Full-automatic nut machining device

A processing device, fully automatic technology, applied in the direction of automatic in/out of workpiece, positioning device, tangent device, etc., can solve the problems of time-consuming loading, low efficiency, and time-consuming, etc., and achieve saving Manufacturing cost, easy to use, novel design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

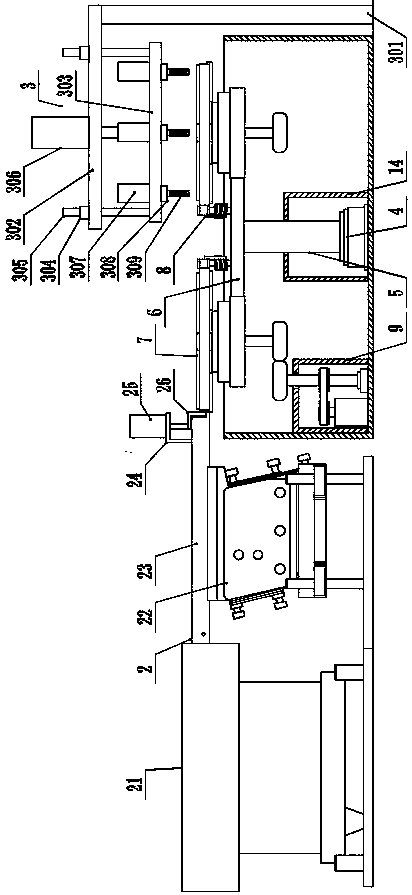

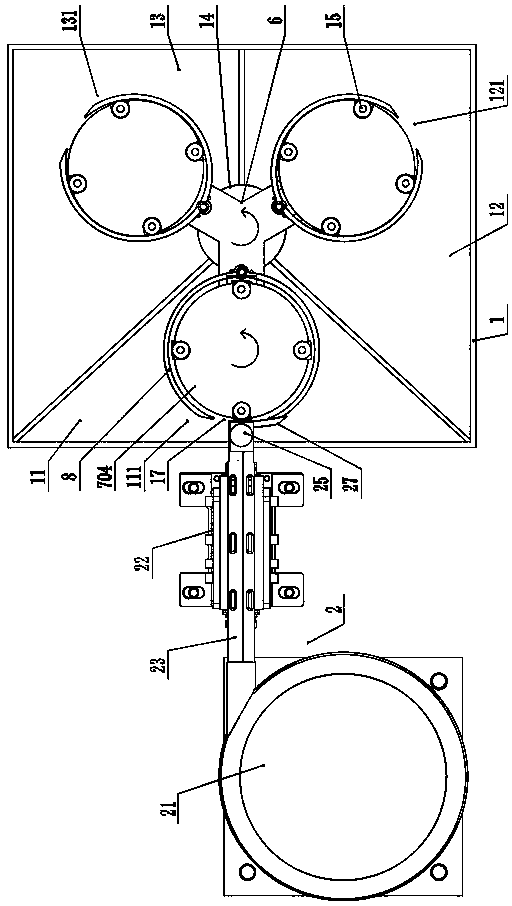

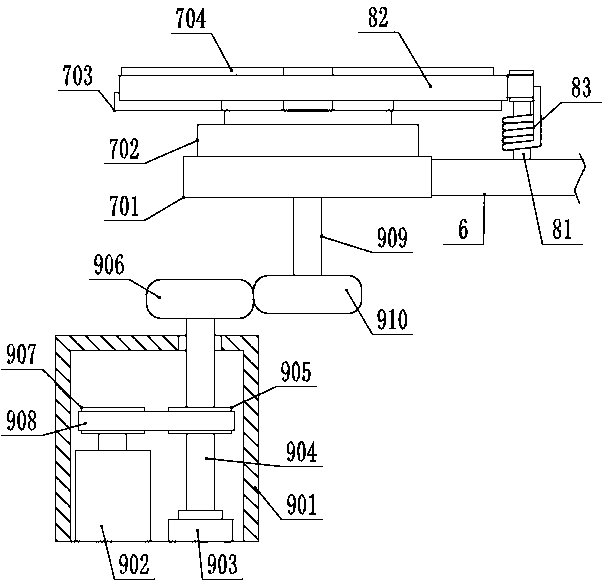

[0040] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-15 Shown: a kind of full-automatic nut processing device, comprises frame 1, feeding mechanism 2 and tapping mechanism 3, is provided with nut feeding chamber 11, nut tapping chamber 12 and nut unloading chamber 13 in frame 1, nut The feeding chamber 11, the nut tapping chamber 12 and the nut unloading chamber 13 respectively have a feeding station 111, a tapping station 121 and a blanking station 131, and the output end of the feeding mechanism 2 extends to the feeding station 111, A first protective shell 14 is fixed inside the frame 1, and a rotary table 4 is installed in the first protective shell 14. A rotating shaft 5 is vertically installed on the rotating end surface of the rotary table 4, and the upper end of the rotating shaft 5 protrudes from the first protective shell 14. And a rotating frame 6 is fixed, and the rotating frame 6 is trident-shaped and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com