Transparent photocuring ink for 3D ink-jetting printing and preparation method thereof

An inkjet printing and light curing technology, applied in the field of printing, can solve the problems of easy yellowing, molecular chain breakage and opacity of printed products, and achieve the effect of excellent printing effect, excellent application performance and not easy to yellowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

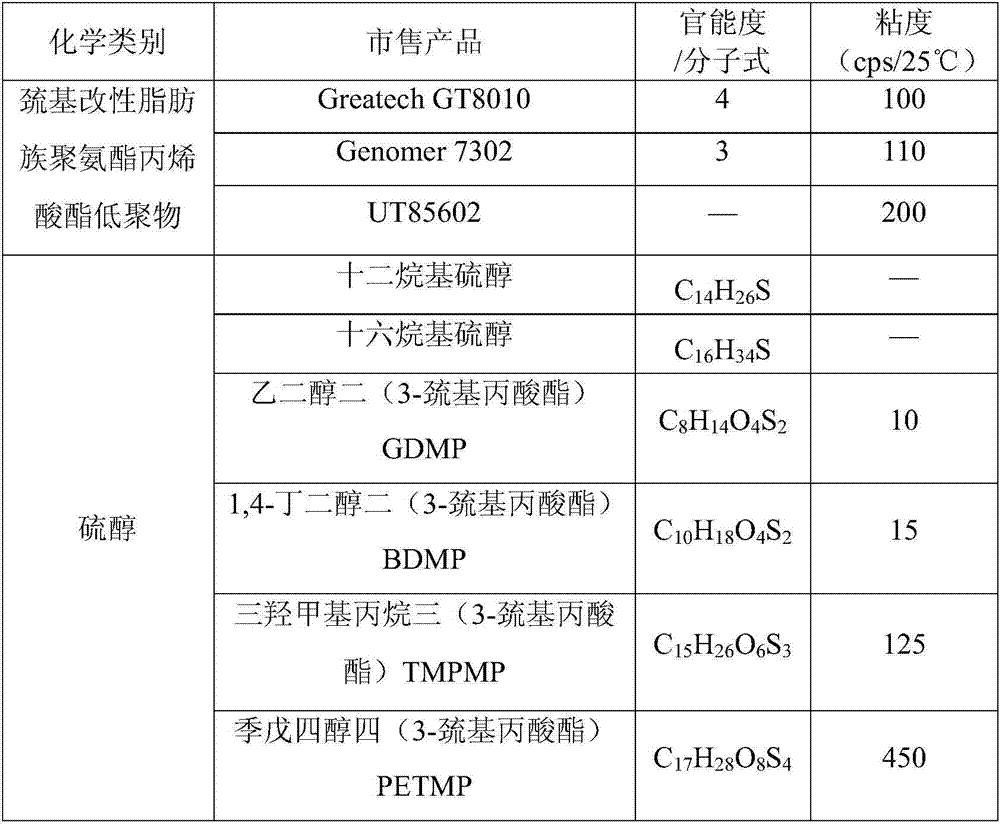

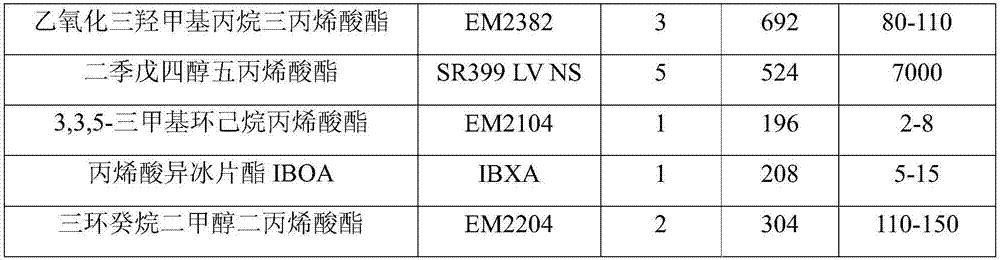

Method used

Image

Examples

Embodiment 1

[0058]

[0059] Preparation:

[0060](1) Put 30g of isobornyl acrylate IBOA, 18.68g of tricyclodecane dimethanol diacrylate EM2204, 48g of mercapto-modified aliphatic urethane acrylate oligomer Genomer 7302, 0.02g of BYK-377 and 0.5g of GENORAD16 in In the glass container, use a stirrer to stir to obtain a uniformly mixed first mixture; then add 0.8gTPO radical photoinitiator and 2g184 free radical photoinitiator to the first mixture and continue stirring until the free radical photoinitiator is completely dissolved to obtain the second mixture;

[0061] (2) Carry out primary filtration with a 0.45 μm glass fiber membrane, and then perform secondary filtration with a 0.22 μm PP membrane to obtain a filtrate;

[0062] (3) Under a vacuum degree of 0.1 MPa, filter under reduced pressure for 1 hour to remove air bubbles in the filtrate, and finally obtain a photocurable transparent ink for 3D inkjet printing.

[0063] Carry out performance test to the 3D inkjet printing photo...

Embodiment 2

[0072]

[0073] Preparation:

[0074] The preparation method of the photocurable transparent ink for 3D inkjet printing in this embodiment is basically the same as that of Embodiment 1, except that the time for decompression and degassing is adjusted to 2 hours.

[0075] According to the same test method as in Example 1, the performance test of the 3D inkjet printing photocurable transparent ink in this example is carried out, and the test results are shown in surface 1 .

Embodiment 3

[0077]

[0078] Preparation:

[0079] The preparation method of the 3D inkjet printing photocurable transparent ink in this example is basically the same as that of Example 1, except that the temperature of the 3D inkjet printing photocurable transparent ink is heated to 40-60°C for 1 hour by heating and degassing .

[0080] According to the same test method as in Example 1, the performance test of the 3D inkjet printing photocurable transparent ink in this example is carried out, and the test results are shown in surface 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com