Integrated control valve block for power gear shifting gearbox

A power shift and gearbox technology, applied in the field of integrated control valve blocks, can solve the problems of not meeting the space matching requirements of the torque converter and the box body, high production cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

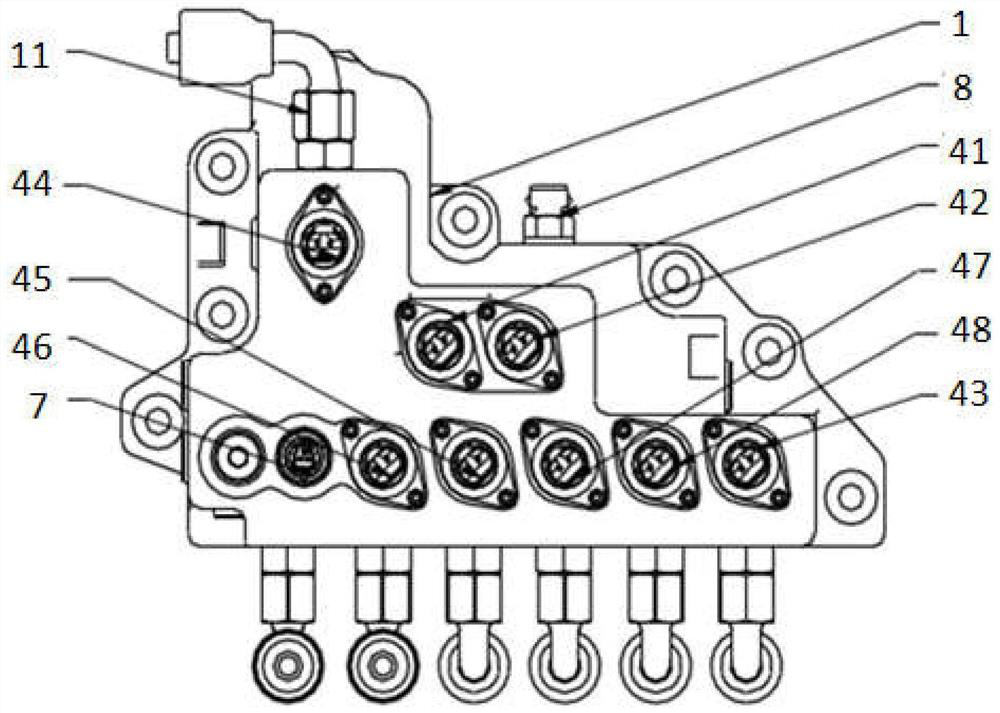

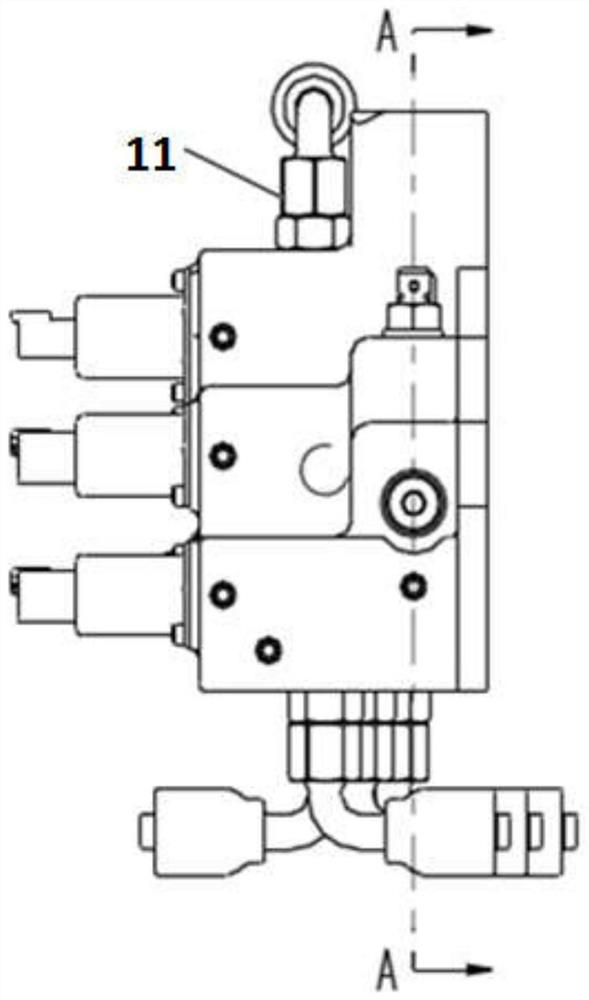

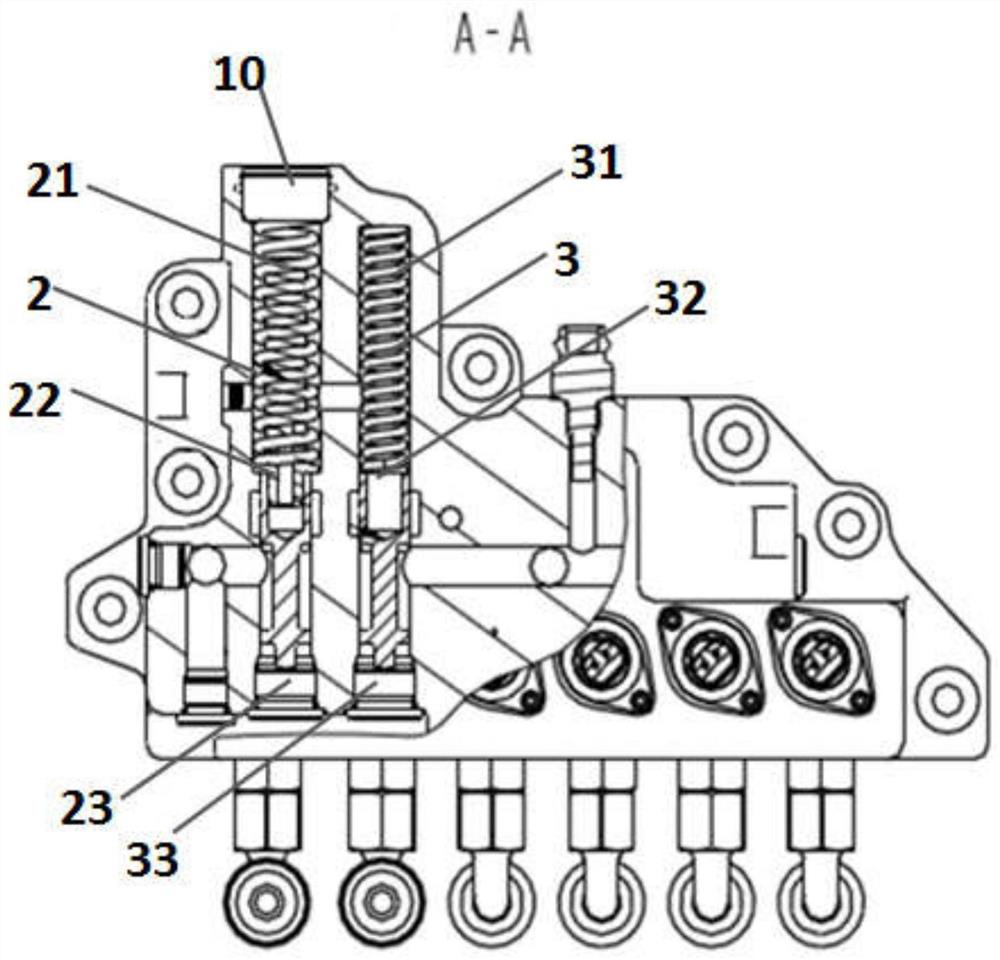

[0026] The embodiment of the present invention provides an integrated control valve block for a power shift gearbox, including a valve body 1. The valve body 1 is provided with a main pressure regulating valve 2 and a back pressure valve 3, and the valve body 1 is also provided with a solenoid valve for mounting There are eight cavity holes of the valve, and each cavity hole is correspondingly connected with a solenoid valve, and the eight solenoid valves are arranged perpendicular to the main regulating valve 2. One of the solenoid valves is used to control the lock-up clutch oil port 401 (for ease of description, hereafter referred to as the lock-up solenoid valve 41), the remaining seven solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com