A measuring tool and method for spline addendum circle diameter of disc gear

A technology of tip circle diameter and gear spline, which is applied in the field of gear addendum circle diameter measurement, can solve the problem that the measurement accuracy of odd-numbered spline addendum circle diameter cannot meet the high-precision tolerance requirements, and achieve simple structure, high precision, and accurate Measuring the effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following in conjunction with the accompanying drawings and specific embodiments of the contents of the present invention will be described in further detail.

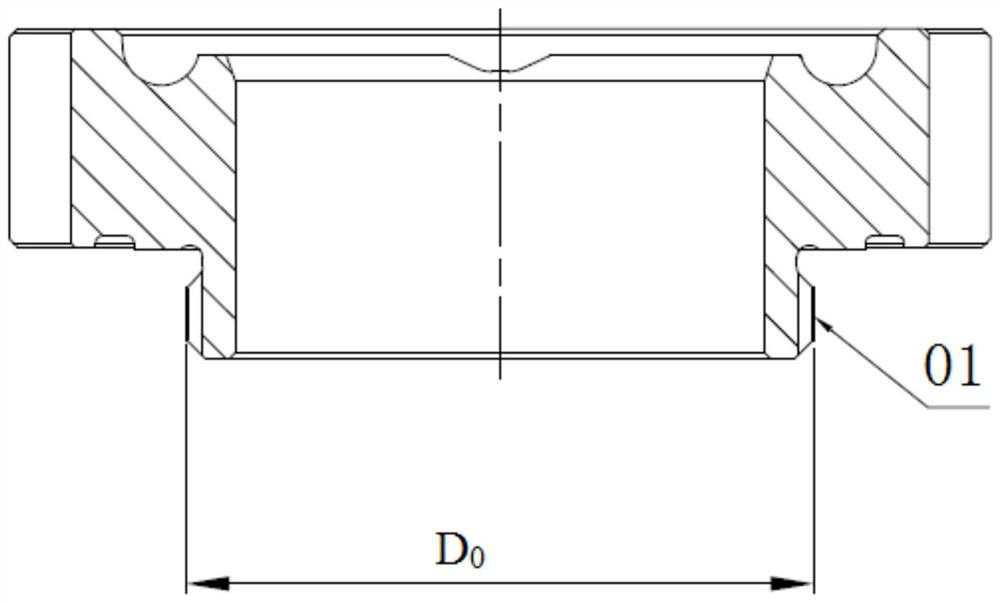

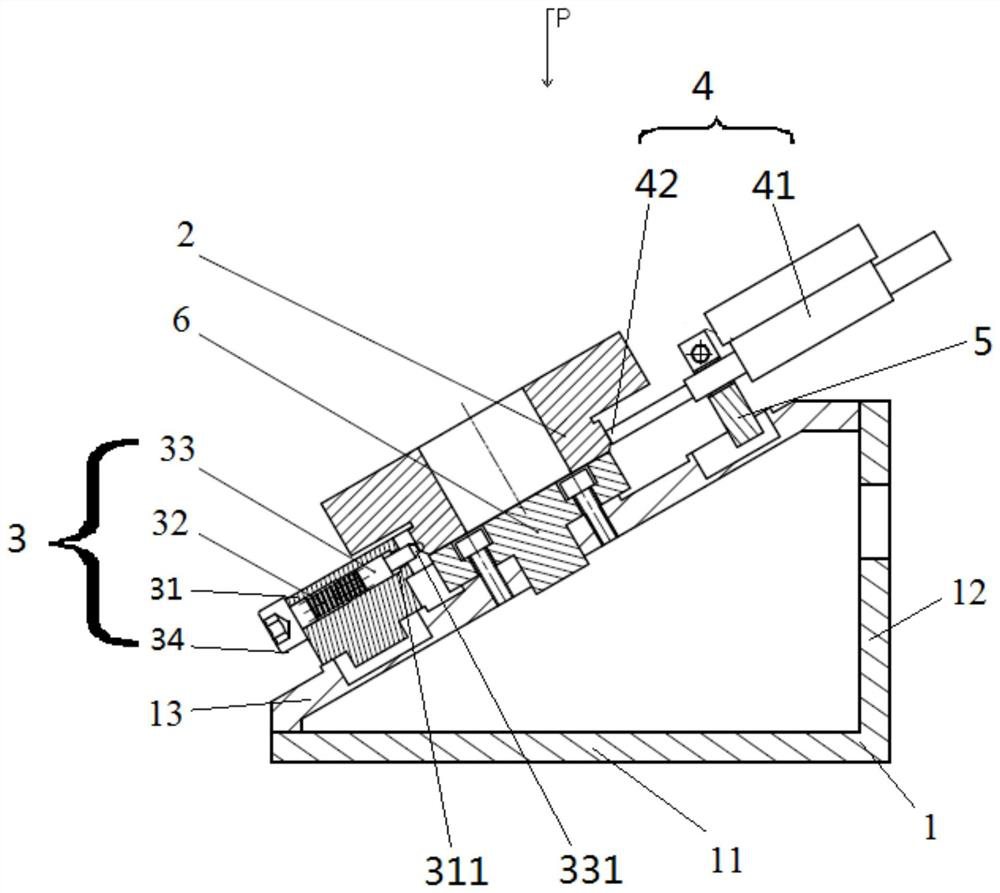

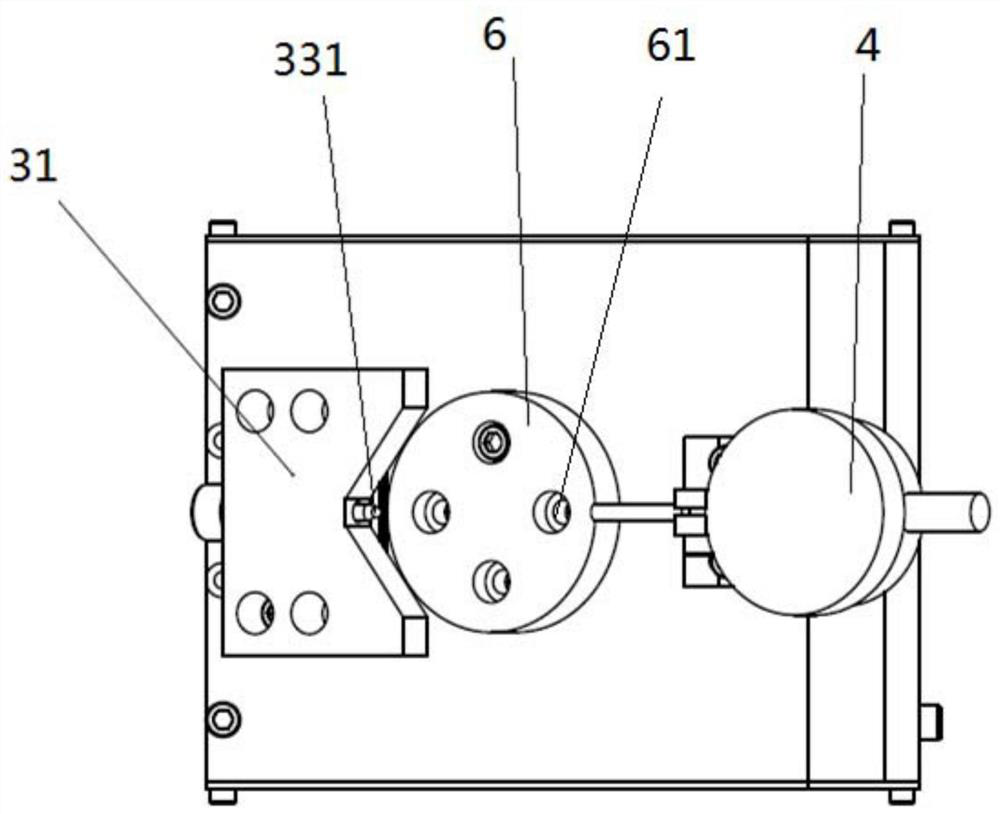

[0052] as Figures 2 through 6 As shown, a measuring instrument for the diameter of the tooth dome of the disc gear spline teeth, including the calibration block 2, the frame 1, the positioning unit 3 and the dial table 4; the proofreading block 2 is a step shaft, and the outer diameter of the small end is the same as the diameter of the tooth dome circle of the measured part; the frame 1 includes the bottom plate 11, the side plate perpendicular to the bottom plate 11 12, the inclined plate connecting the bottom plate 11 and the side plate 12 13, the angle between the bottom plate 11 and the inclined plate 13 is 20 ° ~ 35 ° is appropriate, and the positioning platform 6 is installed on the inclined plate 13. The upper end of the positioning platform 6 is parallel to the upper surface of the inclined plate 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com