A coating line automatic transfer machine equipment

A transfer machine and coating line technology, applied in spraying devices, conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, low flexibility, and influence on production progress, so as to reduce floor space and increase Flexibility and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]In order to make the above objects, features, and advantages of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It is to be noted that the appended claims Non-accurate comparisons are used in the accompanying forms of the present invention.

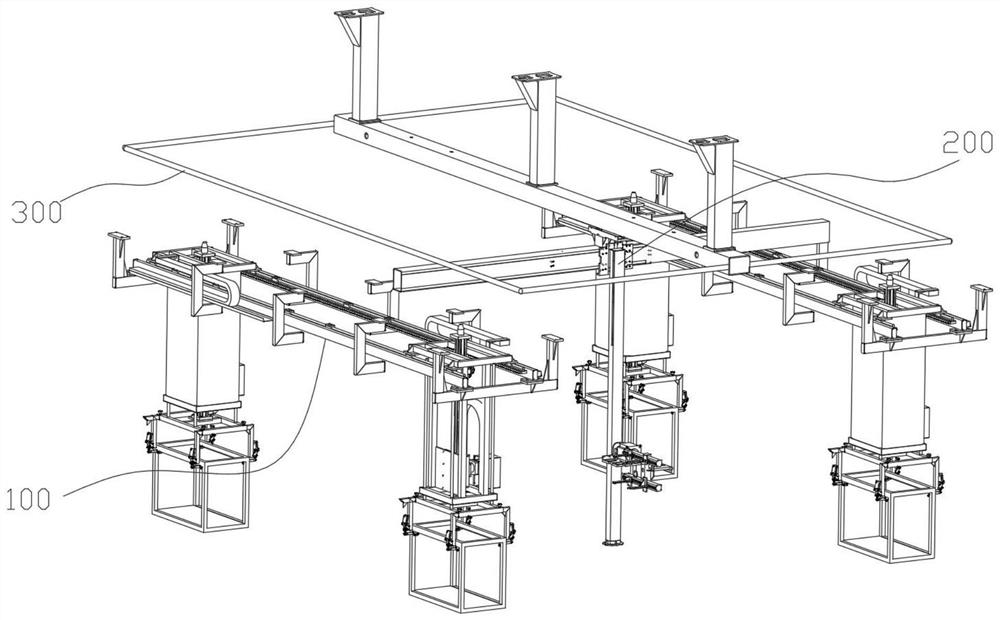

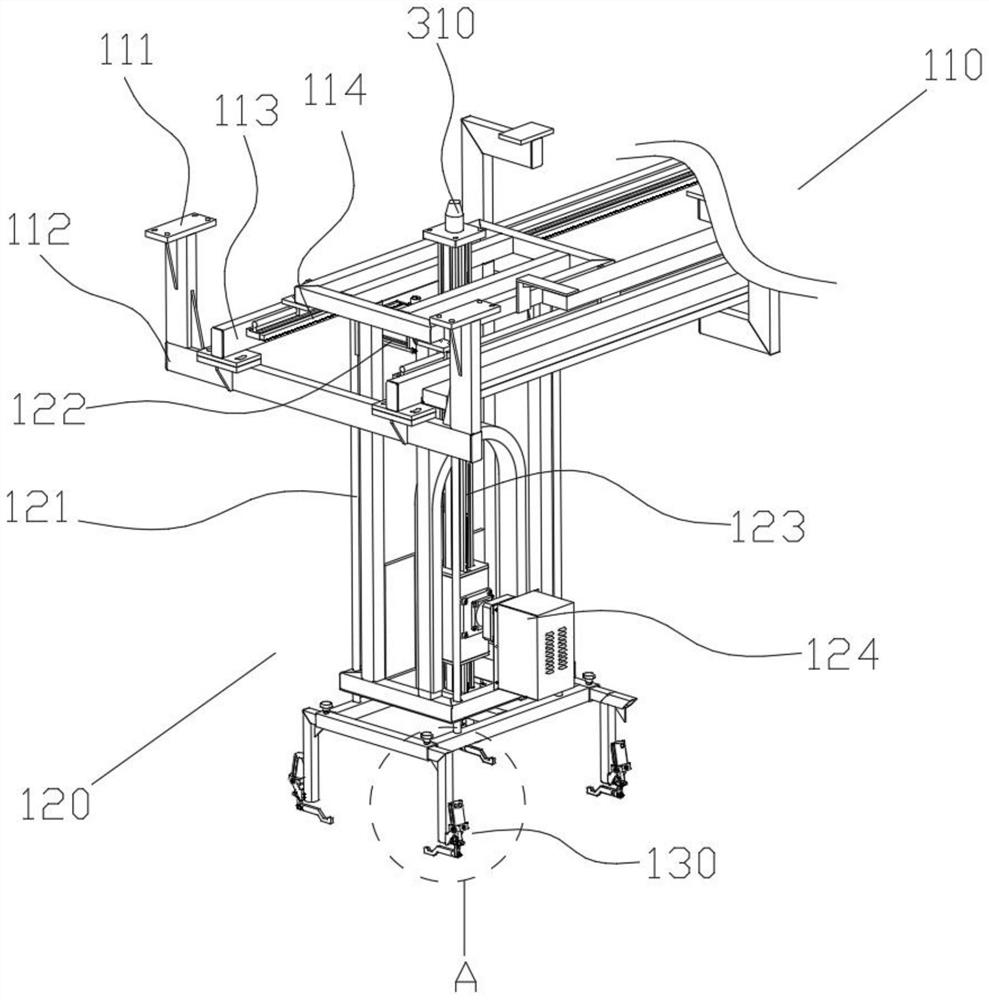

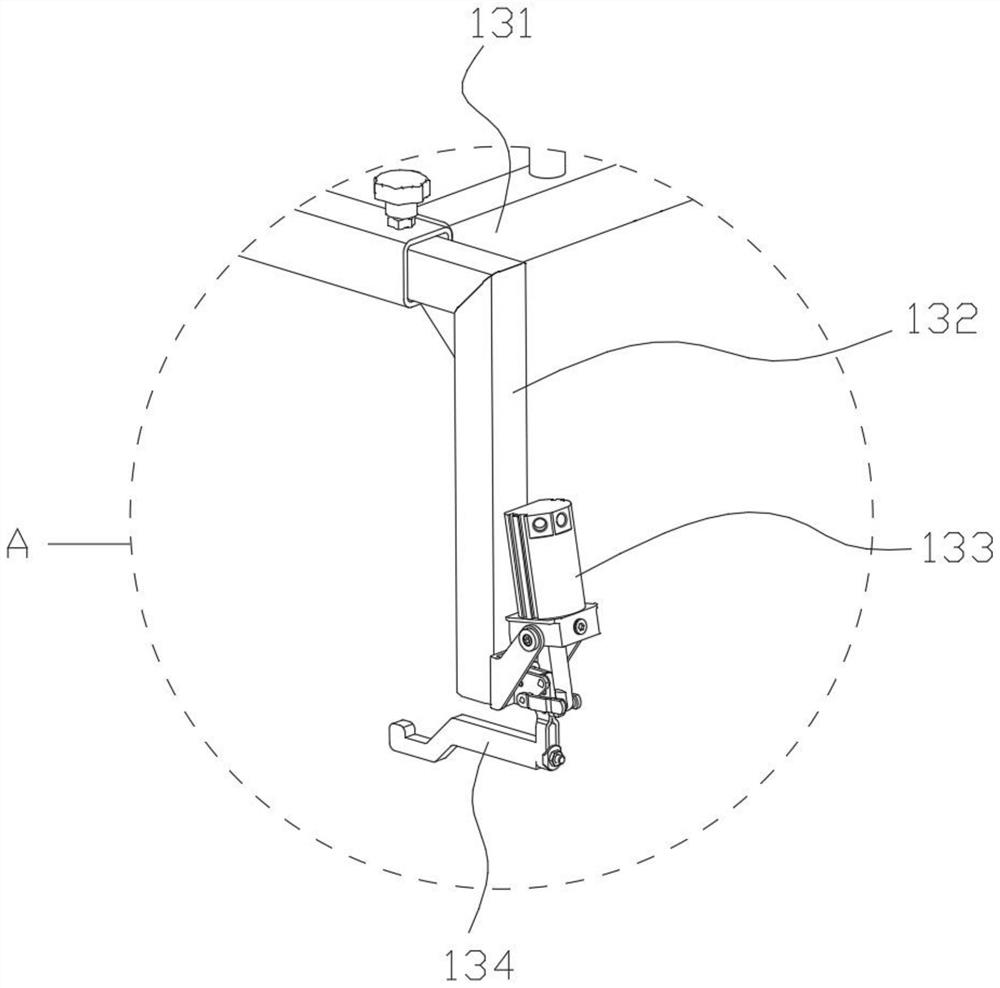

[0025]Such asFigure 1 ~ 5As shown, a coating line automatic transfer machine, including a lifting shift line 100, a drift transfer line 200, a follow-up positioning system 300;

[0026]In the present embodiment, the lifting shift line 100 is provided with two groups and is used in different production lines, including a lifting-filled trace 110, and several slides connected to the lifting transfer slide rail 110. The lifting transfer assembly 120; the lifting shift rail 110 includes several first ceramics 31, a plurality of cross-frame 112, a lifting transfer rail 113, a stroke rack 114; the cross-frame 112 is fixed to a fixed pitch Parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com