Uranium mining method for sandstone uranium ore using surfactant combined with acid in-situ leaching

A technology of surfactant and active agent, which is applied in the field of uranium mining with surfactant combined with acid leaching, can solve the problem that the uranium leaching rate has not been greatly improved, and the recovery rate of high uranium resources and surface activity cannot be met. In order to achieve the effects of high permeation and leaching efficiency, reduced charge density and high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

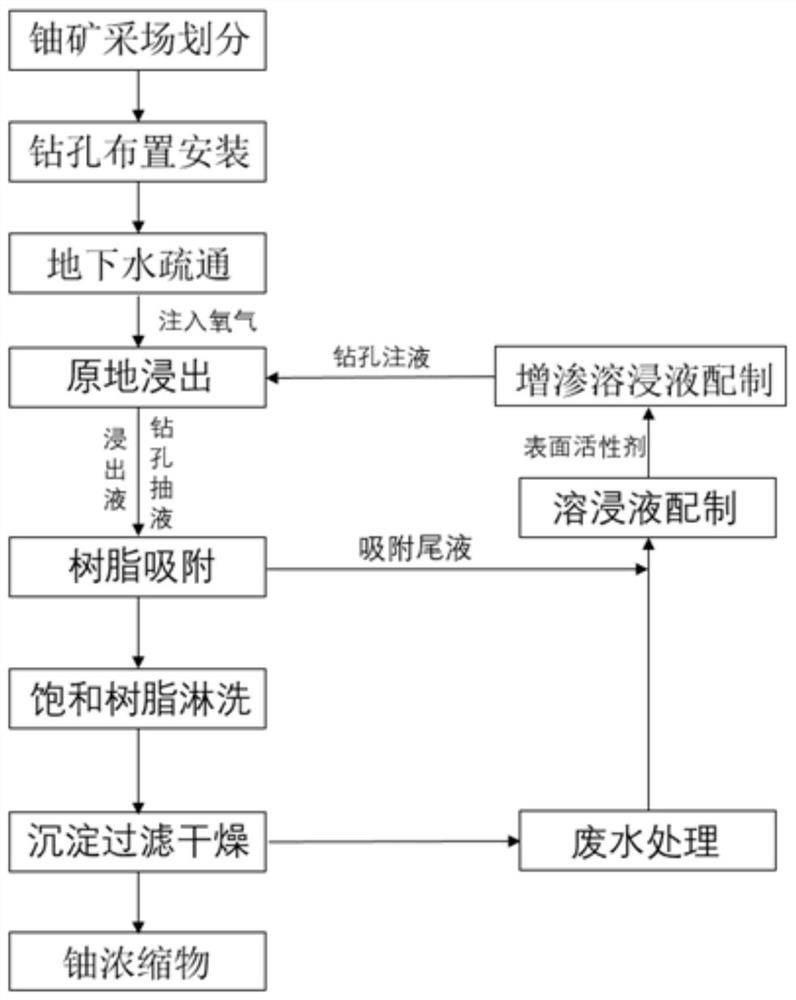

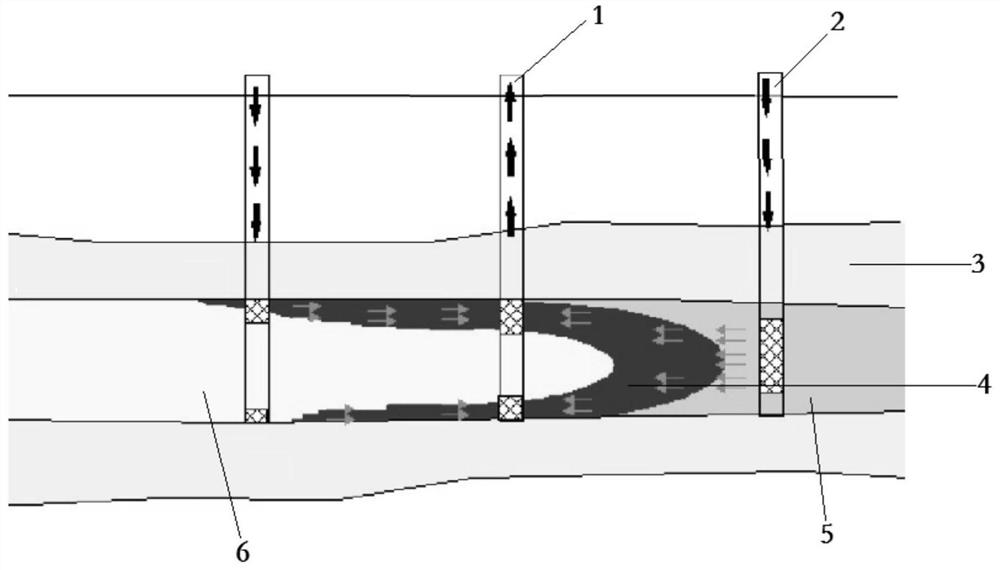

[0053] see figure 2 As shown, this embodiment is based on the geological characteristics of low-permeability sandstone-type uranium deposits: including mudstone 3, uranium-containing rock sand 4 reduced rock sand 5 and altered rock sand 6, the uranium grade is 0.025%, and the permeability coefficient of uranium ore is 0.78~ 0.96m / d, determine the technical route of uranium mining by in-situ leaching, and select the uranium mining method of surfactant combined with acid in-situ leaching (such as figure 1 shown):

[0054] S1. Pretreatment: Carry out uranium mine stope division, layout of pumping and injection production drilling, and pipe network installation; In the mine seam, the mine seam pretreatment is dredged through the groundwater circulation;

[0055] S2, uranium oxide ore layer: After the groundwater cycle is over, inject oxygen into the groundwater in the uranium ore layer as an oxidant, and the oxygen injection concentration is 500mg / L; when the residual oxygen co...

Embodiment 2-5

[0076] The difference from Example 1 is that the mass concentration of the surfactant is different, and the others are the same as in Example 1, and will not be repeated here.

[0077] Table 2 is the mass concentration and performance parameter thereof of embodiment 1-5 tensio-active agent

[0078] Example Mass concentration of surfactant (%) Uranium leaching rate (%) Example 1 0.005 92.21 Example 2 0.001 80.11 Example 3 0.003 88.32 Example 4 0.007 93.16 Example 5 0.01 86.04

[0079] It can be seen from Table 2 that the concentration of compound ternary surfactant has a great influence on the leaching rate of uranium, and the leaching rate of uranium increases first and then decreases with the increase of surfactant concentration. At a concentration of 0.007%, it reaches a peak value of 93.16%. Afterwards, the leaching rate began to decrease with the increase of surfactant concentration, and decreased to 86.04% when the con...

Embodiment 6-8

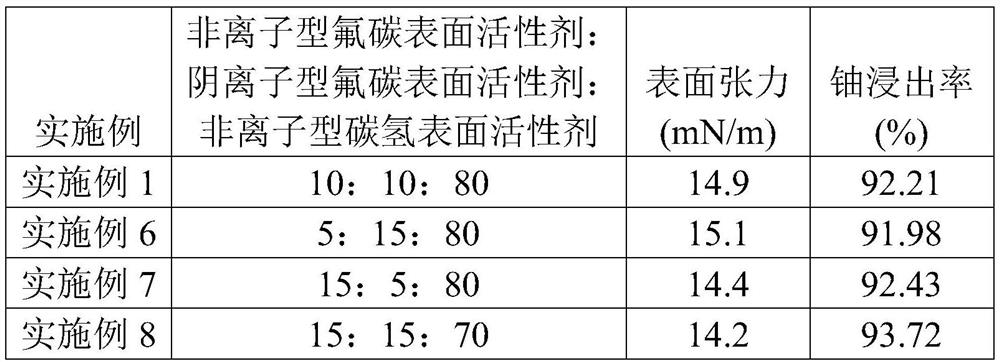

[0082] The difference from Example 1 is that the proportioning ratio of the compounded ternary surfactant is different, and the others are the same as in Example 1, and will not be repeated here.

[0083] Table 3 is the proportioning and performance parameters of embodiment 1 and embodiment 6-8 composite ternary surfactant

[0084]

[0085] It can be seen from Table 3 that the nonionic short carbon chain fluorocarbon surfactant has the best effect on reducing the surface tension of the sulfuric acid immersion solution. This is mainly related to the structure of the fluorocarbon chain on the nonionic short carbon chain fluorocarbon surfactant, which is both oleophobic and hydrophobic, and the interaction between the fluorocarbon chains is weak, so that it exhibits high surface activity in sulfuric acid solution . The composite system used in the present invention can change the physical and chemical properties of a single system, and the composite of fluorocarbon-hydrocarbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com