Tool for assembling and welding telescopic arm forklift frame

A technology for fork loader and telescopic boom, which is applied to auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of large concentricity and hole spacing errors, low production efficiency, and high labor-hour consumption, so as to ensure interchangeability and improve Production efficiency, the effect of reducing the difficulty of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

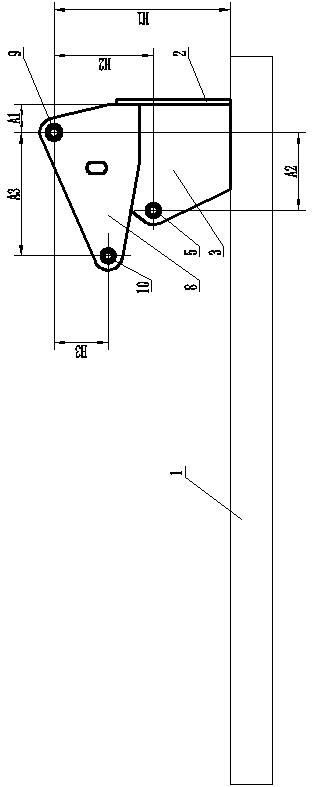

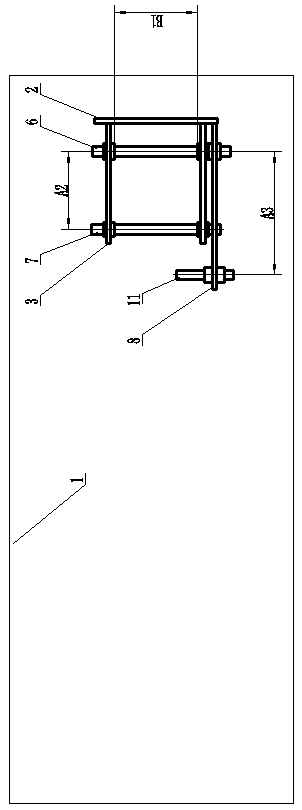

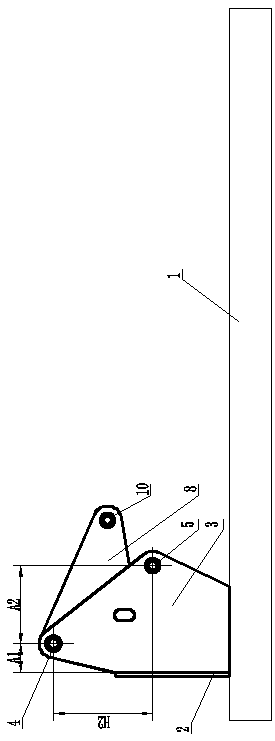

[0023] Such as Figure 1 to Figure 6 As shown, a telescopic forklift truck frame welding tooling of the present invention includes a welding platform 1, on which a support plate assembly for supporting and positioning the forklift truck frame 12 is arranged, and the support plate assembly includes a vertical plate 2 And two inner splints 3 symmetrically arranged and used to clamp the forklift truck frame 12, the vertical plate 2 is vertically fixed on the welding platform 1, and the two inner splints 3 are fixedly connected to the vertical plate 2 and are perpendicular to the vertical plate 2 , the inner splint 3 is provided with a main positioning hole 4 for positioning the bushing hole of the main pivot point and a second positioning hole 5 for positioning the bushing hole of the luffing cylinder seat, and the main positioning hole 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com