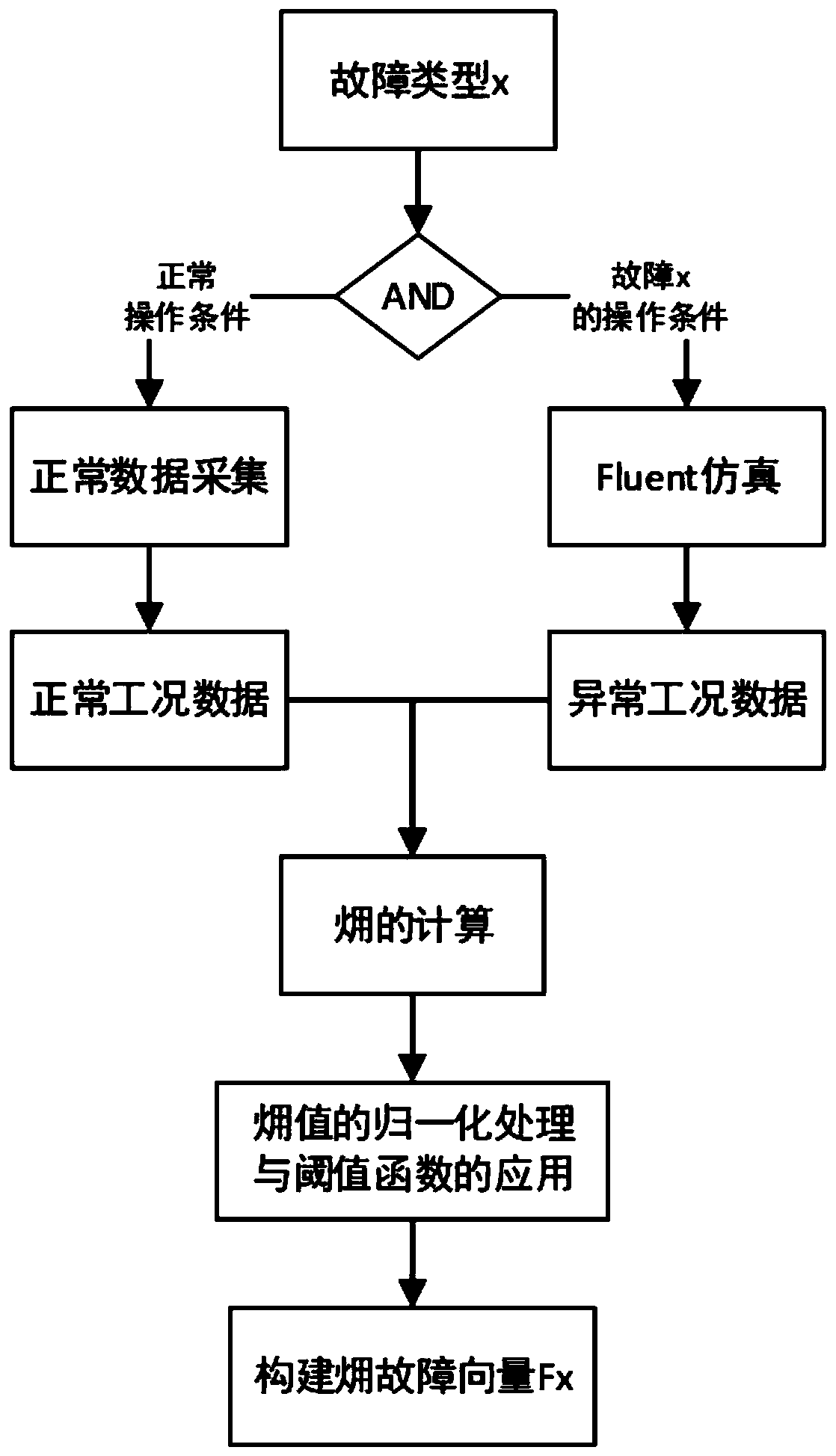

[0068] The invention discloses a The abnormal detection method of the roller kiln system of the model, first establish the roller kiln system Analysis framework, to analyze the types of faults existing in the system, through balance analysis, build The fault vector table realizes the detection and diagnosis of the faults existing in the production and operation system of the roller kiln.

[0069] Specifically, as Figure 1~4 As shown, a based on The abnormal detection method of the roller kiln system of the model includes the following steps:

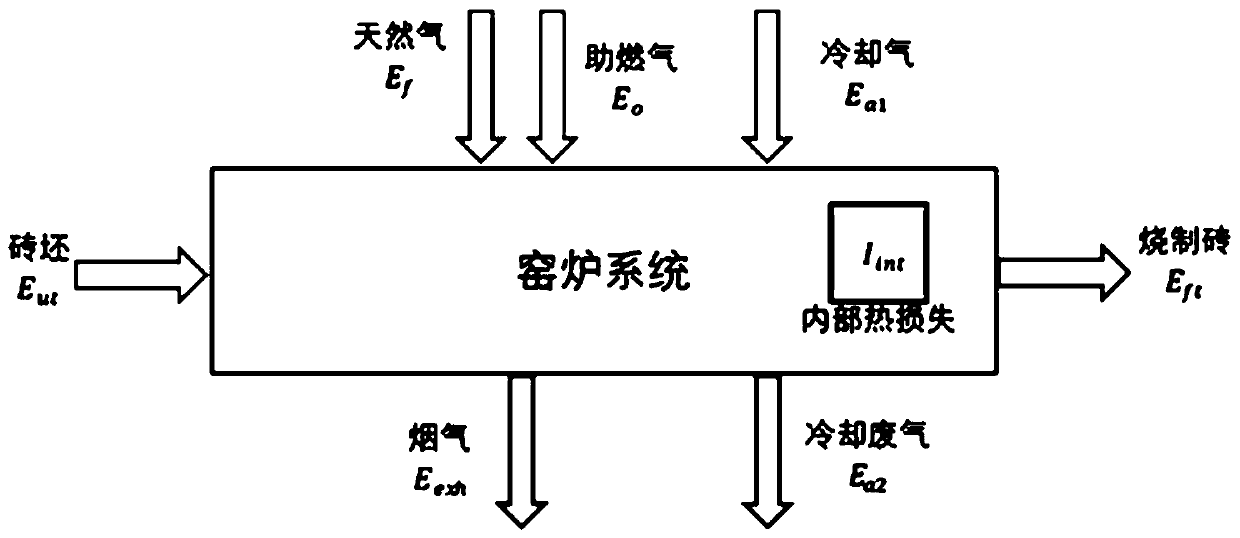

[0070] Step 1: Analysis of input and output variables; analyze the working mechanism of the roller kiln system, and obtain the input and output frame diagram of the roller kiln, as shown in figure 2 As shown, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com