Space closed type flexible precise adjusting device and assembling method thereof

A technology of precise adjustment and assembly method, applied in the field of aerospace optical remote sensors, can solve the problems of difficult to improve the structural rigidity, complex configuration of the six-degree-of-freedom mechanism, difficult control, etc. Rail environment requirements, the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

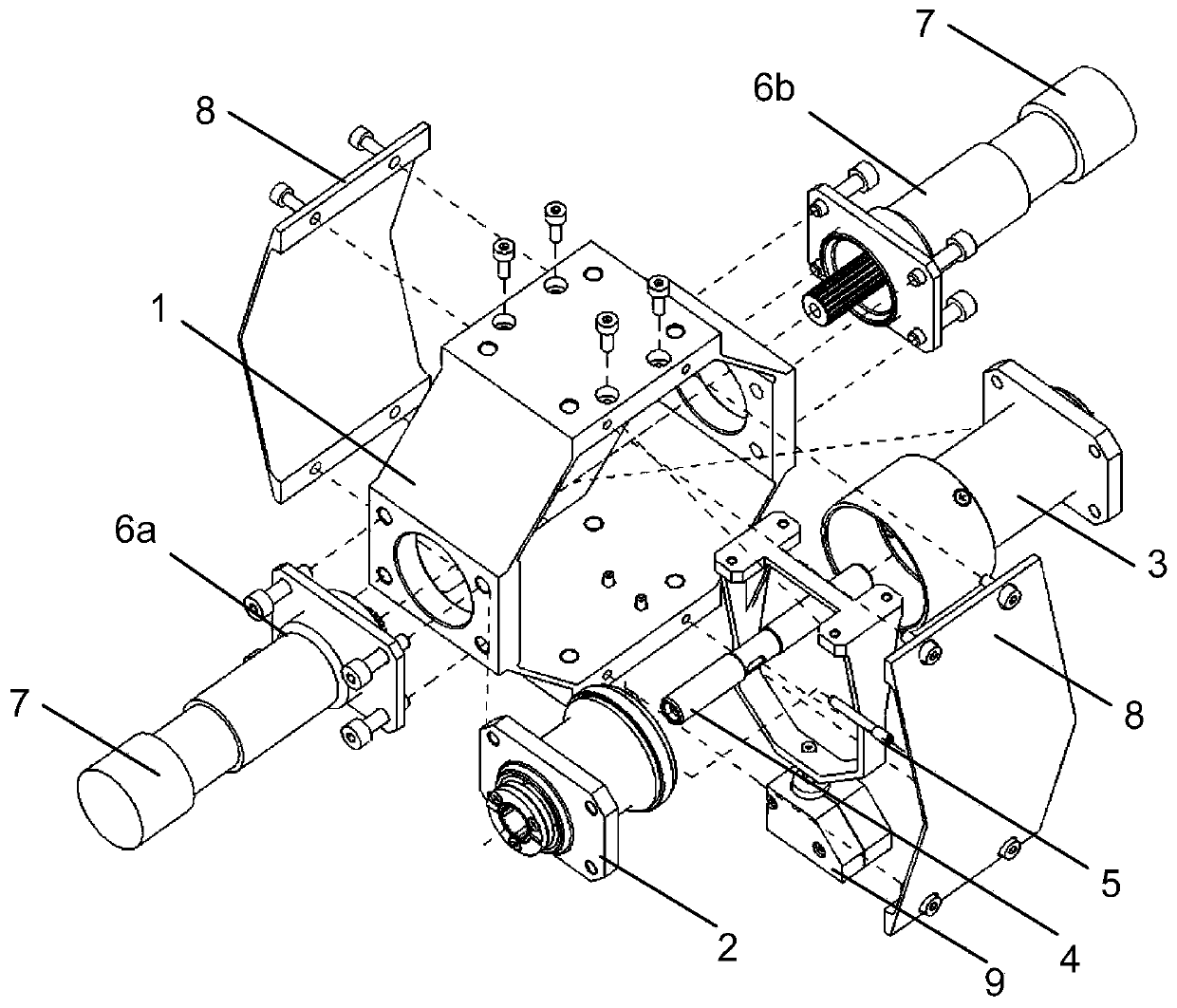

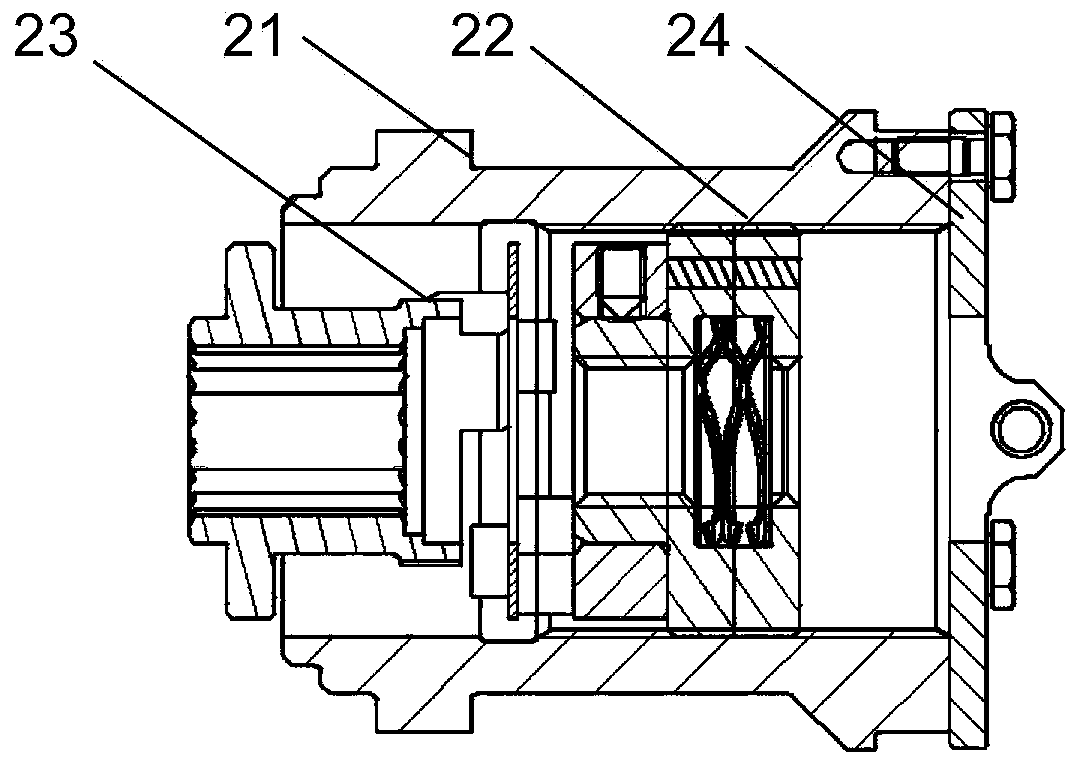

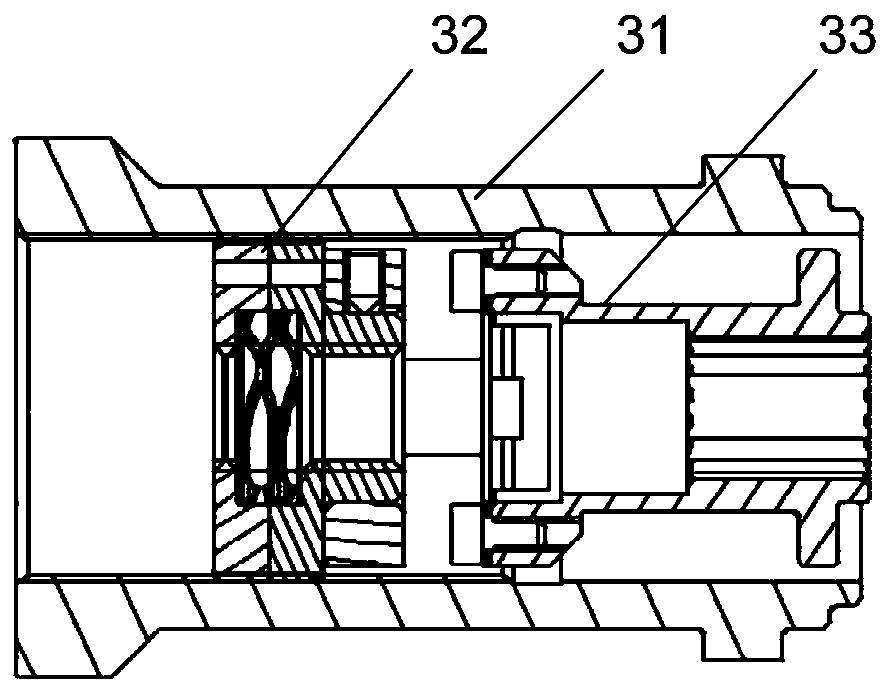

[0047] A space-enclosed flexible precision adjustment device of the present invention comprises a diamond-shaped elastic structure (1), a screw assembly 1 (2), a screw assembly 2 (3), a translation screw (4), a limit stud (5), a motor Assembly (6), angular displacement sensor (7), torsion support (8) and linear displacement sensor assembly (9). The closed flexible precision adjusting device of the present invention achieves submicron-level high precision and good self-locking performance through the transmission design of the differential screw, and at the same time transmits the displacement through the diamond-shaped elastic structure (1); through the anti-torsion support (8) The torsion resistance of the device is greatly improved. The assembly method of the present invention plays an important role in ensuring the performance of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com