Oil-air lubricating casting crystallizer

A casting mold, oil and gas technology, applied in the field of foundry equipment, can solve the problems affecting the quality of the ingot, bubble overflow, short service time of the graphite ring, etc., and achieve the effects of preventing ingot defects, improving service life, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

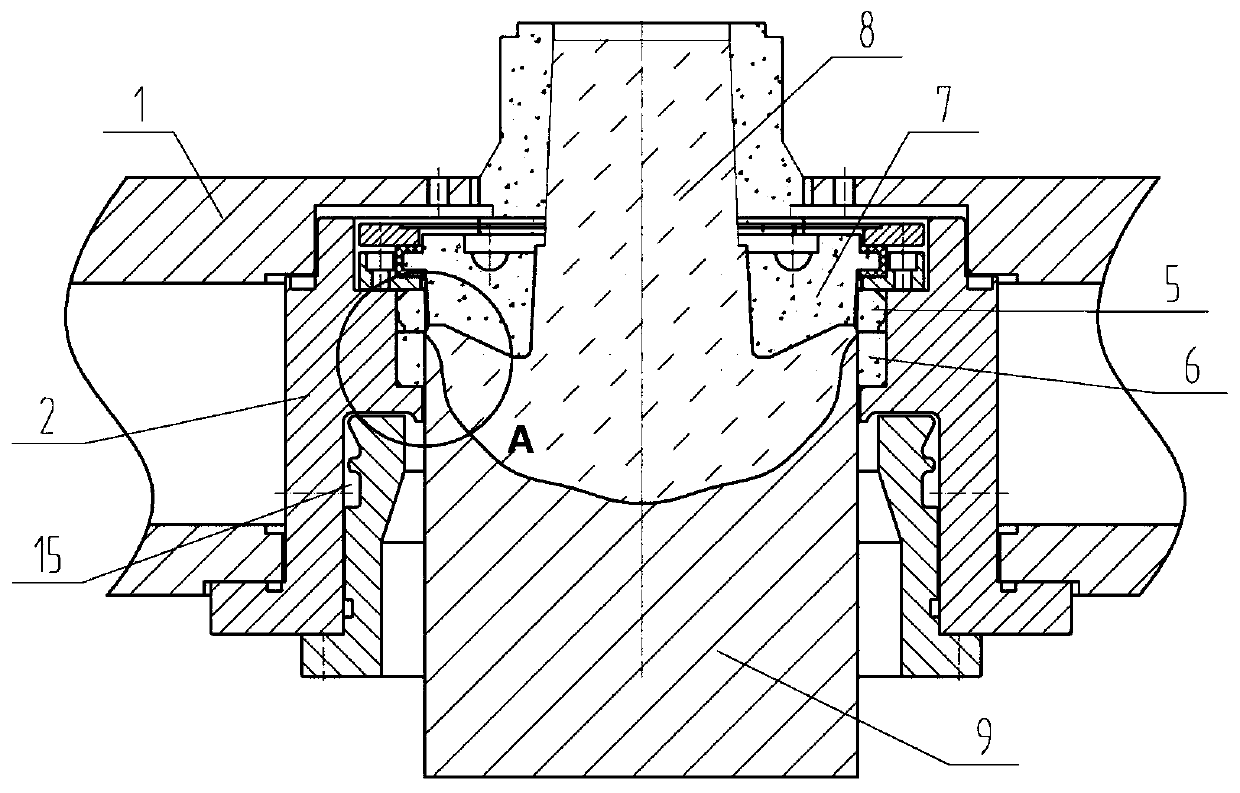

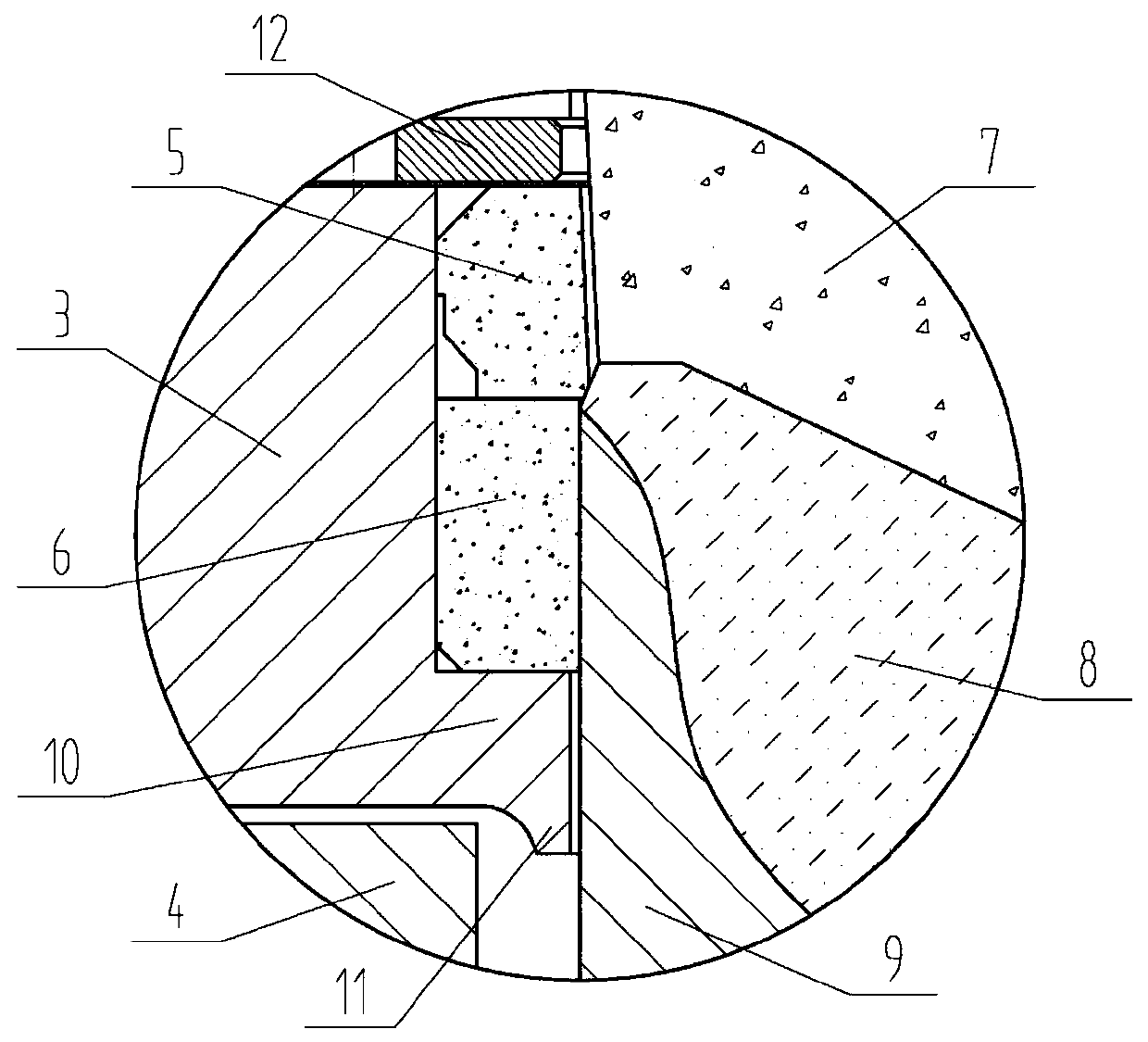

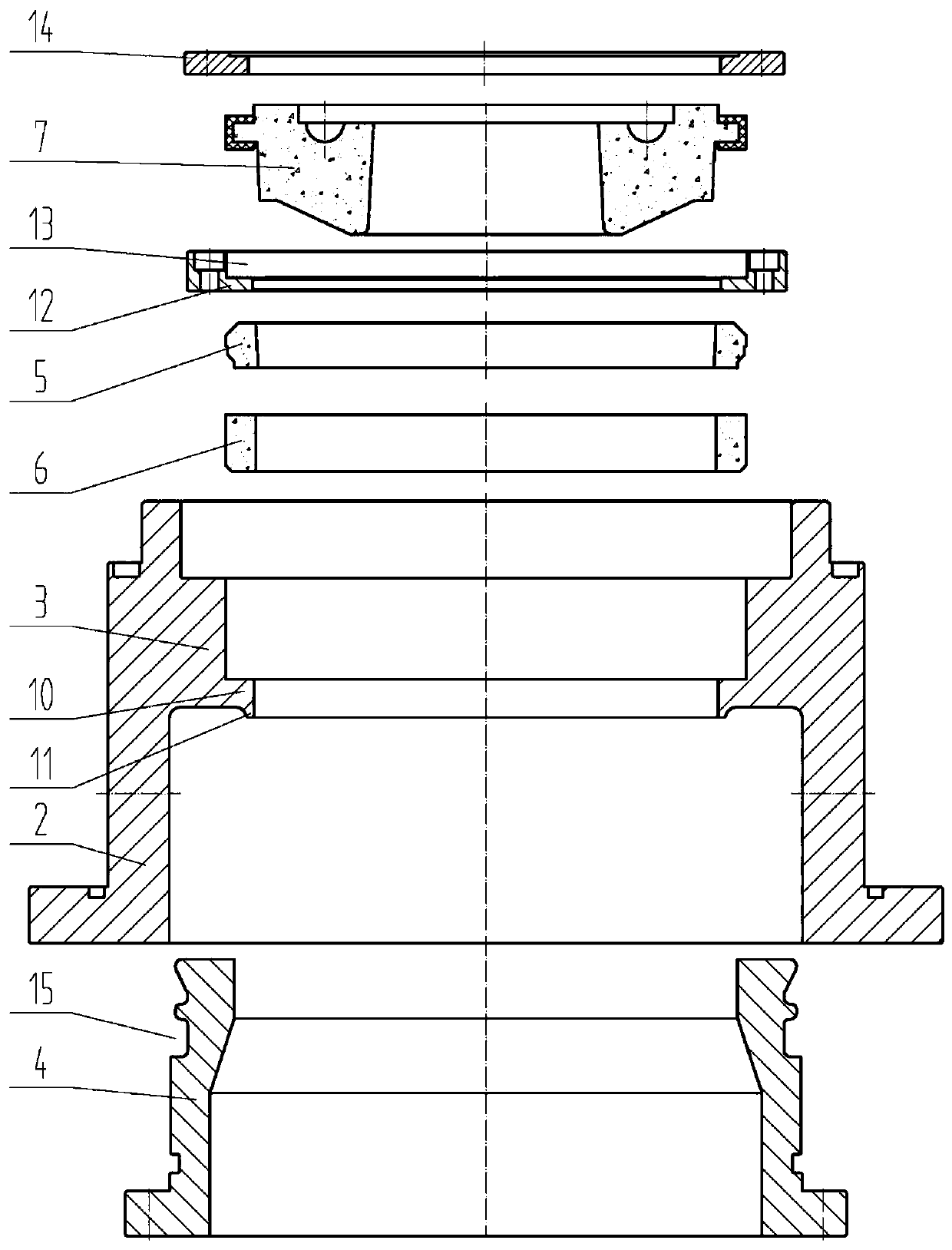

[0022] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Depend on Figure 1 to Figure 3 It can be known that an oil-gas lubricating casting crystallizer includes an outer jacket 2 embedded in the box body 1, a through hole is provided inside the outer jacket 2, a step 3 is provided in the middle of the through hole, and an inner sleeve 4 is connected to the inner sleeve 4 at the lower end of the through hole. Graphite ring 1 5 and graphite ring 2 6 are embedded in sequence at the step 3, and a positioning ring 10 is provided at the lower end of the step 3, and the graphite ring 2 6 is in contact with the positioning ring 10, and the lower end of the positioning ring 10 protrudes from the barb close to the aluminum rod 9 11. The top of the inner sleeve 4 is higher than the barb 11, the inner sleeve 4 is inserted into the outer sleeve 2 from the lower end of the outer sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com