Nanometer encapsulated halogen-free flame-retardant material and preparation method thereof

A flame retardant material and packaging technology, applied in the field of material science and engineering, can solve the hidden dangers of halogen flame retardant products, increase the burden of environmental management, slow degradation and other problems, achieve excellent printing color rendering effect, excellent weather resistance, and increase resistance. burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

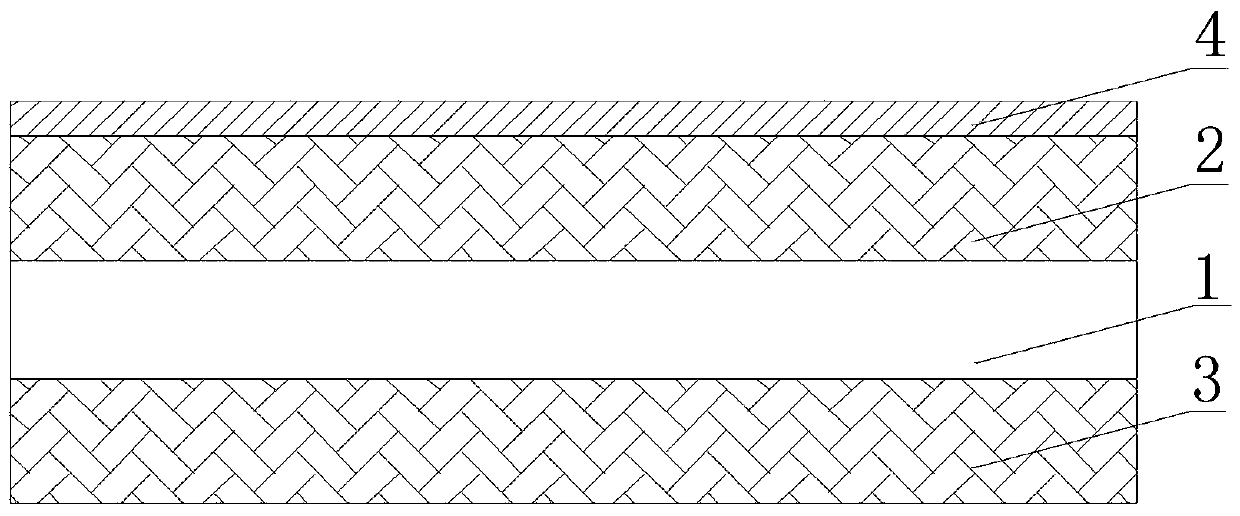

[0059] Such as figure 1 As shown, the nano-encapsulated halogen-free flame-retardant material includes a renewable bio-polyester silk chemical fiber cloth 1, and the two sides of the renewable bio-polyester silk chemical fiber cloth 1 are respectively coated with a nano-encapsulated halogen-free flame-retardant coating A2 and synergistic The expanded halogen-free flame-retardant coating B3 is coated with a cationic ink-absorbing color-developing coating C4 on the outside of the nano-encapsulated halogen-free flame-retardant coating A2.

[0060] The preparation method of the nano-encapsulated halogen-free flame retardant material, in parts by mass, comprises the following steps:

[0061] (1) Weaving renewable bio-polyester silk chemical fiber cloth:

[0062] (11) Mix 80 parts of polyethylene terephthalate, 5 parts of polyhydroxyalkanoate, and 10 parts of polylactic acid, and spin to produce renewable bio-polyester yarn;

[0063] (12) Manufacture and weave renewable bio-polyes...

specific Embodiment 2

[0091] Such as figure 1 As shown, the nano-encapsulated halogen-free flame-retardant material includes a renewable bio-polyester silk chemical fiber cloth 1, and the two sides of the renewable bio-polyester silk chemical fiber cloth 1 are respectively coated with a nano-encapsulated halogen-free flame-retardant coating A2 and synergistic The expanded halogen-free flame-retardant coating B3 is coated with a cationic ink-absorbing color-developing coating C4 on the outside of the nano-encapsulated halogen-free flame-retardant coating A2.

[0092] The preparation method of the nano-encapsulated halogen-free flame retardant material, in parts by mass, comprises the following steps:

[0093] (1) Weaving renewable bio-polyester silk chemical fiber cloth:

[0094] (11) Mix 85 parts of polyethylene terephthalate, 8 parts of polyhydroxyalkanoate, and 15 parts of polylactic acid, and spin to produce renewable bio-polyester yarn;

[0095] (12) Manufacture and weave renewable bio-polyes...

specific Embodiment 3

[0123] Such as figure 1 As shown, the nano-encapsulated halogen-free flame-retardant material includes a renewable bio-polyester silk chemical fiber cloth 1, and the two sides of the renewable bio-polyester silk chemical fiber cloth 1 are respectively coated with a nano-encapsulated halogen-free flame-retardant coating A2 and synergistic The expanded halogen-free flame-retardant coating B3 is coated with a cationic ink-absorbing color-developing coating C4 on the outside of the nano-encapsulated halogen-free flame-retardant coating A2.

[0124] The preparation method of the nano-encapsulated halogen-free flame retardant material, in parts by mass, comprises the following steps:

[0125] (1) Weaving renewable bio-polyester silk chemical fiber cloth:

[0126] (11) Mix 82 parts of polyethylene terephthalate, 6 parts of polyhydroxy fatty acid ester, and 12 parts of polylactic acid, and spin to produce renewable bio-polyester yarn;

[0127] (12) Manufacture and weave renewable bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com