Flexible expansion device and manufacturing method thereof

The technology of an expansion device and a manufacturing method, which is applied in the field of musical instruments, can solve the problems of poor sealing of the end of the flexible expansion device, the locking force cannot be too large, and the locking force is difficult to grasp, etc., and achieves light weight and large expansion force. , make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

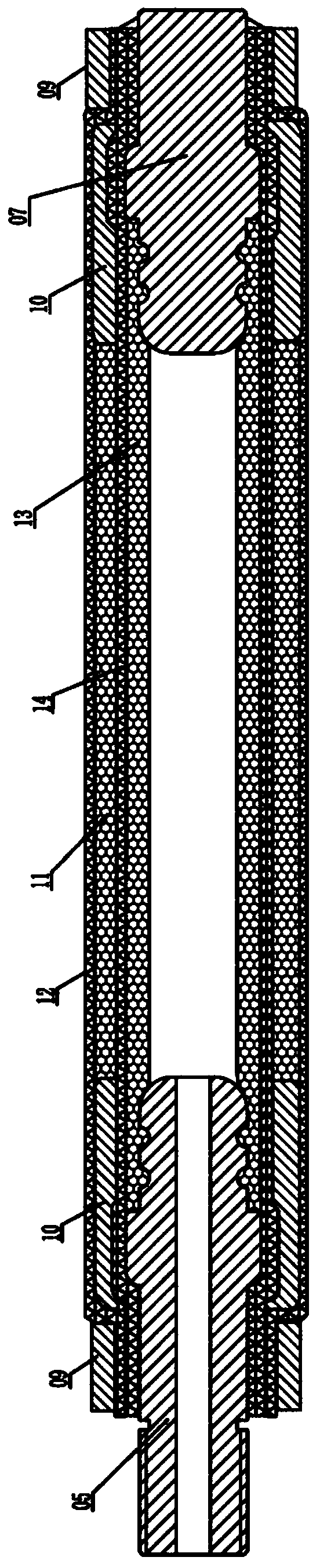

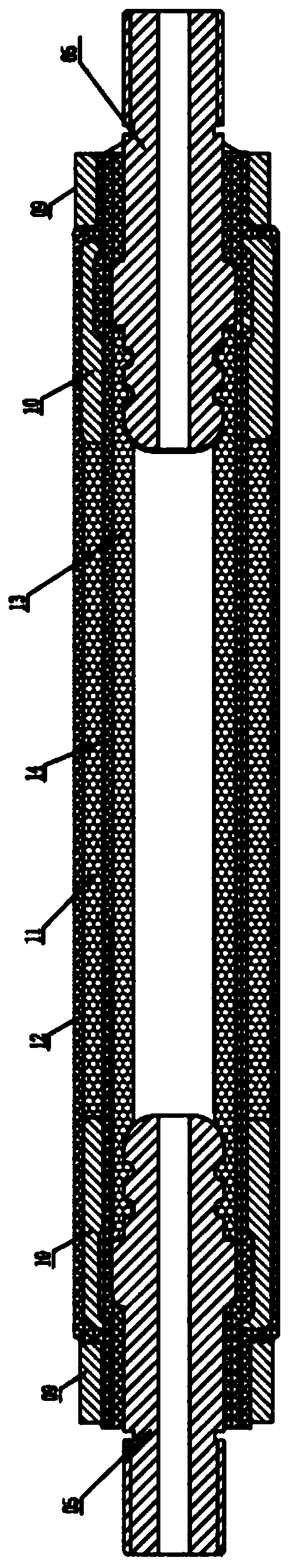

[0057] Embodiment one: if figure 1 , image 3 and Figure 4 As shown, the flexible expansion device of the present invention includes a connecting body 05 that cooperates with the external connection, a plugging head 07, a locking sleeve 09, a compression sleeve 10, a stabilizing layer 11, and an anti-wear layer (that is, a wear-resistant layer) 12 , the inner bag 13, the pressure-bearing layer 14, etc., wherein the plugging head 07 can be replaced with a connecting body 05 to realize the serial connection of multiple flexible expansion devices.

[0058] Both ends of the inner bag 13 are open, and the material of the inner bag 13 can be nitrile rubber, thermoplastic elastomer, casting rubber and plastic material, and the casting rubber and plastic material includes polyurethane, polyol resin or polyether polyurethane.

[0059] The pressure-bearing layer 14 is woven from aramid fiber, carbon fiber, ultra-strong molecular weight polyethylene fiber, glass fiber or metal fiber. ...

Embodiment 2

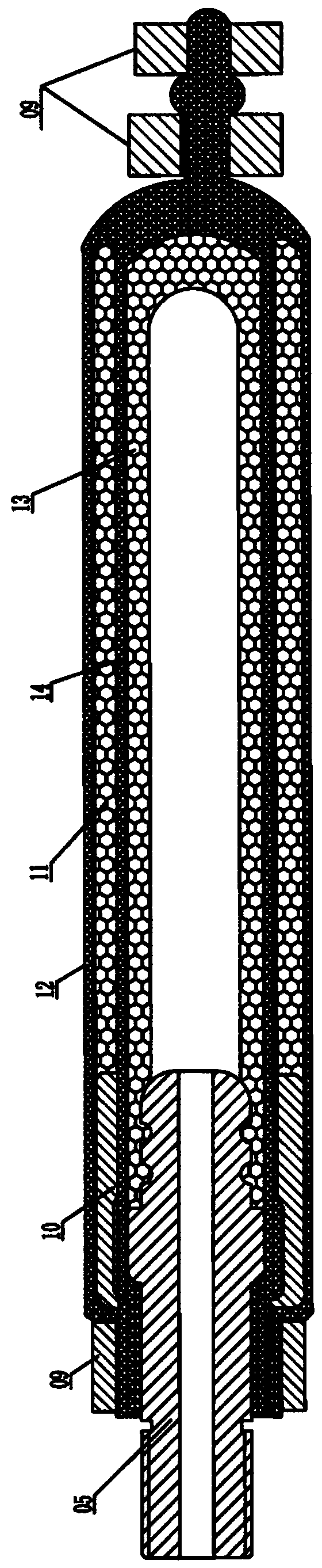

[0135] Embodiment two: if figure 2 As shown, the flexible expansion device of the present invention includes a connecting body 05 that cooperates with the external connection, a locking sleeve 09, a compression sleeve 10, a stable layer 11, an anti-wear layer 12, an inner bag 13, a pressure-bearing layer 14, and the like.

[0136] One end of the inner bag 13 is opened and connected to the connecting body 05, and the other end is blocked to form a blind end. The blind end of the inner bag 13 does not use a connecting part, but uses a locking sleeve 09 to lock the wear-resistant layer 12 and the pressure-bearing layer 14 to form an internally closed end surface to seal the inner bag 13 .

[0137] The inner bag 13 with blind end adopts pouring method to make, as Figure 13 As shown, the specific steps of the pouring method are as follows:

[0138] 1) Assemble the feed end cap 22 to one end of the mold body 21;

[0139] 2) Assemble the bracket end cover 20 to the other end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com