Welding deformation control process used for manufacturing plug type hoisting platform pile leg

A lifting platform, welding deformation technology, applied in welding equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of easy deformation of welding, difficult to ensure the high precision of the overall size, etc., to avoid welding deformation, strengthen structural rigidity, not easy to deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

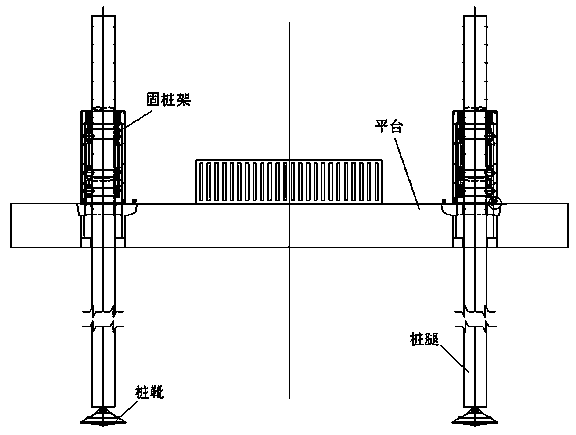

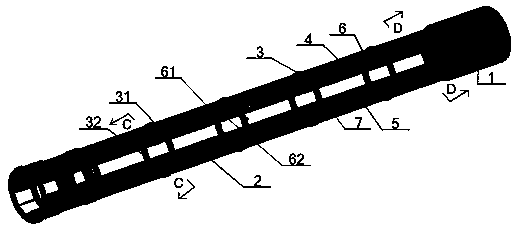

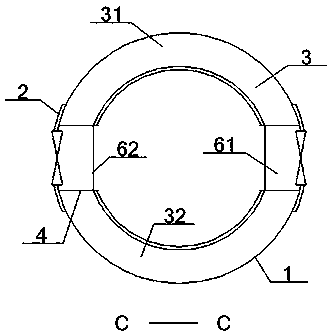

[0064] see figure 2 – Figure 11 , used for the welding deformation control process of the bolt-type lifting platform pile legs, the pile legs include an outer cylinder 1, a pasting plate 2, a ring rib 3, a long longitudinal rib 4, a pin hole 5 and a pin box 6; The interior of the cylinder 1 is provided with long longitudinal ribs 4, ring ribs 3, and latch boxes 6. The number of the long longitudinal ribs 4 is four, and the long longitudinal ribs 4 are arranged symmetrically with respect to the central axis of the cylinder 1. , every two long longitudinal ribs 4 form a group, a plurality of latch boxes 6 are clamped between the inner walls of the two long longitudinal ribs 4 in each group, and the outer walls of the two long longitudinal ribs 4 in each group are respectively connected There are upper ring ribs 31 and lower ring ribs 32 to form a whole ring rib 3. The ring ribs 3 are arranged at intervals along the distribution sequence of the latch box 6. The latch box 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com